ADDITIV3X carries out on your behalf services ranging from the design to the production of parts, through non-destructive testing.

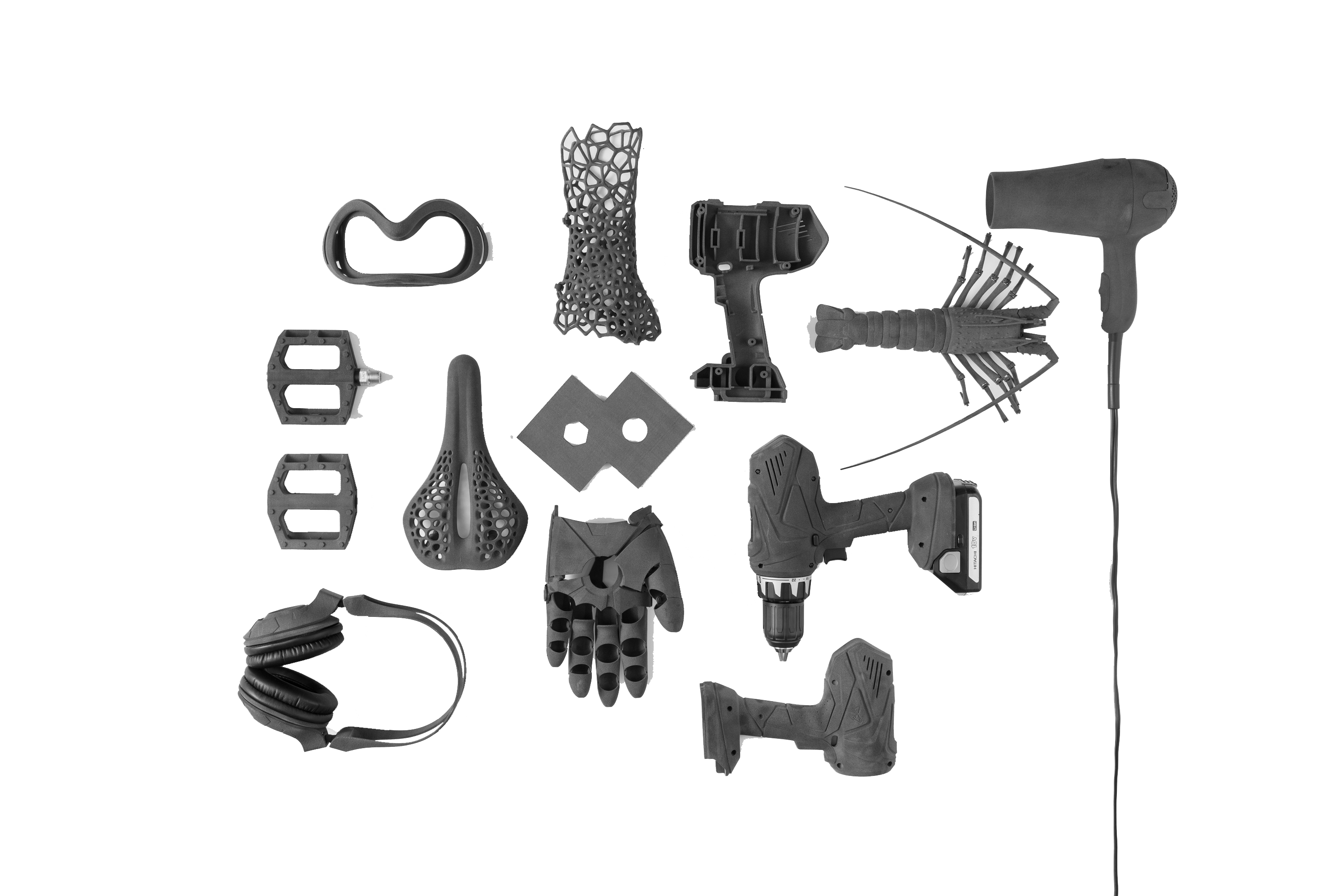

Additive manufacturing changes the way products are made, allowing manufacturers to design revolutionary products that can not be made using traditional methods. Additive production methods can offer advantages, such as saving weight, better performance, or simplified assemblies.

ADDITIV3X application engineers design products to be made in additive manufacturing by taking advantage of the opportunities provided by these processes, while taking into account the new constraints they induce.

We realize for you the following services:

Our application engineers rely on the Siemens NX software suite, which enables data flow management without breaking the digital chain, from design to manufacturing.

Read the Siemens press release by clicking HERE.

