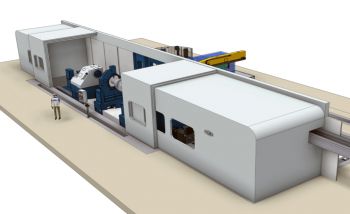

ULTRATURN MC

Previously, machining centers on the market were used for a maximum workpiece weight of up to 15t.

With the ULTRATURN MC, GEORG approaches a new machining range, which has not been realized so far related to workpiece size and weight, accuracies and cutting forces combined with the automatic workpiece measuring unit.

The ULTRATURN MC will set new standards in terms of profitability and productivity, because the reduction of downtime for machining of large workpiece has more impacts than downtime for smaller component.

The horizontal machining center ULTRATURN features

- Complete machining by turning, drilling, milling, grinding and measuring on one machine

- Automatic tool change with robot system

- Automatic attachment changing

- CNC-controlled 2-point-workpiece measuring system

- Highest long-term accuracy due to 3 hydrostatic guided linear axes

- Rough and finish machining on one machine

- Complete machine enclosure with integrated coolant mist exhaust system

- NC controlled and high-precision C-axis drive with free backlash clamping unit

- NC controlled A-axis

The machining center ULTRATURN will interest potential customers among turbine and generator manufacturers, crankshaft and driving shaft producers, forges, large gear manufacturers and the general machine building industry.

EN

EN