DeskProto is aimed at designers for Rapid Prototyping, at jewelers for wax models, artists for

sculptures, medics for prostheses, moldmakers, woodworkers, teachers, students, hobbyists, etc…

DeskProto is fast, it’s lowcost and it’s very easy to work with.

DeskProto Version 7.0

(March 2018) The new DeskProto Version 7.0 contains many improvements and new features.

Two of these changes stand out

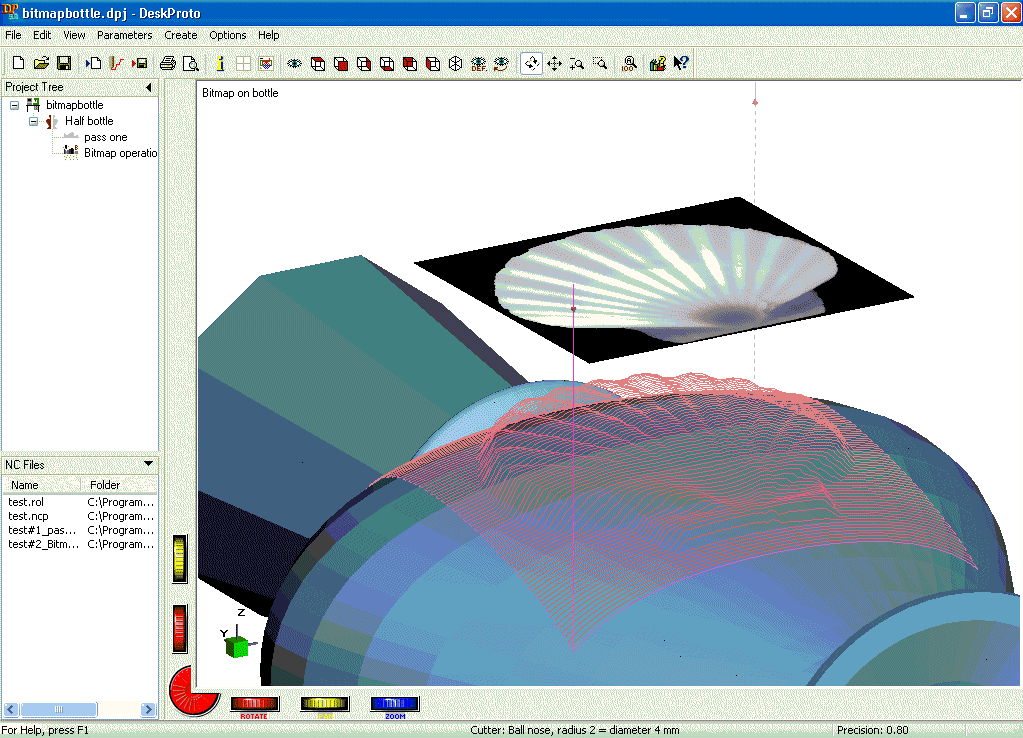

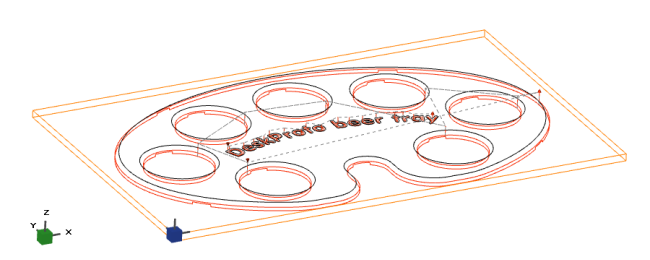

Just as the other edtions it offers all three types of CAM: Vector machining (2D DXF files), Geometry machining(3D STL files) and Relief machining (any bitmap image file). For all these Operation types the basic functionality is present, so you can complete real jobs.