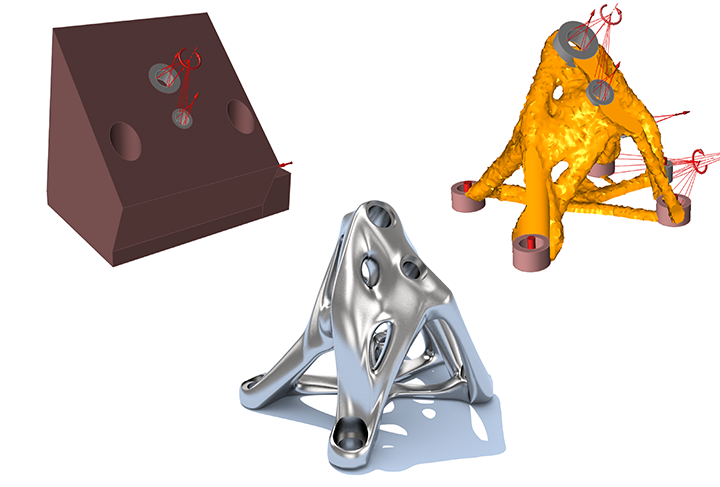

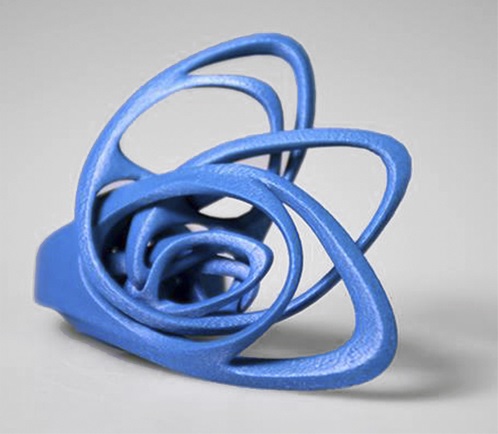

ADDITIV3X propose to optimize the design of your parts, by the realization of topological optimizations or the generation of lattices structures. We help you get the most out of additive manufacturing by adding features to your parts, or reducing the number of assemblies, for example.

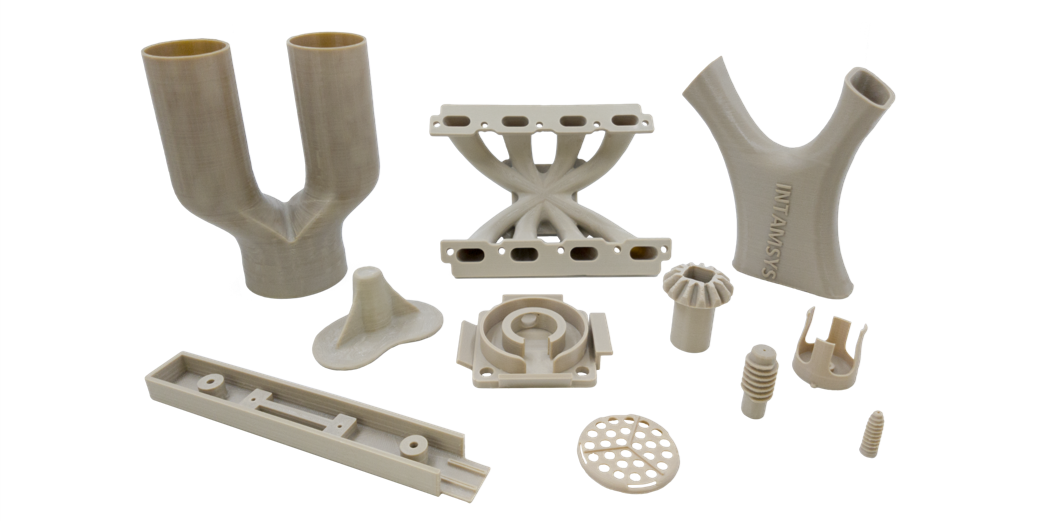

ADDITIV3X is able to produce PEEK parts, a material that can withstand continuous operating temperatures of 250 ° C. With a high impact resistance, its breaking strength of 80 MPa allows a large number of mechanical applications. Its applications are numerous, particularly in the medical, aeronautical or automotive sector.

