Robust

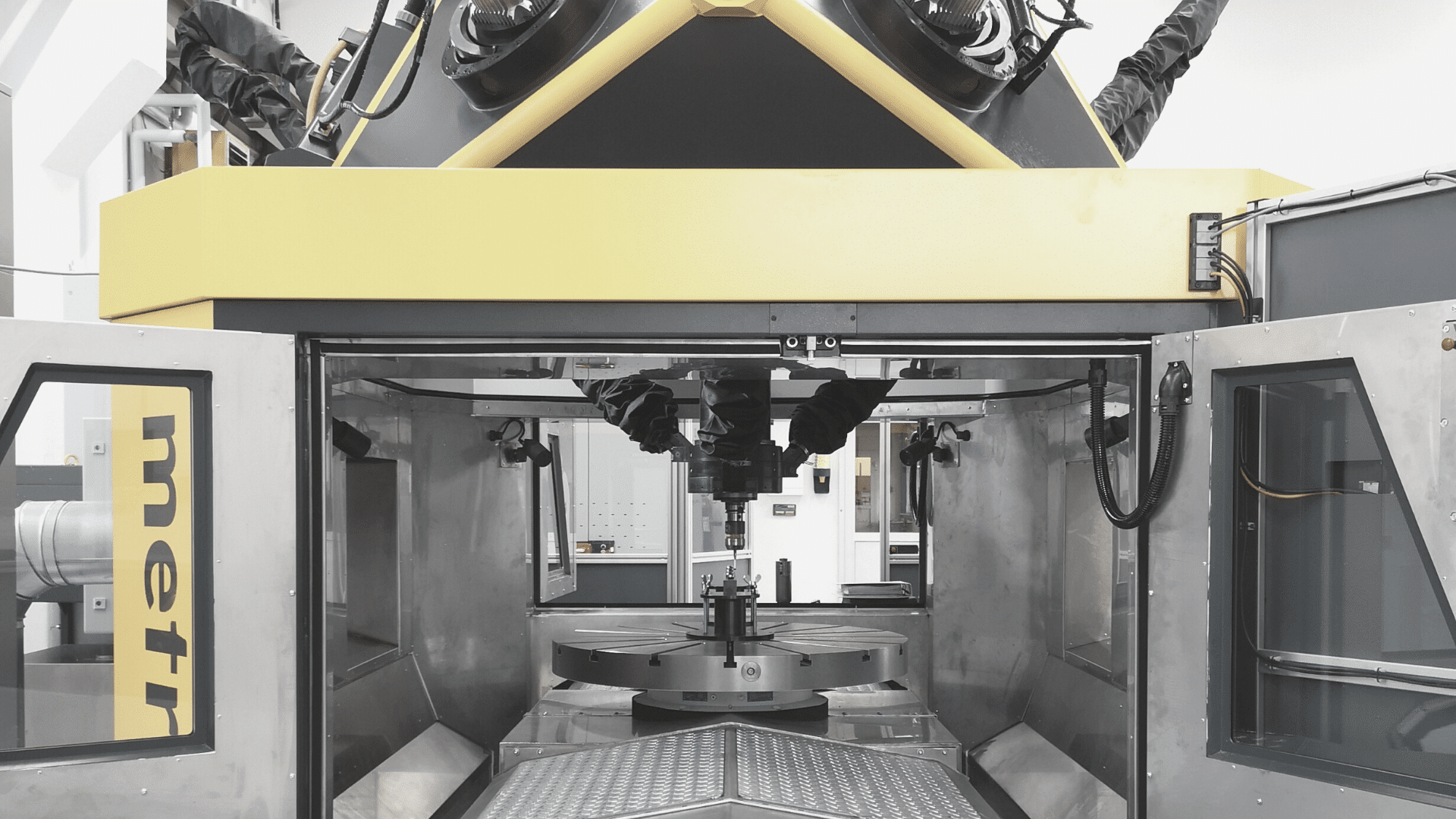

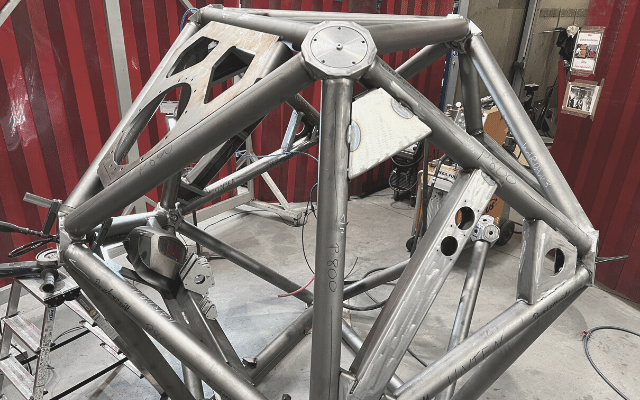

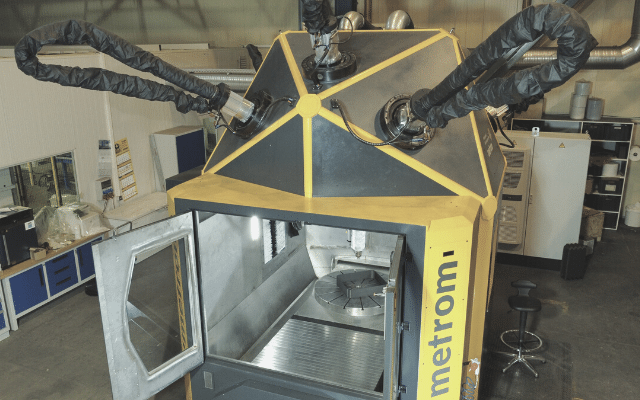

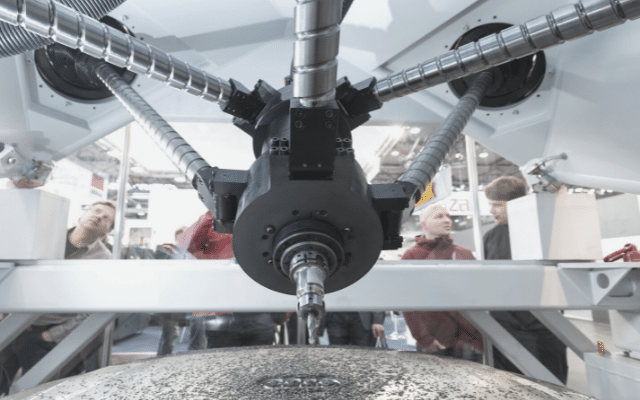

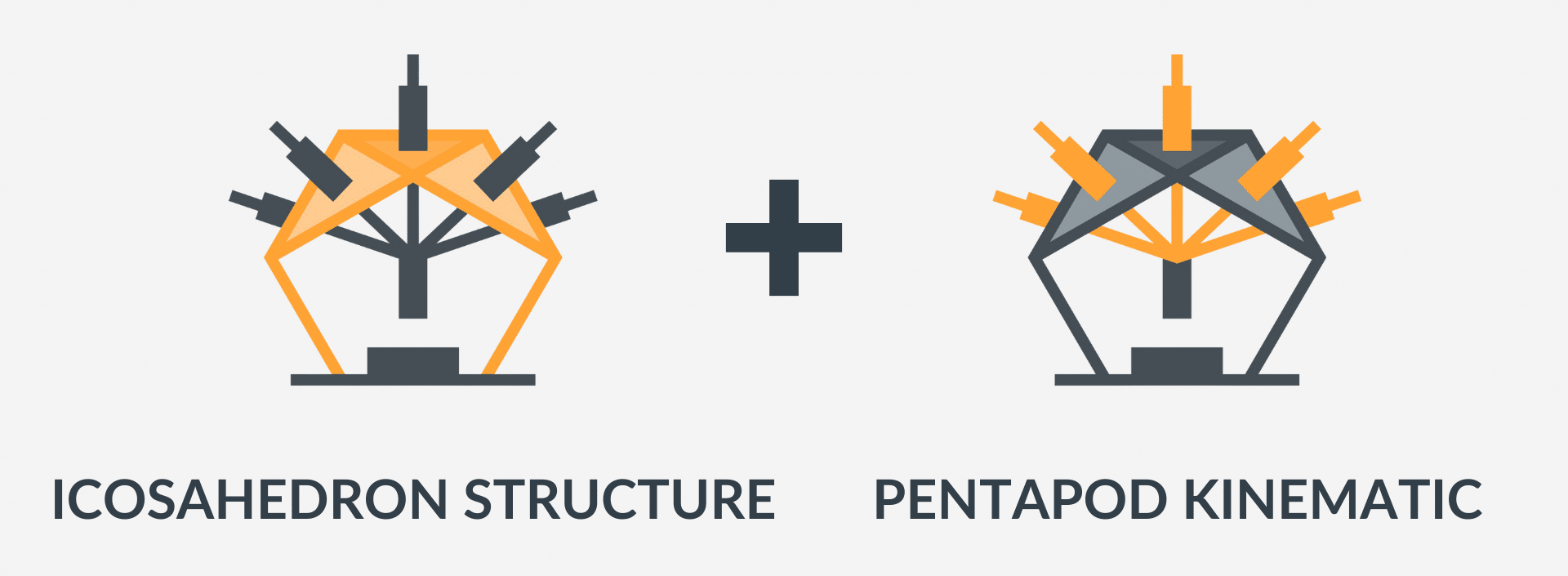

As a physical body, the icosahedron has the highest inherent rigidity. This advantage is exploited here, so that high rigidity of the machine is provided without a machine foundation, thus enabling high machining accuracy. The combination of