This activity is the result of a strong demand from users for technical assistance in terms of training and support for scaling up or for some specific application developments.

ADDITIV3X work across the entire supply and value chain helping the user to accelerate the integration of transversal and complementary technologies in Additive Manufacturing.

Consult our brochure by clicking HERE !

ADDITIV3X supports you in your implementation of additive manufacturing processes in your company.

Multistation creates a partnership with Segula Technologies in order to extend our mutual product engineering capabilities.

Read the Segula press release by clicking HERE.

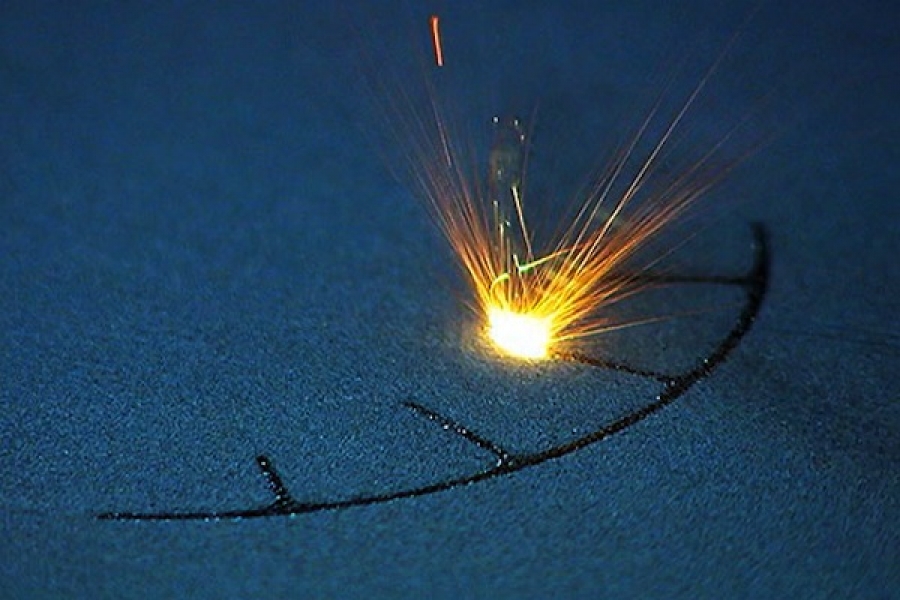

ADDITIV3X and Segula Technologies are working together to provide the cross-functional skills needed to deliver specific engineering services to additive manufacturing users.This partnership allows clients of both companies to benefit from a single point of contact who is able to provide all the necessary solutions for the implementation and industrialization of the processes of the entire manufacturing value chain.This partnership covers the various metal and non-metal additive manufacturing processes with a particular focus on Design for Additive Manufacturing (DFAM) design methods and non-destructive testing methods.

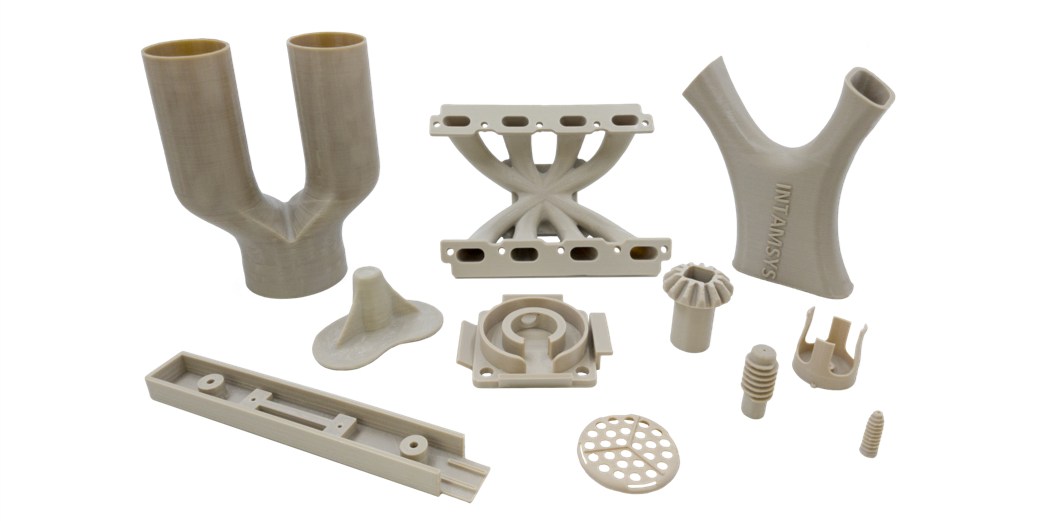

Thanks to our proven methodology, we are able to analyze catalogs containing several thousand of parts, to extract the parts that can be manufactured by additive manufacturing, and to select for them the most appropriate technologies. We perform detailed case studies on a representative sample of parts, and evaluate the potential gains over the entire catalog.

From the ERP to production preparation, to topological optimization software or to the creation of lattices, extremely useful in additive manufacturing, ADDITIV3X supports you in the definition of the digital chain and the choice of software adapted to your applications.

You wonder about the choice of the best process or your installation does not meet the objectives initially expected? We provide you with a diagnosis ranging from manufacturing methods, equipment settings and calibrations, to workshop flows. We study the impact of each link in the value chain of additive manufacturing on the productivity and quality of your parts.

ADDITIV3X carries out HSE audits within your company, during which we validate the compliance of your practices and equipment with the applicable regulations and its latest developments in the field of additive manufacturing.We advise you for your waste treatment policy.We train your staff in HSE best practices.