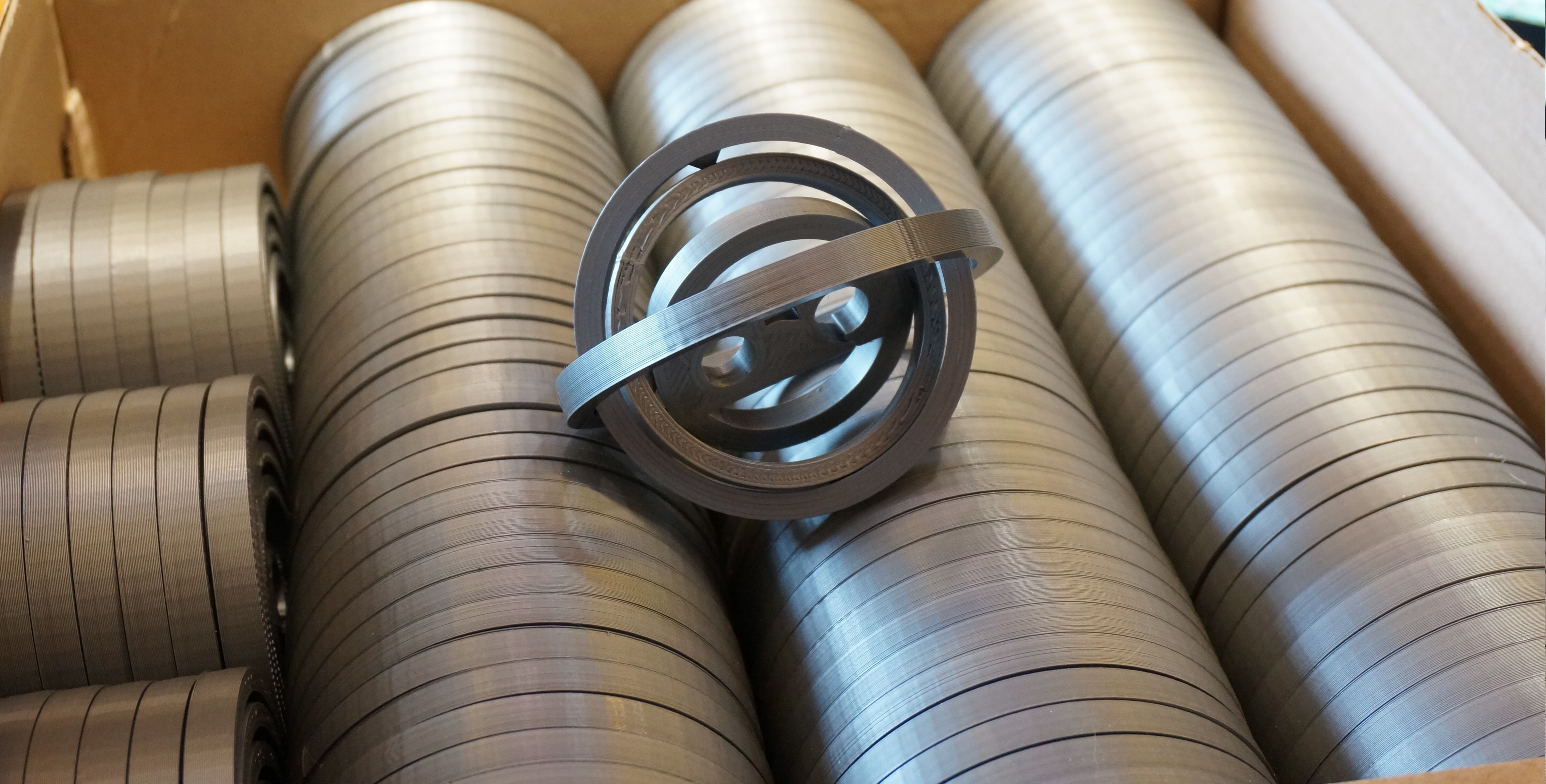

3D printing of parts on multi-head FDM machines makes it possible to produce series of parts in quantities of up to several thousand pieces and at particularly competitive prices. The applications of this technology are numerous, both for industry and marketing!

The 3D printing of wax parts makes it possible to make imprints that can be used in a lost wax foundry. The quality of the surface finish obtained on the wax piece makes this technique particularly suitable for producing small metal parts with complex geometries and high levels of detail.

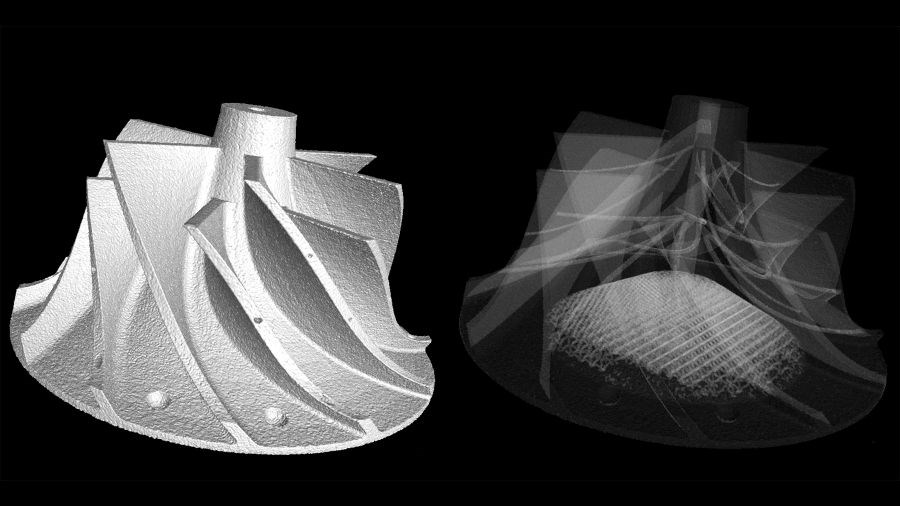

ADDITIV3X performs scan services. Depending on your applications, we are able to reconstruct the surfaces, or to carry out a dimensional control. 3D scanning also allows you to reproduce parts by 3D printing.

ADDITIV3X selects the most appropriate control methods for parts made in additive manufacturing, taking into account your criticality requirements. We control your parts, write a control report, and validate the quality of your productions. We are able to perform tomographies, detect possible porosities in the room, or perform dimensional checks.