15/10/23

It is where Scantech’s portable 3D laser scanners come in.

These 3D scanners offer highly efficient and precise 3D measurements for race car components. With 3D scanning technology, users can ensure optimal and safe performance for race cars. It also helps users save time and money by streamlining regular inspection and maintenance workflows.

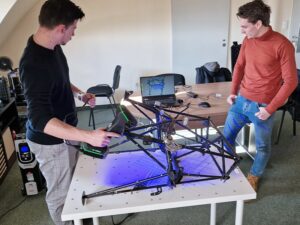

3D scanning a rear frame

Scantech’s reseller DDD – Control helped the racing team BME Motorsport to 3D scan race car components precisely and create 3D models to ensure individual components are in good condition and gain insights into actual working conditions.

The 3D laser scanner used in this case is KSCAN-Magic, one of the first 3D scanners that combine infrared and blue lasers into one instrument. With two sets of high-definition industrial cameras, it can conduct 3D scanning meticulously.

It offers five standard working modes:

race car rear frame, 3D scanning

The crankshaft is a mechanical part that turns the reciprocating movement of the pistons into rotational motion. Using methods such as strength simulations and balance testing, engineers can evaluate and optimize the design and performance of the crankshaft.

As the crankshaft features complicated geometries, an accurate model made out of the crankshaft is crucial to ensure further precise strength simulations and balance testing.

The engineer from DDD – Control used Scantech’s handheld composite 3D scanner KSCAN-Magic to capture the geometry of the crankshaft from different angles and saved the scan data.

The 3D data was imported to 3D modeling software to remodel the crankshaft. The following shows the crankshaft model based on the scan data.

Crankshaft model based on the scan

A rear frame affects the car’s handling, stability, and performance. A well-designed and properly maintained rear frame can help a car achieve optimal balance and aerodynamics.

After a year of service, a rear frame may be deformed, which can compromise the safety and efficiency of the racing car.

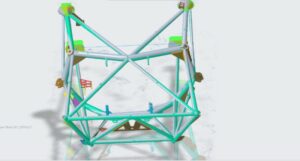

Comparison of the condition of the rear frame last year and this year

The engineer used KSCAN-Magic to capture the 3D data of the rear frame. The data captured were compared to the data obtained a year earlier. By comparing, they checked whether the frame suffered deformation during last year’s racing season.

In addition, it helped identify the extent of damage and checked if it was suitable for another racing season. It can be seen that it did not suffer major deformation and is competitive this season as well.

Furthermore, they performed a scan of the lower engine block. For such complex parts, it is a significant advantage to create a CAD model based on the 3D data generated by the 3D scanner rather than modeling them from scratch.

Lower engine block model based on the scan

The geometry of the engine block is very intricate, and design, for instance, an oil system in it without a model, is a big challenge. The scanned models facilitated the placement of the oil system and enabled them to verify if all the planned parts fit or if further modifications were required.

Before production, the inner surface of the monocoque was damaged, resulting in minor inaccuracies in the final piece.

Monocoque (composite frame) model based on the scan

Hence, it was essential to scan the monocoque, so as to compare the actual manufactured piece with the model and detect any potential errors. Moreover, they were able to readily verify the precise position of the connection points of the chassis and frame by comparing the two models.

KSCAN-Magic 3D scanner stands out among its competitors due to its composite functions, which suit well for 3D scanning confined areas, intricate details, and large-size parts. It can be set up on-site to conduct measurements anywhere you need, as it is portable and compact.

With a measurement rate of up to 1.65 million measurements/s and an accuracy of up to 0.020 mm, it can ensure the 3D data captured can meet the stringent requirements of users.

Thanks to the high-precision measurements of the 3D scanner, the engineer obtained 3D data with an accuracy of up to 15-30 microns to create precise models.

As a result, the CAD models created were as realistic as possible. High-tech 3D scanning enhances the efficiency and convenience of maintaining a racing car to achieve optimal performance.