Multi-material 3D printer

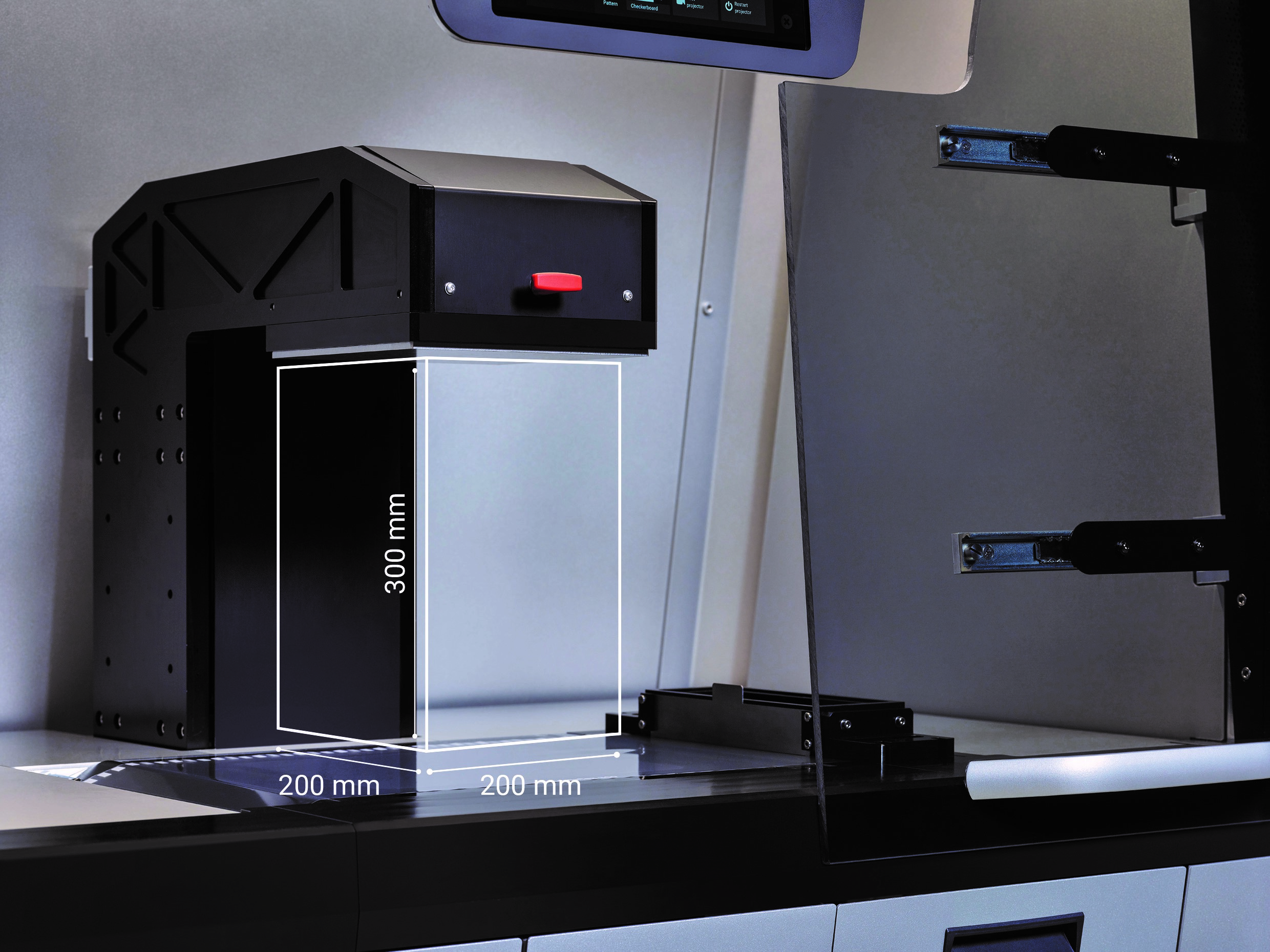

Large build volume

The Admaflex 300 has an extremely stable machine concept for production, capable of handling feedstocks with a broad range of viscosities. The printer is available with build volumes up to 260x220x500 mm. It is designed to meet the demands of customers using the Admaflex Technology for example for investment casting applications.

Patented feedstock system

The Admaflex 300 has an integrated high-volume material handling system with automatic vision controlled dosing to enable 3D printing of large components. It is designed to effectively handle materials with high viscosity, normally associated with ceramic slurries, enabling high reliability and speeds for continuous high-throughput and high volume production. This innovative system also enables efficient feedstock management by reusing the excess material.

