10/07/23

Parts 3D printed with photopolymer resins almost always need post-processing once the printing is done to ensure the target properties declared by the material’s manufacturer. The first stage of this post-processing is cleaning the model to remove excessive liquid resin remaining on its surfaces. To make cleaning resin 3D printed parts easier and faster, Zortrax designed the Zortrax Cleaning Station. Here’s everything that makes this machine unique.

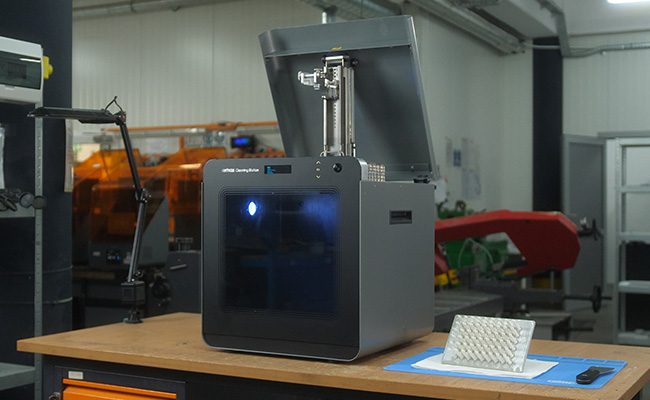

Zortrax Cleaning Station – an automatic device used to post-process resin 3D prints.

Liquid polymer resins are not easy to remove. They stick to surfaces, get into every little crevice, and their scent is usually unpleasant. Cleaning solvents like isopropyl alcohol (IPA), sometimes preceded by rinsing the model with agents based on glycol, is the most common way of getting rid of them. Doing it properly is very important since resin 3D printed parts almost always undergo additional UV curing after they are cleaned. This means each drop of liquid 3D printing resin that remains on a 3D printed part gets cured and turns into solid plastic thus ruining the dimensional accuracy. This process was presented in detail in the article: Zortrax Curing Station: An Industrial Grade UV Curing Device for Resin 3D Prints.

Zortrax Cleaning Station is a device made to take care of the cleaning process in a clever and simpler way. All it takes is turning the device on, filling it with appropriate cleaning agent, placing the models in a cleaning basket, and choosing the right cleaning parameters (suggested by the machine). Once the process is done, the models are automatically removed from the cleaning agent and are ready for further post-processing steps.

And there is a lot of engineering ingenuity behind making it that simple.

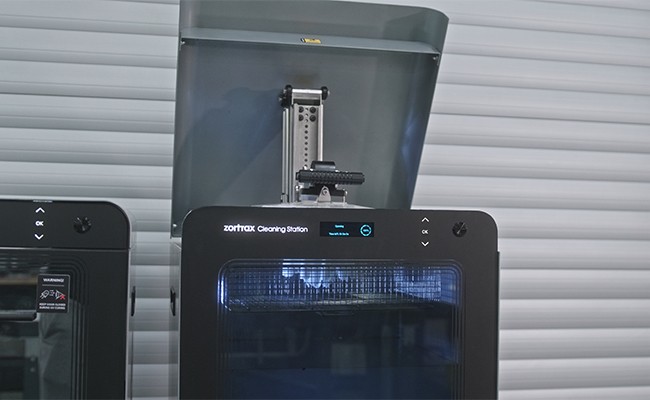

Traditionally, resin 3D printing was used for printing very precise but small parts. In the recent years, however, there is a noticeable trend towards making resin 3D printers larger and larger to enable manufacturing of bigger models. A large industrial-grade workspace is a feature of Zortrax Inkspire 2, which is the most refined resin 3D printer on the market. This is why Zortrax engineering team future-proofed the Cleaning Station by making it large enough to accommodate big parts. The usable workspace of the Cleaning Station measures 300 x 210 x 270 mm. The machine can also take up to 18 liters of solvent. This means that it’s possible to clean the output of a vast majority of modern resin 3D printers in a single cleaning session.

Most cleaning devices available on the market today rely on an ultrasonic technology which uses ultrasounds emitted at a specific frequency to set the solvent in motion. Ultrasonic cleaners do not need that many moving parts and are therefore quite cheap. The downside is that they can damage minuscule features and details present on the cleaned models. Since resin 3D printing is mostly about utmost precision, Zortrax engineering team opted for a more high-end solution based on a custom-made rotor. The rotor is located at the bottom of the Cleaning Staton’s cleaning chamber. Blade design and software regulated rotation speed are optimized and adjusted to certain resin 3D prints to offer fast and efficient yet delicate cleaning which preserves all the details in the models.

IPA is the best possible solvent for a vast majority of photopolymer resins. Some materials, however, require a two-stage cleaning process where a model is rinsed in glycol-based agent first, and cleaned in standard IPA afterwards. Cleaning devices available on the market today are usually compatible with IPA which is the most popular solvent, and are not designed to work with agents based on glycol. With Zortrax Cleaning Station it is possible to use both glycol-based agents and IPA to perform the two-stage cleaning process in one device.

Zortrax Cleaning Station is compatible with the most popular solvents in resin 3D printing – IPA and glycol.

Of course, the solvent has to be changed between the first and the second stage of resin 3D prints cleaning. In applications where maximizing output is critical, it is recommended to use two Cleaning Stations for the two-stage cleaning – one working with glycol and the other working with IPA.

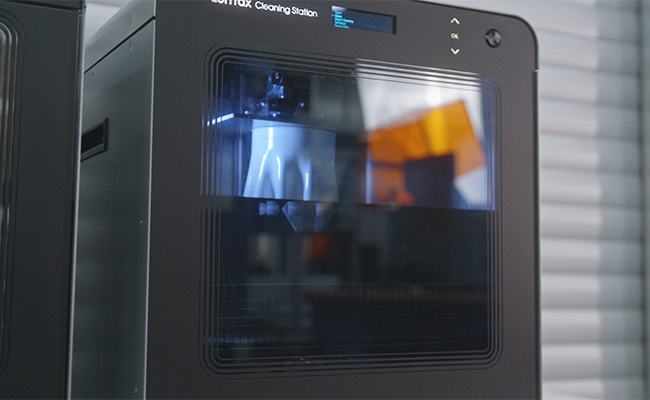

Solvents like IPA used in cleaning devices have limited lifespan. Each time they are used, they get mixed up with the resin and need to be changed periodically. The Cleaning Station has an advanced filtering system designed to keep the solvent clean for as long as possible. During the cleaning process, the cleaning agent is pushed through two filters – a 1 µm polypropylene cartridge and 150 µm stainless steel mesh. Moreover, the filtering system irradiates the solvent with UV light to solidify the resin and make it easier to filter out.

Advanced filtering system keeps the solvent clean for multiple cleaning sessions.

This way, it is possible to go through multiple cleaning sessions without changing the solvent. Once in a while it is necessary to change easily replaceable filters to keep the Cleaning Station running like brand new for years.

Finally, the Cleaning Station is very price-competitive. Compared to Form Wash L, which is its closest competitor, it costs over 700 USD less for a better spec. For example, with a similar workspace, the Form Wash L does not have any filtering systems for the cleaning fluids. This means the IPA needs to be changed more often, translating into more time and money spent on maintenance.