HAMUEL HSTM 1000 HYBRID MACHINE

- Excellent up-time

- High static and dynamic rigidity

- Thermo-stability in all axes

- Modular construction

- Ergonomic design

- Motor spindles with high speed and strong torque

- Utmost machine dynamics for a short component machining time

- Best accessibility for maintenance and service

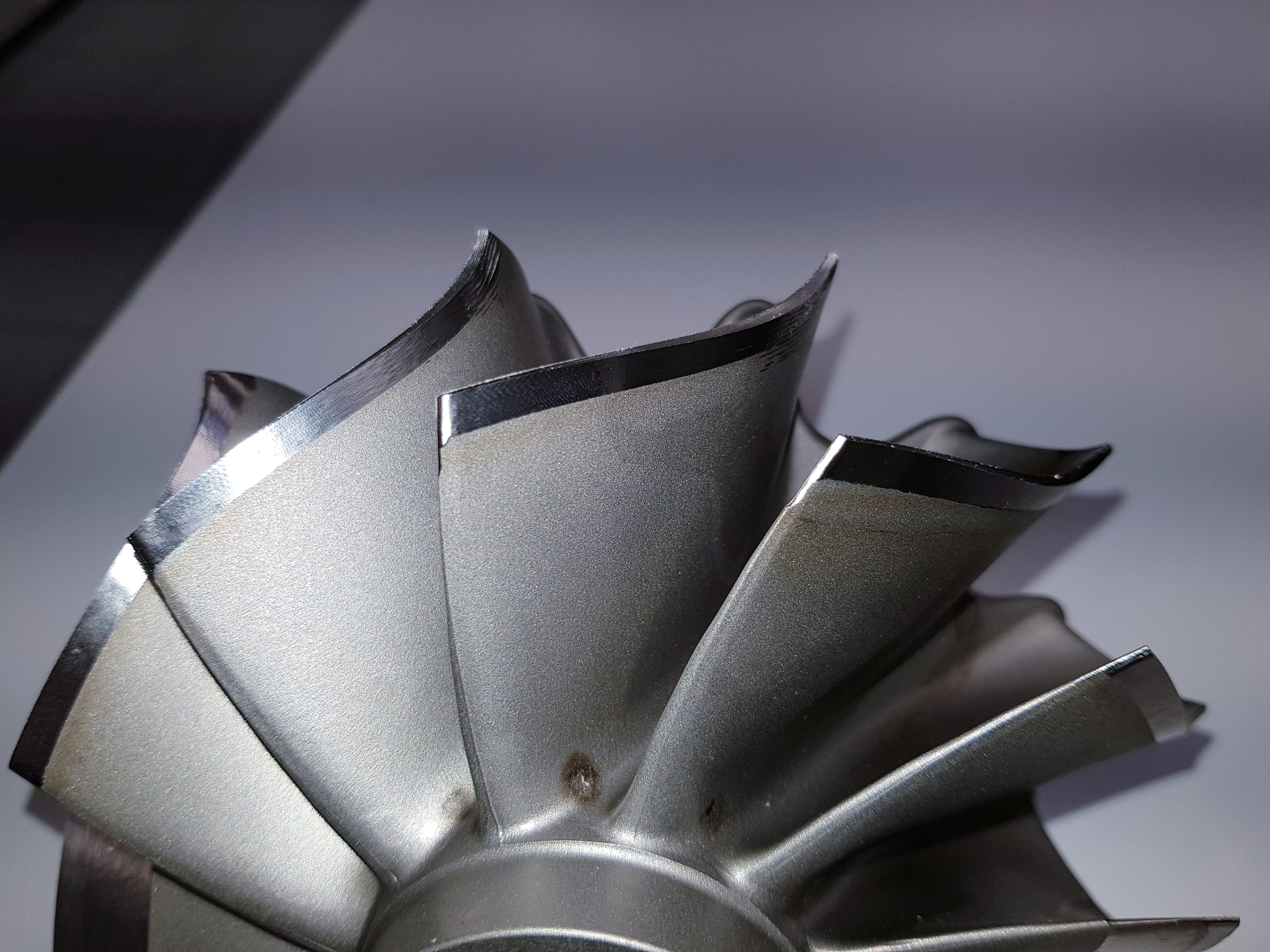

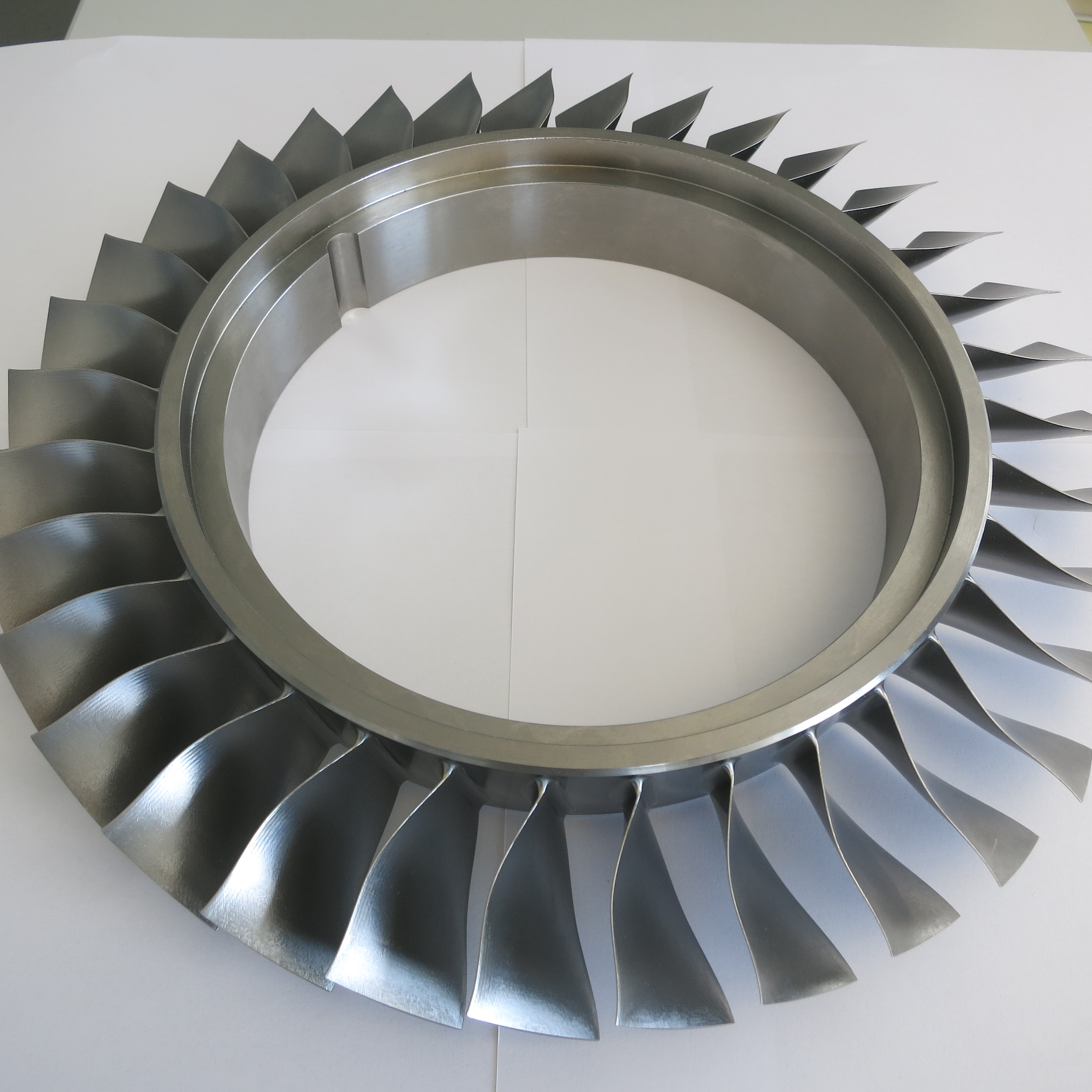

- Highest demands regarding accuracy and surface quality

- Automatic changing of tools and components

- Excellent surface qualities owing to hydrostatic A- and C-axes