Benefits

- Produce large components

- A clean workplace and no material waste

- Quick and easy material switch

- High throughput

- The ability to process multi-material prints

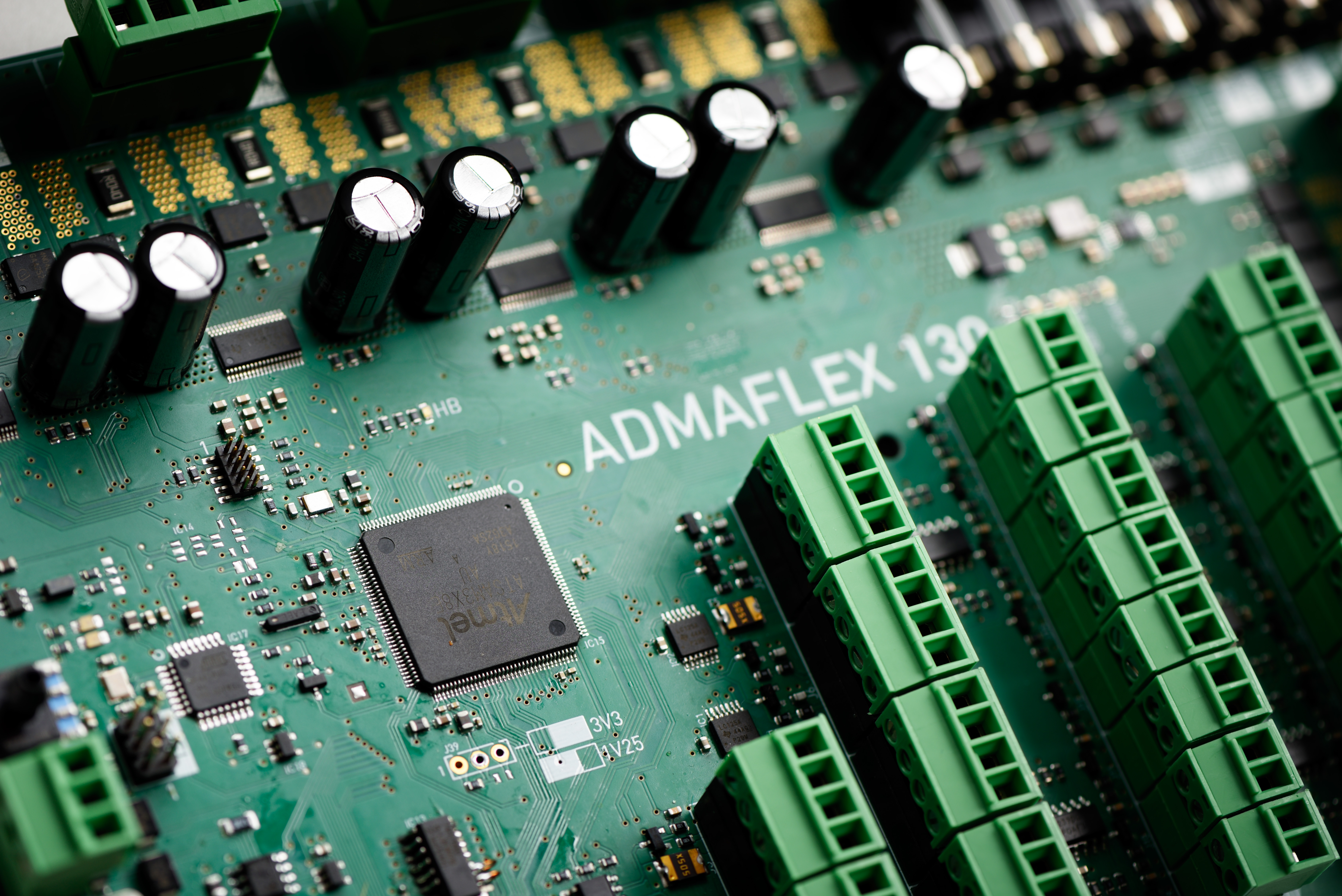

Modular concept

The Admaflex 300 is designed with a modular concept, to accommodate all future developments. but also enables you to make the configuration that suits you best. One option is multi-material printing (also known as hybrid 3D printing)Next to that, you can choose the resolution and building volume that meet your needs.

BENEFITS

- Custom to your needs and budget

- Access to future upgrades

- Best value for money

Open platform

The Admaflex 300 is an open system that provides full control of the printing process. The software features the ability to customize parameters, enabling layer-to-layer control before and during the printing process. It opens up the opportunity to use different and even multi-materials, and the flexibility to develop new ones. A standard software feature is the “multi-part printing”, that enables you to control light exposure settings for each part and layer.

Benefits

- Research and development freedom

- Open to the use of your own and other materials

- Increased efficiency

In-process monitoring system

The integrated in-process quality monitoring is an excellent feature for full traceability of the printing process. These software and hardware components monitor temperature, humidity and foil usage. Real-time video capture and time-lapse recording are standard features of the monitoring system. It allows the user for example to partially stop printing a defected product to allow the successful finalization of all remaining parts. All production data are stored in logfiles with documented proof of the printing process.

Benefits

- Realtime process monitoring for full traceability

- Enhanced usability with remote live video transmission

- Receive warnings and pause the print automatically when a problem is detected

- Increased throughput and efficiency

FR

FR