Description

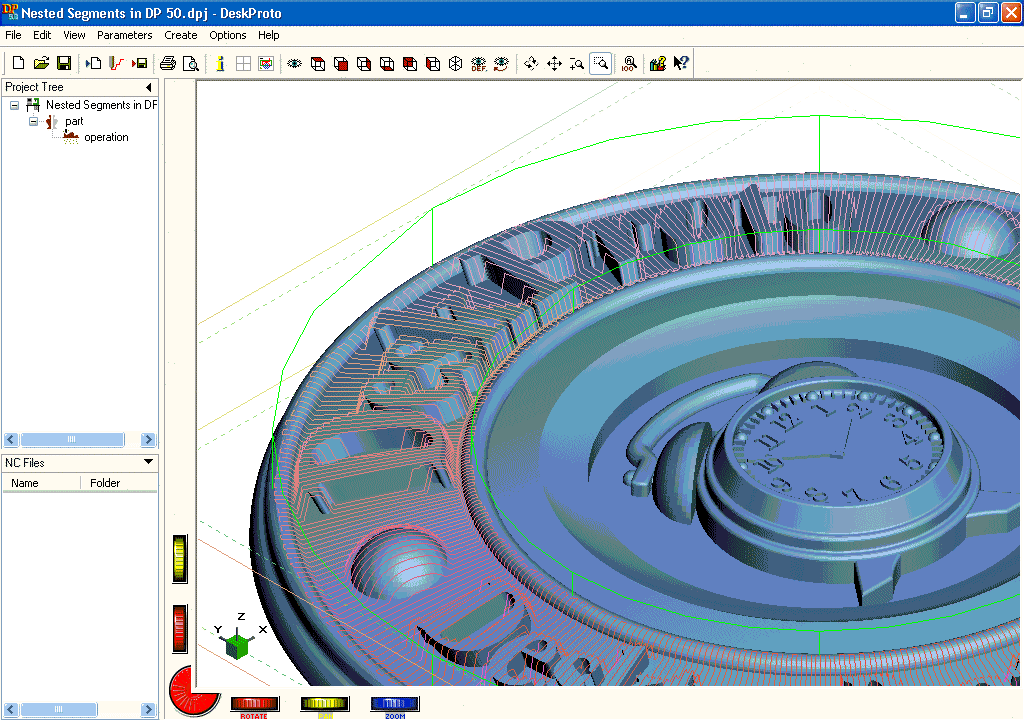

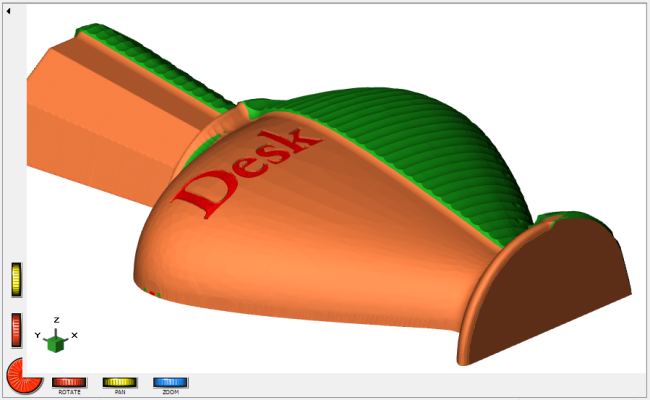

DeskProto have been developed to offer CAM (Computer Aided Manufacturing) to users with a different (non-CAM) profession. Like a designer needing a prototype, a jeweler needing a wax-model, a medic needing a brace, etc. DeskProto will quickly calculate toolpaths to be sent to a CNC milling machine. It’s key feature is ease-of-use, even for the most complex geometry. Novice users follow the wizard interface, experienced users can also directly change any setting (dual user interface).

How does it work

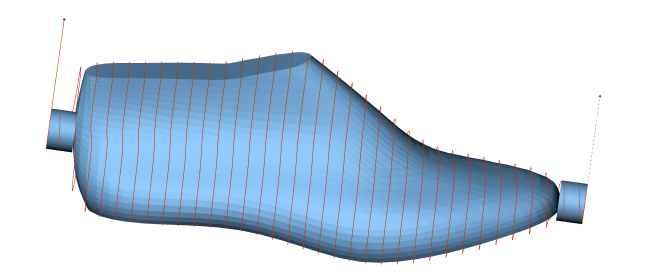

Starting point for DeskProto is an STL-file (3D). This file type is standard for all types of 3D Printing, and contains a geometry-description in the form of small triangles. Any current 3D CAD-system is able to write this type of file. For 2D both DXF-files end EPS/AI file can be imported, and for bitmap most formats are supported.

DeskProto reads the file and displays its contents. At this point it is possible to scale the geometry, translate, rotate etc. After entering some milling parameters (type of cutting tool, required accuracy, etc) DeskProto will calculate the milling paths. No danger for damaging the model: guaranteed gouge-free ! Send the path information to the desktop NC milling machine in your own office, and you will have your prototype ready: within a few hours !

DeskProto combines well with any 3D CAD software, and with any CNC milling machine.

Application areas

Current users show a wide variety of applications, including:

- Industrial designers

- Jewelers

- Woodworkers

- Medical professionals

- Schools

- Hobbyists

FR

FR