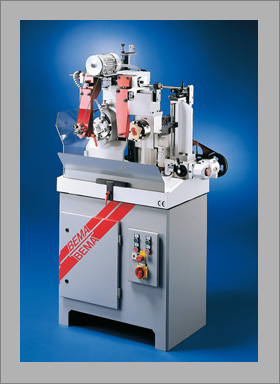

Outstanding features of the BEMA System 3500 engraving machine

- an engraving machine which is easy to operate and handle

- reduction range of 1:1.41 to 1:100

- no relief adjustment because of exact positioning of the pivot on the stamp surface

- enlargement

- 1:1 or additional device without anti-clockwise adjustment

- continuous feed

- feed and speed change possible during the machining operation

- automatic speed regulation of tool and model

- almost immovable mass because of weight reduction during scanning process, using special aluminium from aeronautical engineering industry

- controlled feeler arm through the use of double rollers

- X/Y axis for precise adjustment of the reduction range

- 2 adjusting microscopes for precise setting of milling cutter and callipers

- Machine completely equipped with halogen machine light, high frequency inverter and motor milling spindle.

1. The specification

Your model can be made of plaster, steel, bronze or Duroplast. Of course, you can have a model made from wax and then develop a Duroplast model by means of an intermediate mould. The maximal model diameter is 250mm.

2. The tracer pin

The tracer pin scans the model. Since the machine operates without vibrating, even the slightest depressions are picked up.

3. The milling spindle

The milling spindle is firmly connected to the tracer pin and mills precisely what is scanned on the model. There is no need to supervise the complete scanning and milling process. The machine functions totally automatically, round the clock.

4. The stamping die

With geometric precision, the die can be engraved exactly or reversed. The material is tooling st

BEMA System 3500 including standard accessories

- precision/engraving spindle

- Ø 40 x 140, 16,000 rpm, maintenance-free with Ø 6 mm chuck

- Ø 6 mm engraver’s milling cutter in hard metal

- 17° VHM callipers

- Ø 320mm flanged chuck

- 2 x Ø 125 mm three-jaw chucks

- support plate weights

BEMA System 3500 Technical data

- 1:1 copy milling for max. 250mm workpiece/model diameter

- mirror transfer (Janus mould)

- automatic speed regulation of tool and model

- continuous feed

FR

FR