23/09/21

Sanitronics is an innovative company with over 20 years of experience in public toilet installations and was nominated for the most innovative SME company of 2018. Sanitronics produces custom-made, self-cleaning public toilet systems. One of these patented designs is “The Revolving Toilet”, where two toilets rotate and switch after each use. One toilet is thoroughly cleaned in the technical room, while the clean toilet is made available. This way, every visitor can experience a fully clean and dry toilet. The Revolving Toilet system was designed around issues such as vandalism, sustainability, comfort and hygiene.

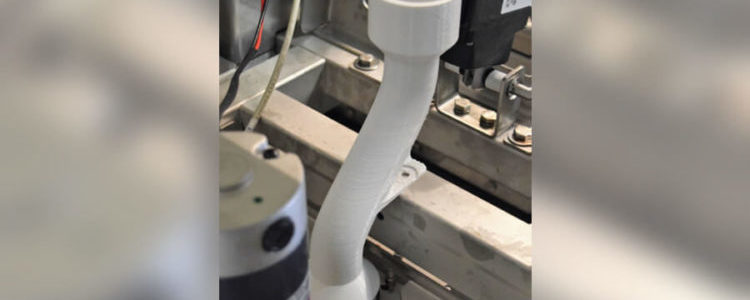

The Revolving-Toilet design requires the use of custom-made drainpipes that are watertight and long-lasting. These drainpipes are created using complicated designs with tight tolerances. For the Revolving Toilet, Sanitronics needs to be able to produce these components in-house, for a small product series.

Based on Sanitronics’ functional requirements for drainpipes, PETG filament is the best option. Sanitronics chose to use a Raise3D printer with BASF Ultrafuse PET due to its excellent layer adhesion, which can print watertight parts. After carefully calibrating printing parameters to make the most of Ultrafuse PET’s characteristics, Sanitronics acquired excellent and consistent quality from its Raise3D printer. In addition, all the necessary calibration is done using Raise3D’s 3D slicing software, ideaMaker, which provides comprehensive parameters for customization.

PETG (Polyethylene terephthalate glycol-modified) is a filament with outstanding layer bonding properties, meaning 3D printed parts will be water-tight due to the absence of layer gap exists. PETG also has excellent chemical and radiation resistance. This makes PETG a very suitable filament to printcontainer for chemicals, food and beverage, and medical uses.

The direct delivery of PETG drain pipes from a Raise3D printer is exactly what SMEs like Sanitronics are looking for. Companies like Sanitronics need fast product launches with minimal production costs to survive the initial developing stage. 3D printing’s flexible production capacity also enables Sanitronics to face market uncertainty such as consumer preference change and new user scenarios. By employing ideaMaker, Raise3D slicing software, Raise3D printers, and ideaMaker Library, SMEs will gain a strong advantage from flexible manufacturing in terms of design, material, and production.

Sanitronics’ Raise3D printers and related services are purchased from SEEDA, which is one of Raise3D’s resellers in the Netherlands.