22/02/23

Summary

Falectra is an automotive company founded by Piotr Krzyczkowski, which is recognized for building the first Polish electric motorbike. The brand is also involved in vehicle reproduction, and has recently created a classic scooter called Be-e, based on the WFM M50, a Polish motorbike from the 1960s. 3D printing has played a significant part in Falectra’s business activity since the very beginning and it’s been no different for the Be-e project. The company has used Zortrax M200 Plus, Zortrax Inventure and Zortrax M300 Plus desktop 3D printers for the reproduction of this vintage scooter.

The idea for the Be-e scooter project emerged in parallel with the development of the Falectra e-motorbike, and during their collaboration with 911 Garage on the “Remastered” Porsche series, a variation on classic 911 models along with modern details. When work on the Falectra stalled, for reasons beyond the company’s control, the Be-e was put to the forefront. As there is the ever-growing fashion for restomods, Krzyczkowski knew such a project was going to grasp the attention of automotive enthusiasts. He also knew he wanted to base his new scooter on a WFM’s 60’s flagship model and use his favorite additive manufacturing technology for that purpose. The only issue that puzzled him was the project’s name. The designer wanted it to be associated with the original model, as well as reflect what the company specializes in. “Be-e” seemed to be a perfect choice: “Vespa is Latin for wasp, Bee is English for bee, and Be-e, in our case, is an extension of “Be electric,” Piotr Krzyczkowski, Falectra founder explains. Now, what exactly did the creative process look like in this case?

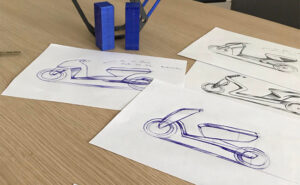

First, Piotr sketched the entire body of the scooter. “We decided to take inspiration from the lump, but simplify it – getting rid of elements that shot the overall form,” says Piotr Krzyczkowski. Then, after preparing the first sketches of the particular elements, the first visualizations began to emerge – the designer decided, e.g, on what details to implement, what is missing from the frame, or where to employ the functional items, such as rear lighting. The creator used Autodesk Alias CAD software.

After sketching the final frame, Piotr proceeded to build the prototype; the outer panels of the overall body were made of laminate, and then, after fitting it to the frame, the whole thing was 3D scanned. Thanks to the 3D model, Falectra was able to make precise elements with 3D printing technology. Once the models were prepared for 3D printing in Z-SUITE software, using High quality settings and 30% infill, the 3D printing process began. “We’ve made all the exterior components – lamp housings, front fender fins, display housing on Zortrax M200 Plus. Thanks to Zortrax M300 Plus, our workhorse, due to its big workspace, we were able to make larger elements, like block intakes. Key fobs or scooter-shaped figures, in turn, were made on Zortrax Inventure,” Falectra owner underlines. The material chosen for the target parts was Z-PETG in Grey.

Then, Piotr smoothed the 3D printed parts for a scooter with a spray spatula and applied a base coat on their surface. In the next step, to add even more depth to the color, and a slightly glossy finish, the models were coated with an additional layer of a transparent coat and left to dry. At this point, the creator could move on to one of his favourite activities during the process of creating functional vehicle components – assembling the parts. “I adore the process of putting together a large piece 3D printed from several smaller elements. It reminds me a bit of assembling model airplanes from my childhood, a nostalgic feeling I always enjoy,” Piotr notices.

According to Piotr Krzyczkowski, 3D printing offers possibilities that simply didn’t exist before. He especially highlights rapid prototyping aspect, invaluable in automotive, where parts often have to undergo extensive tests as regards their mechanical properties, or have be produced on-the-spot, due to a certain component shortage. “There’s nothing more wonderful, in my opinion, than when you have everything in-house. You need a part, you sit down at the computer, model it, and in just a few hours you hold a physical part in your hand for fitting, or for a target use”. Falectra founder also notices how versatile this manufacturing method is for the automotive industry: “In my opinion, 3D printing works brilliantly in many parts of the automotive industry, from the design itself, to making components for existing cars, to customized parts for individual customers. 3D printing has saved me a ton of time, as well as money that I would have had to spend driving around to various subcontractors to have the aforementioned parts made by the traditional methods,” he underlines.

He recommends from his own experience, especially Zortrax M300 Plus. “Zortrax M300 Plus is a true workhorse for printing quality large-sized parts. I would recommend this equipment to both automotive professionals, and car-tuning fans, who want to print parts that will have physical use in prototypes close to the production version,” Piotr Krzyczkowski concludes.

If it were not for 3D printing technology, the process of building decorative and functional elements would have taken much longer and would not have been so precise. By scanning the main body of the scooter and measuring the commercial elements, it was possible to model all the complementary elements. The target scooter with 3D printed parts came out so well, that, having presented it, Falectra gained interest from clients all over the world and it is currently occupied manufacturing several further Be-e copies for the newly received commissions.