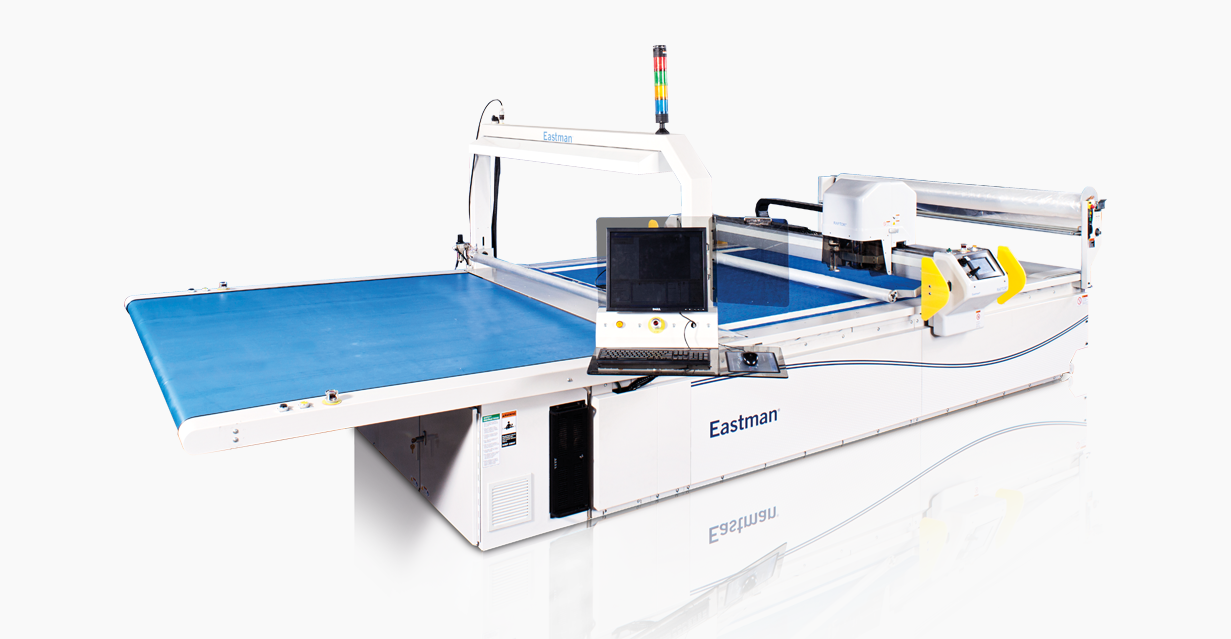

Raptor 75x

Quick-connect, modular design for productivity

Eastman RaptorTM models have been uniquely crafted in the USA to automatically pull stacked material plies from the spreading table to a modular, bristle-block conveyor bed for reciprocating knife cutting of patterns. Featuring precise system operations and driven by state-of-the-art motion control communications, the Raptor is an industrial-strength solution for low- to high-ply cutting of flexible material goods. Eastman’s exclusive IntellicutTM knife control software increases the accuracy and integrity of the cut from top to bottom ply. Eastman’s comprehensive range of equipment, from front-end preparation through the cutting phase, are an integral part of composite, technical textile and apparel factories around the world.

Heavy-Duty

The RaptorTM frame is made of heavy-gauge welded steel and is engineered to withstand challenging mass production environments. Eastman’s exclusive tool head design allows for a short and rigid reciprocating blade which ensures less deflection when cutting heavy-loads of stacked material goods — a recipe for accurately cut pattern pieces from top-to-bottom ply.

Modular Design

All components of the tool head are modular making it easily accessible for maintenance and replacement of internal components and consumable items. Quick disconnect plugs further simplify the process. The frame design is also modular; custom widths and lengths are available. Maximize your production and minimize maintenance time !

Real-time diagnostics for immediate support

Systems that are networked may be accessed by Eastman technicians off-site in real-time for immediate troubleshooting and support. Realtime diagnostics monitor all wires and signals, as well as motors.

Software

The Raptor’s operating control software is all-inclusive with your purchase. The intelligence behind advanced operations and algorithms will become an integral part of your daily operations. The software features proactive reporting on blade-wear and usage. It also has user-controlled settings for knife control, vacuum power and blade sharpening. Control settings manage user levels.

Strength

The RaptorTM has been engineered to handle heavy-ounce materials like denim, high tenacity synthetics and complex fiber blends, alongside the finest silks and lightweight fabrics. Cut multiple plies at once, shown at left.

Environmental

A variable frequency drive control with Eastman’s high-efficiency vacuum provides consistent material compression for the entire job while reducing power consumption.

Features

The Raptor™ Tool Head, patent pending

- Quick change knife and sharpening discs

- Reciprocating knife provides precise vertical stroke cutting

- IntellicutTM knife control software ensures quality cuts from top to bottom ply

- Cutting up to 3 in. (7.5 cm) of compressed material

- Low pressure, light-touch sharpening unit. Sharpening can be adjusted to user defined angle. Utilizes magnets to maintain even pressure of the sharpening discs against the knife edge ensuring the sharpest blade

- High-speed-single or dual pneumatic drills for punching

- Air chillers direct air flow onto the blade for maximum cooling efficiency

- Easy access to knife system and assembly parts simplifies daily maintenance procedures

- Blade wear monitor

- Control of corners to minimize fusing

Other Features

- Materials database

- Management reporting

- Software-controlled vacuum settings

- Easy to replace, the bristle blocks used in the cutting area snap-in and snap-out individually

- Blast gate reduces time in advancing material

- Optional overhead light maximizes visual inspection of parts

Safety

- Six remote emergency stops: two on cutting gantry, four system-mounted

- Additional gantry-mounted stop disks pause system operation until returned to neutral and reset. Operation can then be resumed from any position

- Tool head is equipped with plexiglass safety window to keep hands free of potential knife injury during operation

- Single turn-off point with a universal power system for lockout/tagout safeguards employees from unexpected start-up

- Stack light indicator marks operation status

Options

- Knife Chiller | Direct knife cooling improves cutting speeds and the ability to cut heavier-ounce materials

- Lateral drive | Motorized device for moving the system from one spreading table to another

- Automatic bristle cleaner | No separate cleaning cycle

- Resealer | Reseals the area that is cut to generate better vacuum hold-down so that material does not shift while being cut.

- Heavy-Duty Knife | Less blade deflection for tough materials

FR

FR