SBI and plasma welding

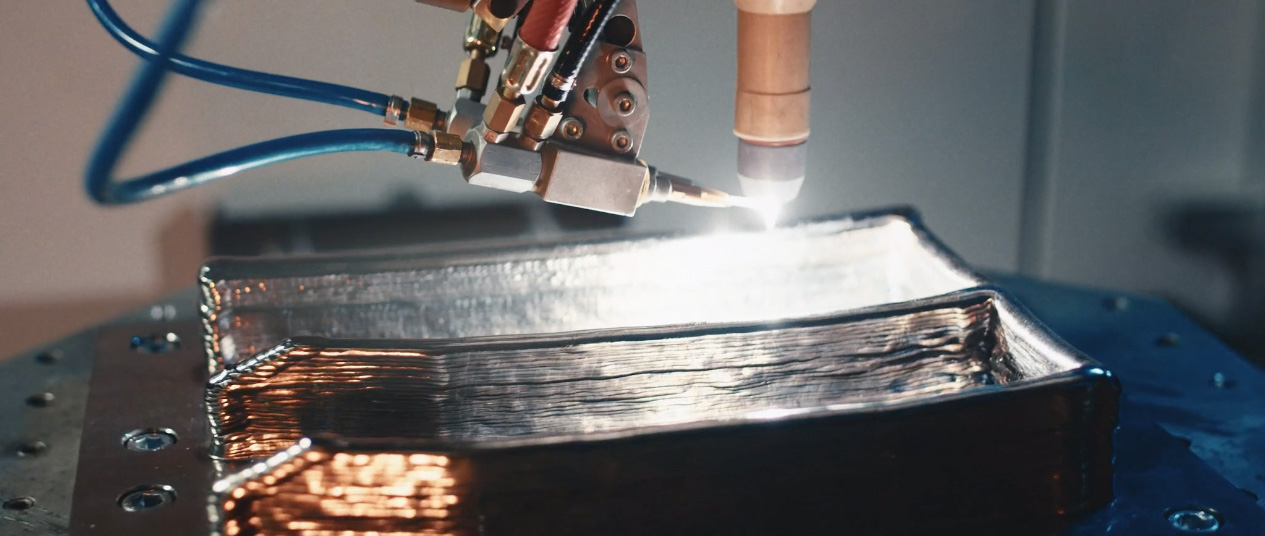

SBI was founded in 1999 and has been working with plasma welding since its inception. Automated solutions for the repair of forging dies, coatings and plasma arc deposition machines have been developed. This experience is now being put to use in a range of additive manufacturing machines, which have been on the market since 2019. The plasma-based technology is called PAAM (Plasma Arc Additive Manufacturing).

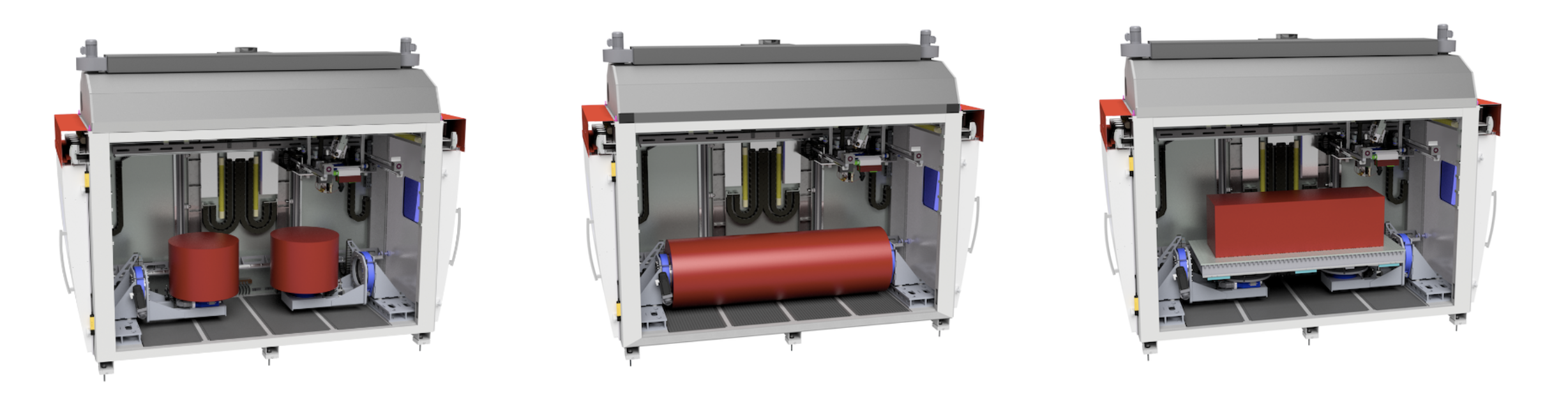

The M3DP machine

SBI offers 2 machines including the M3DP (Metal 3D Printer). The M3DP is a modular machine with 2 configurations available for printing. The build chamber can be inerted to print metals at high temperatures to limit unwanted reactions. The material can be supplied in powder or wire form, or even both to create alloys in situ. The use of plasma as an energy source allows for some of the highest deposition rates in metal additive manufacturing, reaching 10 kg/hr.

