27/11/23

Brucom Wiring Harness, a renowned manufacturer and supplier of electrical and wiring assemblies for white goods vehicles in the UK, has recently joined forces with Raise3D to harness the power of their cutting-edge 3D printing technology. With over two decades of experience in providing wiring harness and cable assembly systems in machinery, technology, training and engineering, with more than 200 customers and over 5000 different product lines using their products in many market sectors. Brucom is committed to becoming a world-class provider of wiring harness and cable assembly systems. By incorporating Raise3D’s advanced Fused Filament Fabrication (FFF) 3D printers into their operations, Brucom aims to revolutionize their production processes and offer customized solutions to their diverse customer base.

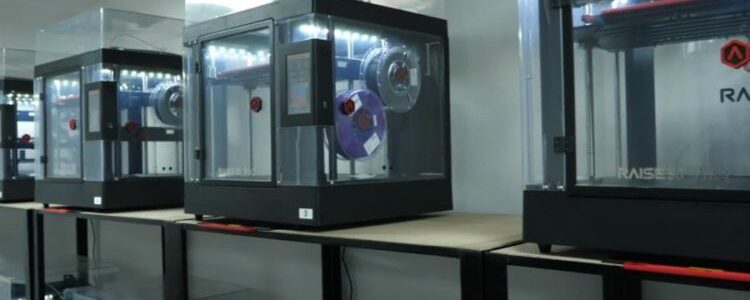

As part of their collaboration, Brucom has made a significant investment in 12 state-of-the-art Raise3D Pro2 3D printers. These cutting-edge printers serve as valuable tools in the design and development of jigs and connector systems for automotive and white goods vehicles. Leading the charge in this endeavor is Stefan Heymann, an accomplished R&D engineer at Brucom. With his expertise and the capabilities of the Raise3D Pro2 printers, Heymann and his team can seamlessly reverse engineer existing parts and leverage 3D printing to efficiently manufacture connectors that were once prohibitively challenging, expensive, or even unattainable through traditional manufacturing methods.

A standout feature of the Raise3D Pro2 printers, as noted by Simon Twiner, an engineering manager at Brucom, is their exceptional user-friendliness. Despite having minimal prior exposure to 3D printing technology, Twiner quickly adapted to operating the Raise3D printers. This ease of use has enabled Brucom’s team to rapidly integrate 3D printing into their workflow, expediting the implementation of this groundbreaking technology.

One of the primary advantages that Brucom has experienced through their partnership with Raise3D is the ability to produce highly customized items while saving significant amounts of time. Twiner’s team can now manufacture test jigs and bespoke connectors tailored to both customer specifications and internal requirements. The flexibility offered by additive manufacturing empowers Brucom to scale production effortlessly, ensuring that they can meet customer needs with exceptional quality and speed. While Brucom currently employs Raise3D Premium PLA for their prints, the Pro2 printers are compatible with a wide range of filaments through the Open Filament Program (OFP), a collaboration between Raise3D and filament manufacturers. This compatibility expands the material options available to Brucom, allowing for even greater versatility and optimization in their production processes.

Stefan Heymann, the R&D engineer at Brucom, emphasizes the remarkable cost-efficiency and productivity of the Raise3D Pro2 printers. These printers are entirely self-contained, eliminating concerns about the surrounding environment. Moreover, their substantial build volume and unparalleled print quality surpass the capabilities of alternative options on the market. Currently, Brucom’s twelve printers produce an average of 100 to 1000 prints per day, enabling rapid prototyping and on-demand part production. The exceptional performance of the Raise3D Pro2 printers has far exceeded Brucom’s expectations, with the machines paying for themselves in a mere three months, surpassing the initial return on investment (ROI) projection of 6-12 months.

The benefits of in-house production facilitated by the Raise3D Pro2 printers are also significant for Brucom. Dom Riley, a Plastics Production Operative at Brucom, highlights the advantages of being able to manufacture parts internally, eliminating the dependence on external companies or international suppliers. This not only saves time but also grants Brucom the autonomy to make modifications and iterate on part designs promptly. The streamlined workflow and reduced lead times contribute to increased efficiency and a competitive edge for Brucom in the market.

The collaboration between Brucom Wiring Harness and Raise3D has yielded substantial advantages through the integration of 3D printing technology. The ability to scale production, achieve faster ROI, and produce customized parts in-house has transformed 3D printing into a pivotal tool for Brucom. As 3D printing gains popularity in various industries, Raise3D’s reliability, innovation, and filament compatibility position them as a valuable partner for Brucom and other global enterprises.

The case is shared by 3DGBIRE, which is Raise3D’s sales partner in the UK.