the icosahedron and the 5 struts kinematics (Pentapod) is an optimal solution for a robust and durable machine tool.

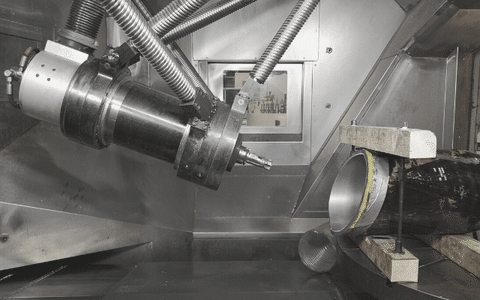

High precision CNC machining

The P-series does not require a special foundation to be installed. The icosahedral structure of the machine cover with the five ball screws is a tube construction. Water is constantly pumped and circulated through the tubes and the five spacers, which keeps the enclosure at a constant temperature to counteract outside temperature fluctuations and ultimately allows for high machining accuracy.

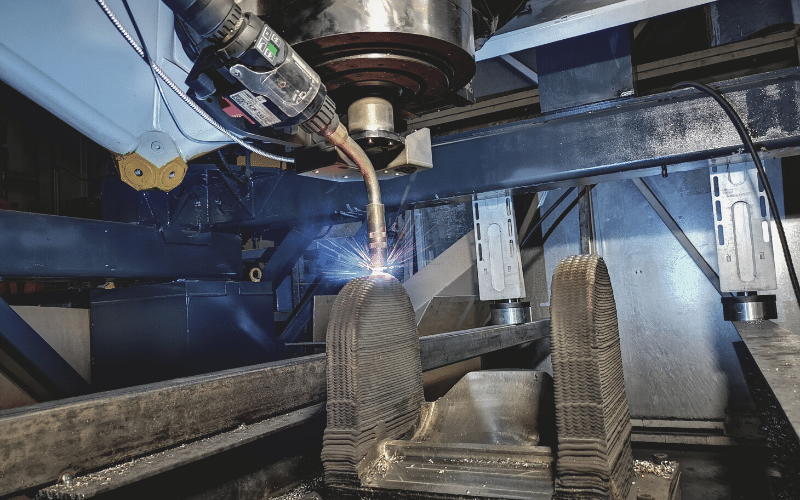

Hybrid machines

METROM Machines are design to us additive manufacturing in your process. These machines are designed to use recharging on existing parts and also machining every size and shape product. This allows to process machining (milling and drilling) between two building phases.

FR

FR