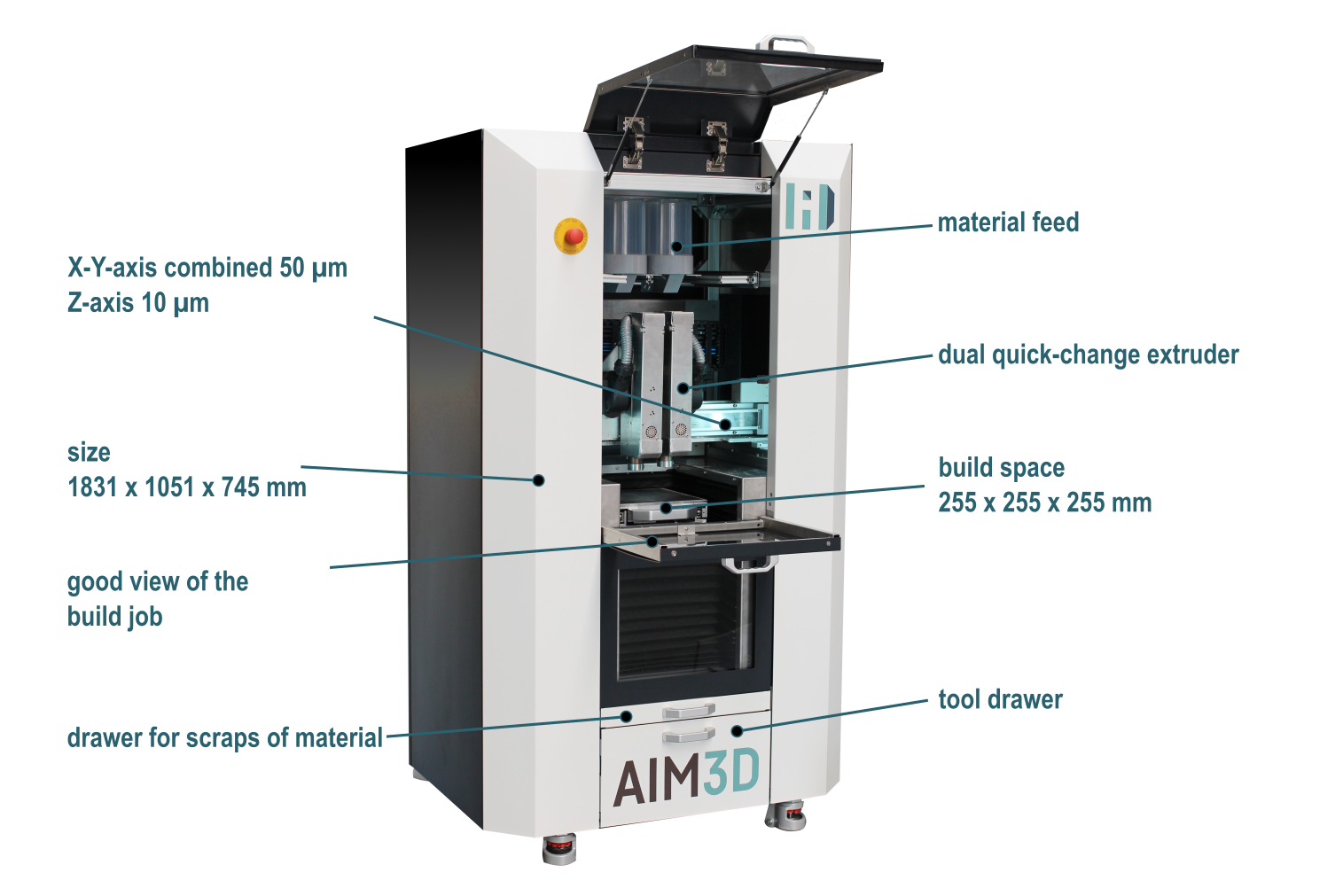

AIM3D – ExAM 255

The ExAM 255 by AIM3D is a groundbreaking 3D printer that sets itself apart with its exceptional use of MIM-Pellets (Metal Injection Molding) as feedstock. This unique feature allows the printer to work with a wide range of materials, including metals, polymers, ceramics, and composites, making it a versatile choice for numerous industries.

By employing MIM-Pellets, the ExAM 255 achieves significant cost savings compared to traditional 3D printing filaments, without compromising on quality. Its high precision and advanced calibration systems ensure the production of intricate and accurate components.

The printer’s large build volume further enhances its capabilities, enabling the creation of complex and sizable parts in a single print, reducing assembly requirements, and saving valuable time.

With its user-friendly interface, the ExAM 255 simplifies the printing process, making it accessible to both experts and beginners alike.

The ExAM 255 finds extensive applications across aerospace, automotive, healthcare, tooling, jewellery, and architectural industries, providing on-demand manufacturing solutions, reducing material waste, and offering design flexibility.

In conclusion, the ExAM 255 redefines additive manufacturing, offering unique technical refinements with its MIM-Pellet usage. Embrace the future of manufacturing with the ExAM 255 and unlock a world of endless possibilities for your business.

FR

FR