7/03/24

When it comes to revolutionizing the automotive industry with aftermarket gauges, one company stands out: Speedhut. With high-end components and cutting-edge manufacturing processes, their company is all about supporting gauge customization and handing the controls off to the everyday driver.

The heart of their innovation lies in Raise3D 3D printers. These cutting-edge printers have transformed the way Speedhut engineers develop and produce their high-quality gauges, from prototyping to assembly.

“It’s nice to use it to test the fit and finish of a lot of parts,” said Speedhut Engineer Jonny Wachter. “But we also use it to make a lot of production tools for the manufacturing processes.”

Raise3D printers have transformed the way Speedhut engineers develop and produce their high-quality gauges.

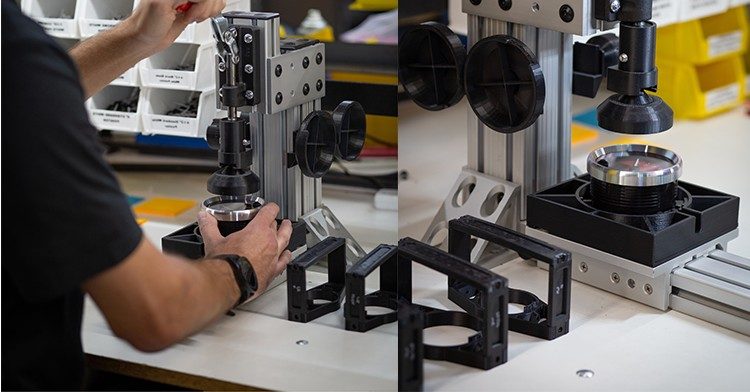

At Speedhut, prototyping is a crucial step in their development process. The Raise3D E2 has become an invaluable tool for testing the fit and finish of their gauge components. The ability to 3D print parts with exceptional precision has allowed engineers to visualize the products in person, a feat that is often challenging to achieve through digital means alone. By leveraging the large build volume and compatibility with engineering-grade filaments like ABS and carbon fiber reinforced PET, Speedhut engineers can bring their ideas to life with unparalleled accuracy.

Raise3D E2 is an invaluable tool for testing the fit and finish of their gauge components and allowed engineers to visualize the products in person.

“A lot of times, it’s nice to just print out something like a bezel or something just to show everyone else what it looks like in your hands,” Wachter said. “You know, because it’s hard to kind of convey that on the computer in a 3D environment. Everyone seems to like seeing it in person.”

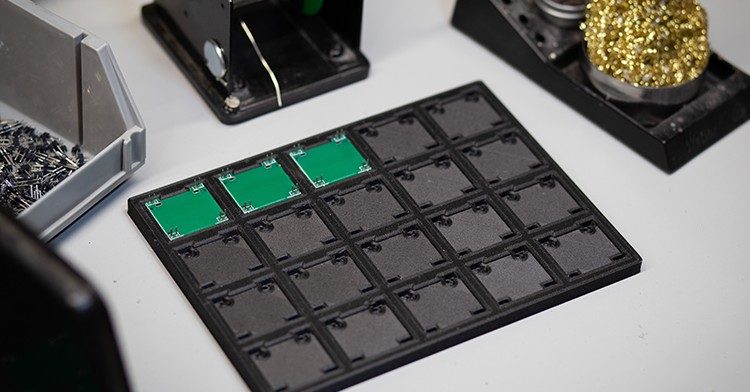

With a commitment to delivering high-quality products efficiently, Speedhut relies on Raise3D 3D printers for their production needs. The printers have proven to be durable workhorses, capable of withstanding the rigorous demands of a busy production line. The printed components, including bezels and solder fixtures, have demonstrated exceptional durability, lasting over a year without requiring replacements. The use of Raise3D’s own filament, particularly ABS, has further enhanced the durability and reliability of the produced parts.

Raise3D E2 printed components, including bezels and solder fixtures, have demonstrated exceptional durability, lasting over a year without requiring replacements.

“I was expecting to actually have to reprint a lot of jigs and fixtures every couple of months because of our production line,” he said. “Some of the tools get just so worn out because of how many gauges are going through, but they hold up great. I haven’t had to reprint any parts that we’ve had everything on the line for probably about a year now.”

Raise3D 3D printers excel in both speed and versatility. Speedhut engineers have found the printers to be fast and reliable, enabling them to meet tight deadlines and optimize production timelines. With the ability to run 24 hours a day, the printers ensure uninterrupted productivity. Furthermore, the compatibility with a wide range of filaments allows Speedhut to explore various materials, including the PET CF filament for parts requiring resistance to higher temperatures. The Raise3D printers offer the flexibility and performance needed to achieve exceptional results in diverse manufacturing scenarios.

Raise3D printers offer the flexibility and performance needed to achieve exceptional results in diverse manufacturing scenarios.

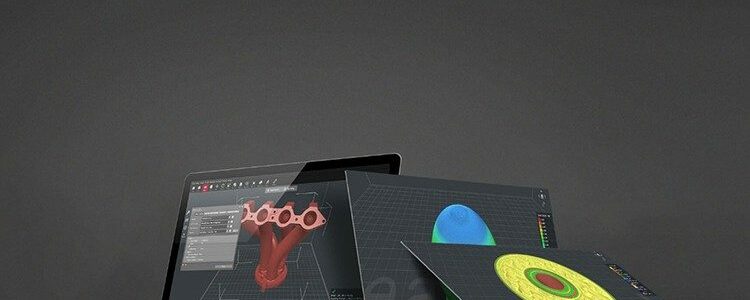

Raise3D not only provides exceptional hardware but also delivers a seamless workflow through its intuitive software, ideaMaker. The software simplifies the process of preparing and slicing prints, providing engineers at Speedhut with a user-friendly interface. With features like cloud connectivity and remote monitoring using phone cameras, ideaMaker enhances convenience and accessibility, ensuring an efficient and optimized printing experience.

“It’s a good program,” Wachter said. “I like it. Very easy to use. And I like the fact that I can use the cloud and it hooks up to my phone. Like when I’m out of the office, and I have a print going on, I can check on it with the camera, make sure it’s all good.”

IdeaMaker simplifies the process of preparing and slicing prints and provides engineers at Speedhut with a user-friendly interface.

Raise3D 3D printers have transformed the way Speedhut engineers innovate, prototype, and produce their aftermarket gauges for the automotive industry. The combination of precision, speed, durability, and compatibility with a wide range of filaments makes Raise3D printers the perfect choice for any manufacturing environment. Whether you are seeking to revolutionize your prototyping process or optimize your production line, Raise3D offers the tools you need to bring your ideas to life. Join Speedhut and numerous other industry leaders in harnessing the power of Raise3D 3D printers for unparalleled success in the automotive sector.