Benefits of the technology

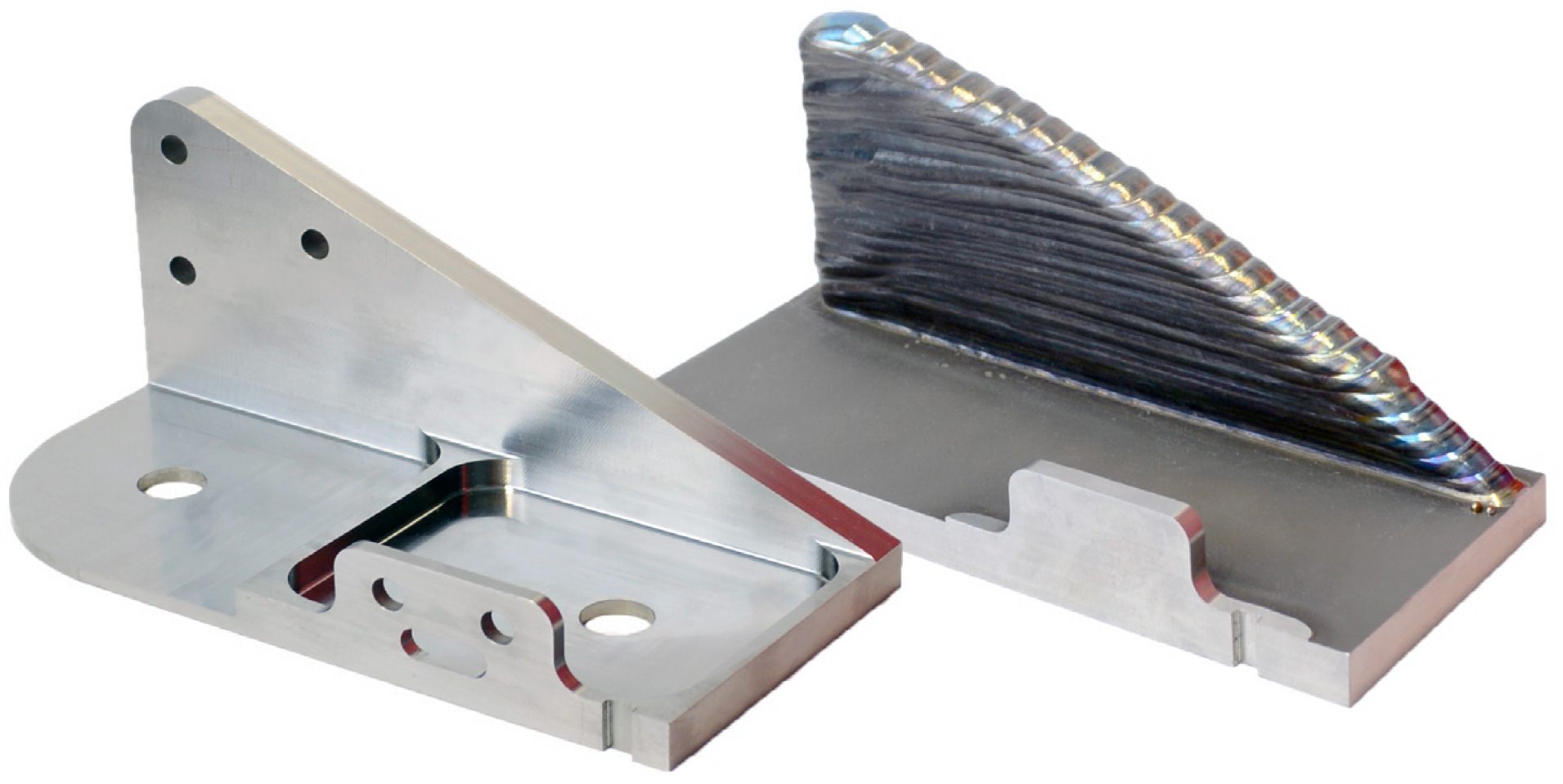

In addition to its impressive deposition rate, the Near Net Shape technology has an advantage in terms of economy. The parts produced must be machined after printing (milling, turning, etc.) but to a much lesser degree than machining from a solid substrate (i.e. block, billet, etc.). The labour involved in this post-processing is less expensive than in traditional processes. Any material, which can be joined by fusion welding, can be processed by the M3DP. Materials such as titanium, nickel-based alloys, high-alloy steels and aluminium are of great interest because of their high savings potential.

