21/10/22

The Tokyo Institute of Technology is Japan’s leading science and engineering university with a 140-year history. Among them, the Hasegawa Laboratory was established in 2008. One of its research projects is to improve the flexibility of a robot’s precision moving parts, thereby enhancing the interaction between the robot and humans (Human-Computer Interaction). Hasegawa Lab purchased the Raise3D Pro3 printer to print complex and high-precision moving structural parts, with the aim of improving the mechanical flexibility of the robot. The Raise3D Pro3 printer has proven to be the best match for producing parts that require fine surface resolution and precision.

The precision of the moving parts of robots currently on the market is insufficient, resulting in low flexibility of movement. Professor Hasegawa Shoichi once expressed his vision for the future development of robots, “I want to make a robot that can perform flexible movements. In addition, I want to reduce the cost of this technology and make it widespread.”

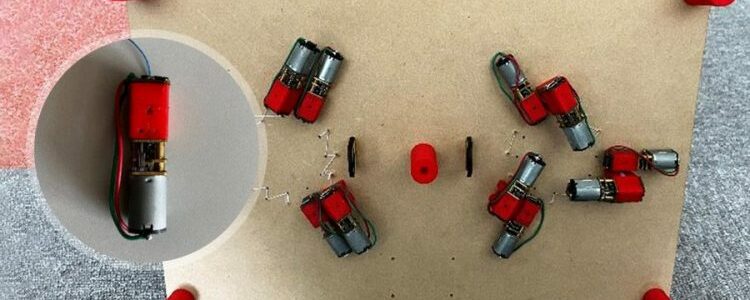

Hasegawa Laboratory added a robot structure to the inside of the plush doll. Although it has a soft appearance, the joints of the robot inside have complex and precise motion structures, such as robotic arms, bearings, and motor brackets. These parts and structures are independently designed and developed by members of the laboratory. The design and development process are more complicated. These parts are very small and have a special structure, and the number of parts required is not large. Therefore, it isn’t cost-effective to manufacture these parts using CNC technology, and engineers need to quickly review designs that are evolving every day in order to improve the mechanics of the robot. Because of copyright and confidentiality, engineers cannot outsource part fabrication to third-party companies. Therefore, this highlights the customized production advantages of 3D printers.

Part of the mechanical structure of the robot-1

Part of the mechanical structure of the robot-2

The moving parts of the robot have extremely small hole structures and protrusions, and the results show that printing these parts with the Pro3 printer still guarantees extremely high resolution and clean appearance. Professor Hasegawa Shoichi said, “After using the Raise3D Pro3 printer, the interference between the shaft and the cover has been eliminated. By installing the cover and the motor base, the installation hardness of the machine has become constant.”

When researchers at Hasegawa’s lab printed ABS parts with a 3D printer they had previously purchased, the surface resolution and accuracy of the parts were not high. Parts would be deformed due to excessive temperature, resulting in a poor fit of the mechanical structure of the robot, frequent failure of moving parts, or poor smoothness of movement. Therefore, experimenters urgently needed higher-precision 3D printers.

The printing accuracy of the Raise3D Pro3 printer is patently obvious. The improved repeatability and reliability of the Pro3 printer ensures that the printer does not misalign during travel, providing higher surface flatness and smoothness. Precise temperature control and cooling systems provide perfect overhangs; precise linear motion in all directions maintains consistent quality across all geometries, which is ideal for printing complex and small parts.

High-quality parts

The stability and ease of use of the printer are also important factors for Hasegawa Lab to have chosen the Raise3D Pro3 printer. The Raise3D Pro3 printer can maintain uninterrupted printing 24/7, even in emergencies, such as power outages, running out of filaments, overheating interruptions, maintenance and repairs, etc. At present, there are 25 researchers in Hasegawa Laboratory. After using the Raise3D Pro3 printer, and the labor force has been greatly freed up while researchers now have more time and energy. Pro3 printer can be easily operated by inexperienced researchers without any prior training. The designer only needs to prepare the CAD file of the desired part, import it into ideaMaker – Raise3D’s slicing software -, slice it, and send it to the printer to print.

Mechanical structure printed with the Pro3 printer

The introduction of the Raise3D Pro3 printer will greatly stimulate the laboratory staff’s interest in research. The researchers currently use PLA filament to make models of robust parts due of the strong bonds between the layers. Researchers will use ABS or other filaments later on to increase strength and improve other properties of the part. The Raise3D Pro3 printer will become the innovative research solution of Hasegawa Laboratory, thereby helping to fulfil the laboratory’s potential in the field of human-computer interaction.