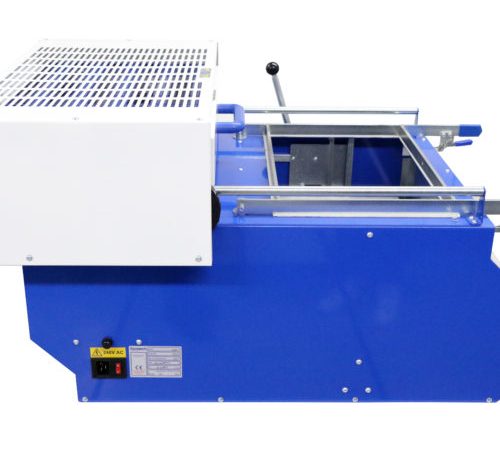

Thermoforming 450DT

430 x 280 x 160 manual thermoformer with 4 “touch screen and programmable logic control system that can store up to 20 programs.

Formech continues to bring the latest technology and functionality to a wider range of thermoformers.

The new 450DT (now replacing the 300XQ) is equipped with a programmable logic control (PLC) system. The graphics and icons allow a quick and easy use of the machine. The 450DT can save up to 20 thermoforming programs which allows the user to quickly load existing projects. The new 450DT offers students, designers and inventors an answer to the demands of the industry.

CHARACTERISTICS

4 “TOUCH SCREEN WITH MEMORY FUNCTION

Mitsubishi 4 “Touch Screen with up to 20 programs.

QUARTZ HEATER WITH STANDBY VARIABLE

Quartz heaters heat very quickly and save time and energy.

4 CONTROLLED HEATING ZONES INDEPENDENTLY

Four Quartz heating zones that provide warmth quickly and thermoform demanding shapes and materials.

EMPTY & DISMANTLING

Once the formed portion cools, air is injected between the mold and the plastic to release the molding.

GAUGE

A visual indication of the applied vacuum (pressure in Hg / bar).

FR

FR