Precision and economics

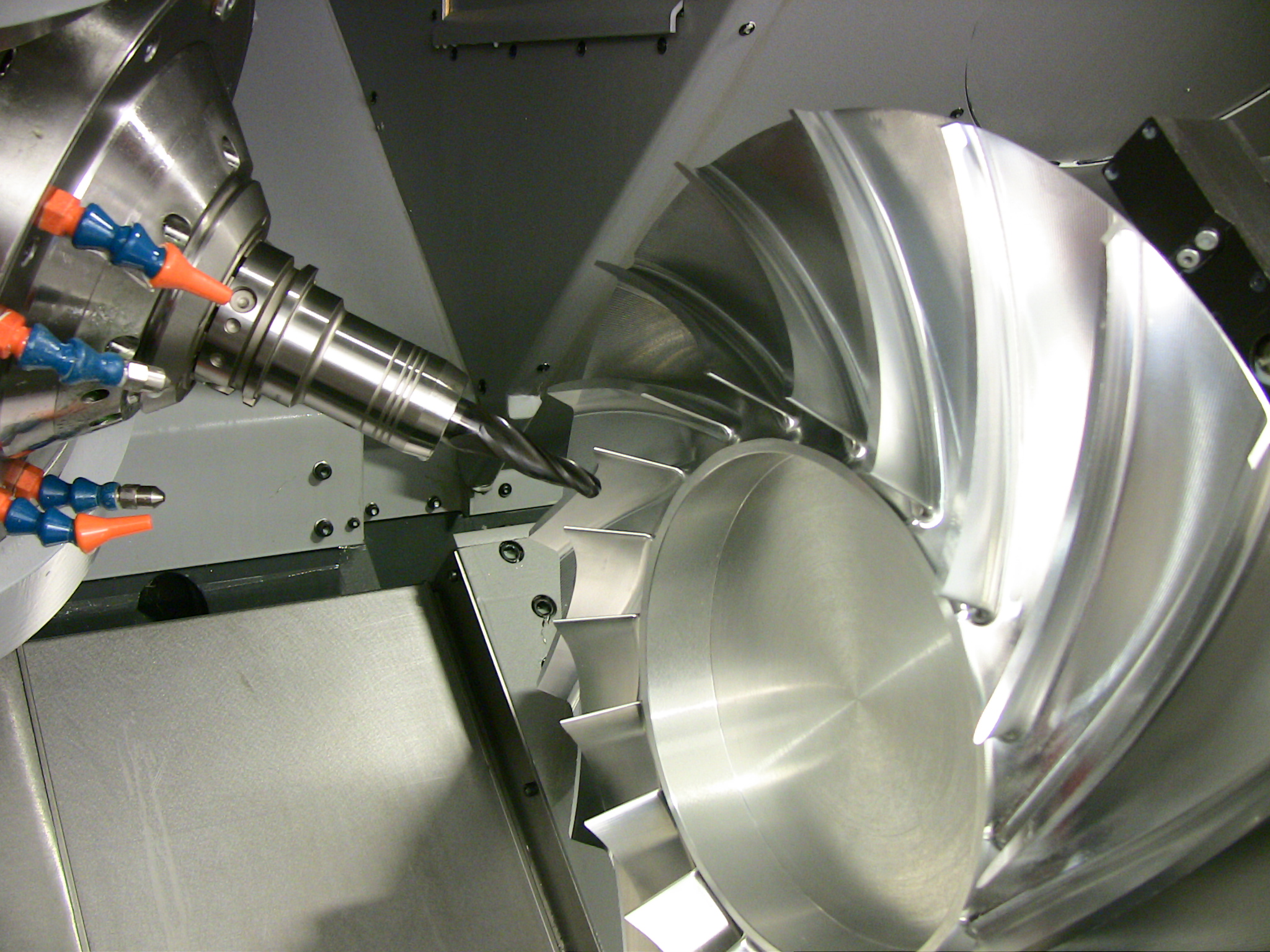

Where the attainable accuracies and surface qualities are concerned, the HSTM even exceeds the highest demands for modern blade machining. Continuous maximum productivity is ensured by its sturdiness and rigidity, as well as by the integration of an HSC-support.

Extreme adaptability

The compact construction of the machine permits a rapid and flexible installation at the customer plant – without any special requirements as to the nature of the floor foundation. The machine consists of a one-piece base, where all units have been arranged in an ideal way for the machining of horizontally clamped components.

Ergonomics and productivity

The inclined position of the axes in the machining area guarantees an excellent chip removal. Standard interfaces at the rotary axes and peripheral components are the essential characteristics of this machine, being designed for utmost productivity. In arranging the operating and service elements, special importance was attached to their ergonomic layout.

FR

FR