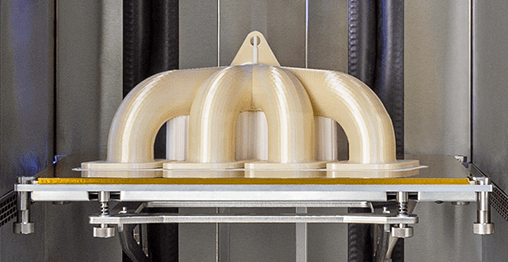

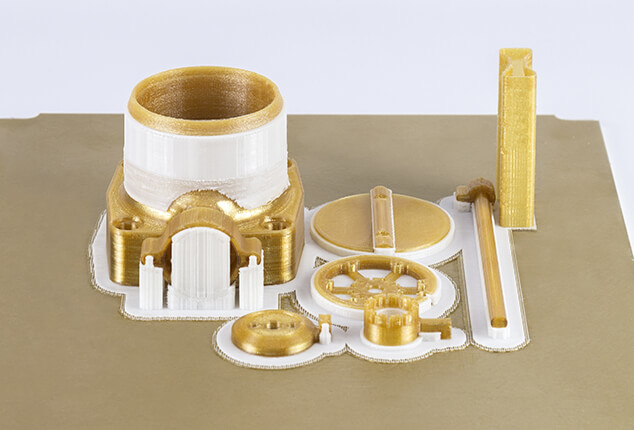

The endureal has advanced thermal management to work efficiently with high performance polymers (PEEK, Z-PEEK, Z-PEI 1010 and 9085). This allows it to more closely control precision and achieve better mechanical properties by 3D printing in an industrial environment.

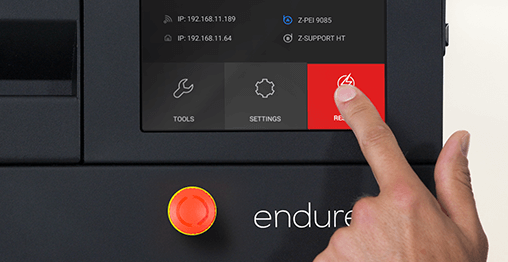

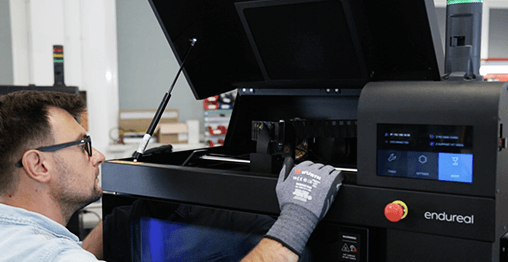

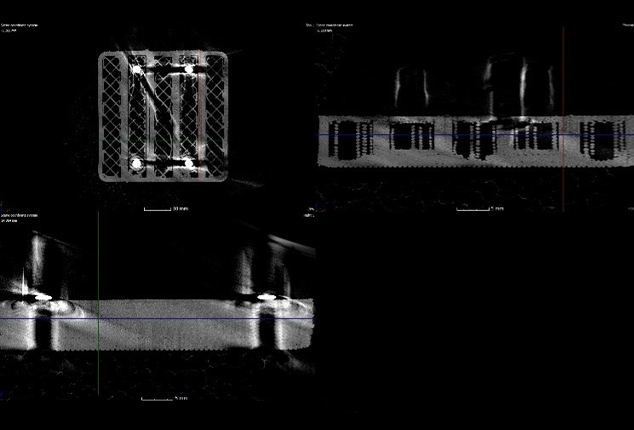

The high temperature of the chamber allows it to anneal to obtain the highest mechanical properties of the materials at high temperature. The maintenance of the Endureal is facilitated by the maintenance kit provided allowing to repair on site without cancelling the warranty. The various sensors allow to control the amount of remaining wire and its supply, the in situ camera allows to control the printing despite the demanding conditions.

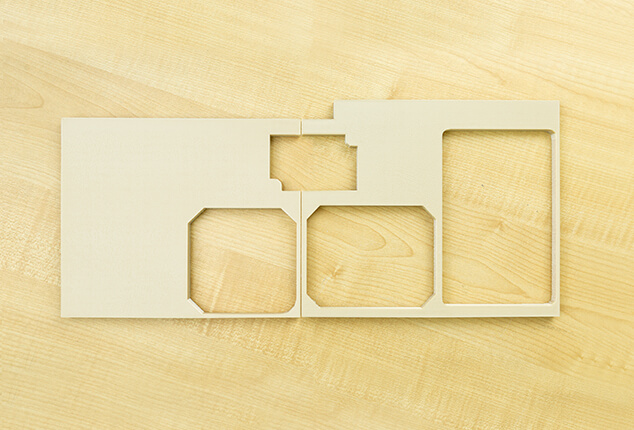

Zortrax printers can be easily inserted into a production line by also adding more Appoller devices to expand post-processing capabilities. This makes it possible to quickly and easily scale up production with agility.

FR

FR