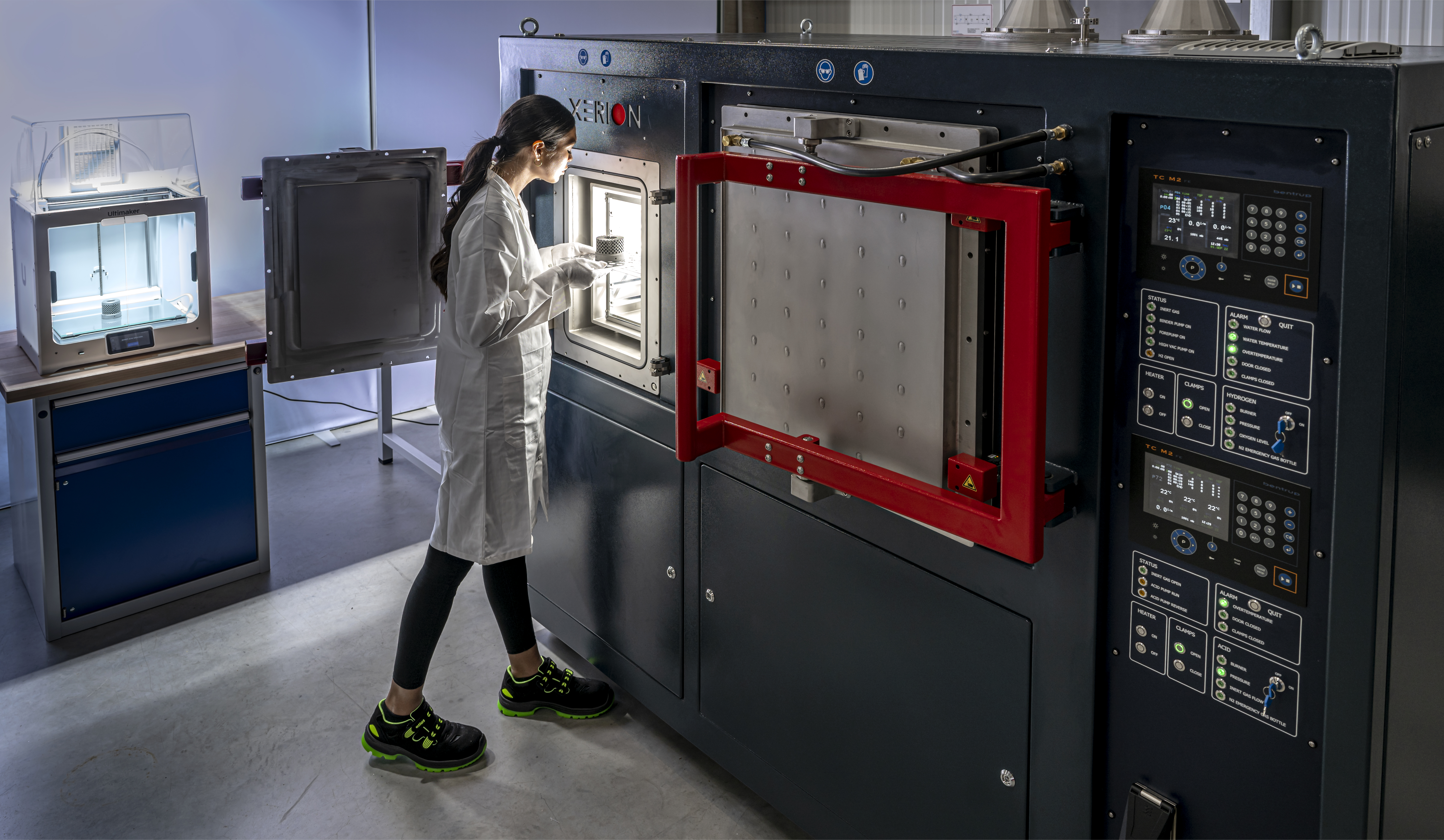

Fusion Factory XS

With over 20 years of experience in its market, Xerion has a perfect understanding of the issues of insulation, temperature and safety of furnaces, making it a partner of excellence in terms of quality and efficiency.

The Fusion Factory XS is a turnkey additive manufacturing solution for metal and ceramic parts. It integrates all technological steps in a single system:

- The 3D printer

- The catalytic debinding unit, which operates under nitrogen and acid gas

- The sintering furnace, which heats up to 1550°C under different atmospheres: nitrogen, hydrogen, vacuum, air.

This is the latest member of the Fusion Factory family, the new ultra-compact version for mobile, demanding and versatile use outside the supply chain.

All three units are securely mounted in rugged PELICAN CLASSIC 19″ TM 21U racks.

Known to be the most robust and intelligent transport systems on the market, their outer shells withstand any impact in any environment.

As a result, necessary spare parts no longer have to be manufactured in a factory and transported to the point of use; instead, production is done directly on site and components can be manufactured at any time.

Additive manufacturing based on filaments is particularly suitable for use in harsh conditions, as there is no conditions, as there are no powder problems or laser radiation.

The metal or ceramic powder incorporated in the the filament is 100% in the finished part, which represents a very good efficiency and durability.

Why use ovens in additive manufacturing ?

Today, processes based on metal or ceramic filled filaments and binder jetting are in full expansion. These processes require three steps before obtaining the final parts: printing, debinding and sintering. Once the printing stage is completed, it is almost always necessary to debind the part, before finally sintering it to increase its mechanical characteristics. Depending on the type of binder present in the material, there are several types of debinding:

- Debinding in a solvent, for example in an acetone bath for organic binders

- Catalytic debinding for BASF Ultrafuse materials.

Xerion’s Fusion Factory range offers products adapted to both types of debinding. For sintering, their expertise is even broader, it is possible to sinter almost all metals and ceramics from 3D printing processes.

It is important to note that these two post-treatment steps are critical and condition the density and final quality of the part. Xerion debinding and sintering furnaces not only ensure this quality, but also safety and efficiency unmatched on the market.

FR

FR