STANDARD FEATURES

- CNC OSAI : 10/510

- Spindle : 10/12 kW 24.000 tpm, HSK F 63, a

- Axis rotations : A +/- 120° ; C +/- 360° (30 tpm)

- Changeur tools : linéaire, 8 positions

- Table of work -: 300×300, M8

- Control screen

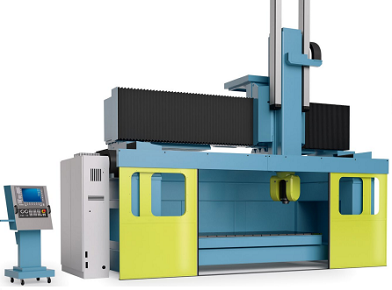

- Carter Machine, 2 doors controled by CN

- Work table : 1600 x 1540 mm

- Course X : 1820 mm

- Course Y : 1600 mm

- Course Z : 900 mm

Conditions générales de ventes

- machine loaded on truck, ex works

- start-up Europe / 5 open days (travel expenses not included)

- Multistation service, 12 months or 2000 hours warranty

T-SERIES – OVERHEAD CRANE > LONGITUDINAL CRANE

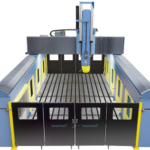

Multiax has developed this 5-axis machining center model for fast and accurate machining of complex 3D surfaces that are typically used in the plastics and composites industry.

The Model T is productive, reliable and easy to operate. It is designed to exceed customer expectations. This is possible due to the rigid frame and construction of the mechanical elements that allow for greater axis perpendicularity, speed and positioning accuracy. The mechanical structure was tested with finite element analysis software by simulating high stress operating conditions and heavy use, as well as to check the strength of the base.

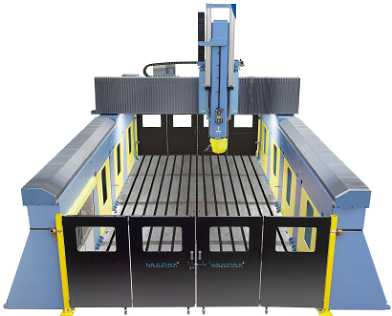

A-SERIES – OVERHEAD CRANE > SUSPENSION CRANE

The 5-axis, suspension bridge CNC machining center is ideal for machining large parts. Common automated CNC operations include milling, cutting, drilling, rivet and fastener applications, etc. The moving bridge structure with a wide range of optional components, allows the user to machine various sizes of large parts, while ensuring high cutting speeds, high accuracy and a smooth surface finish.

K-SERIES- HIGH MOBILE CROSSBAR > HIGH RIGIDITY LONGITUDINAL CROSSBAR

The machine, rigorously analyzed by FEM, is made of a steel structure, welded and reinforced, which ensures the dimensional stability and rigidity necessary for heavy operations.

Thanks to its modular design, it allows to choose among several versions with different types of rails and different quantities of carriages.

FR

FR