A complete solution

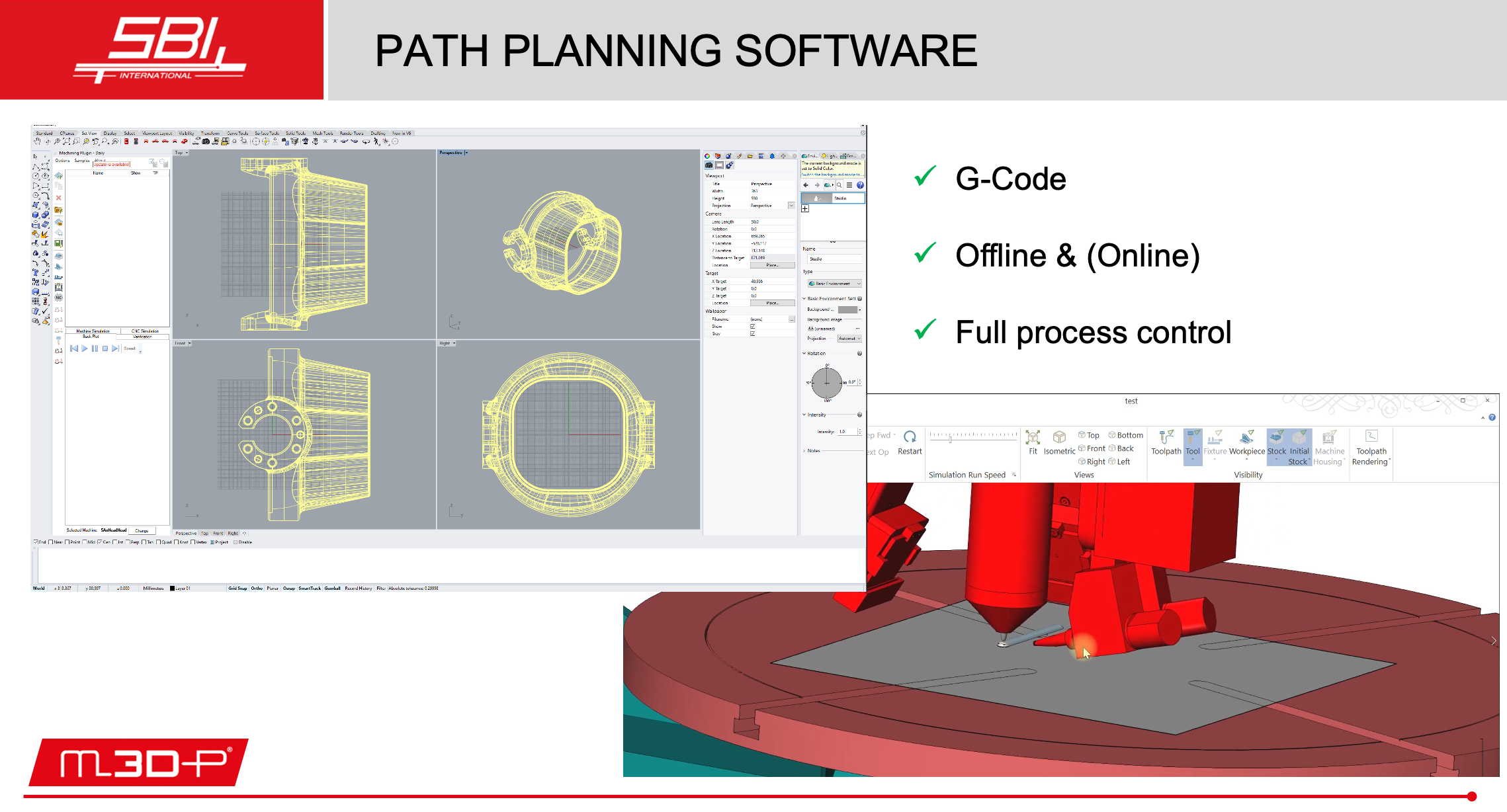

The machines are supplied with specific software for additive manufacturing with SBI machines, which allows for optimal management of the construction. The slicer is used to generate the tool path and the associated welding parameters.

A wide range of accessories facilitate the process and optimise the parameters, leading to a successful construction. For example, cameras for monitoring during the manufacturing process are available. By linking the design parameters to the presence of defects, it is possible to carry out parametric searches.

FR

FR