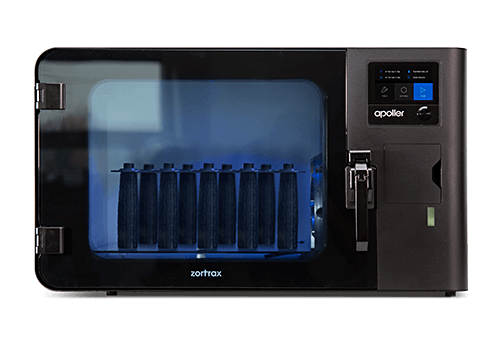

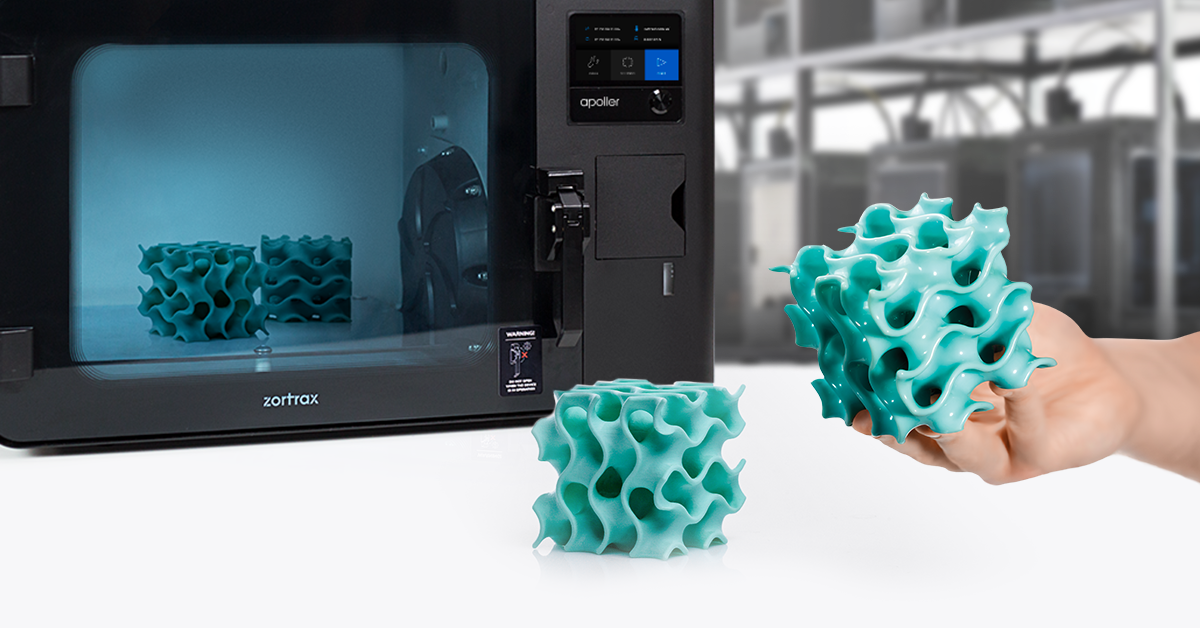

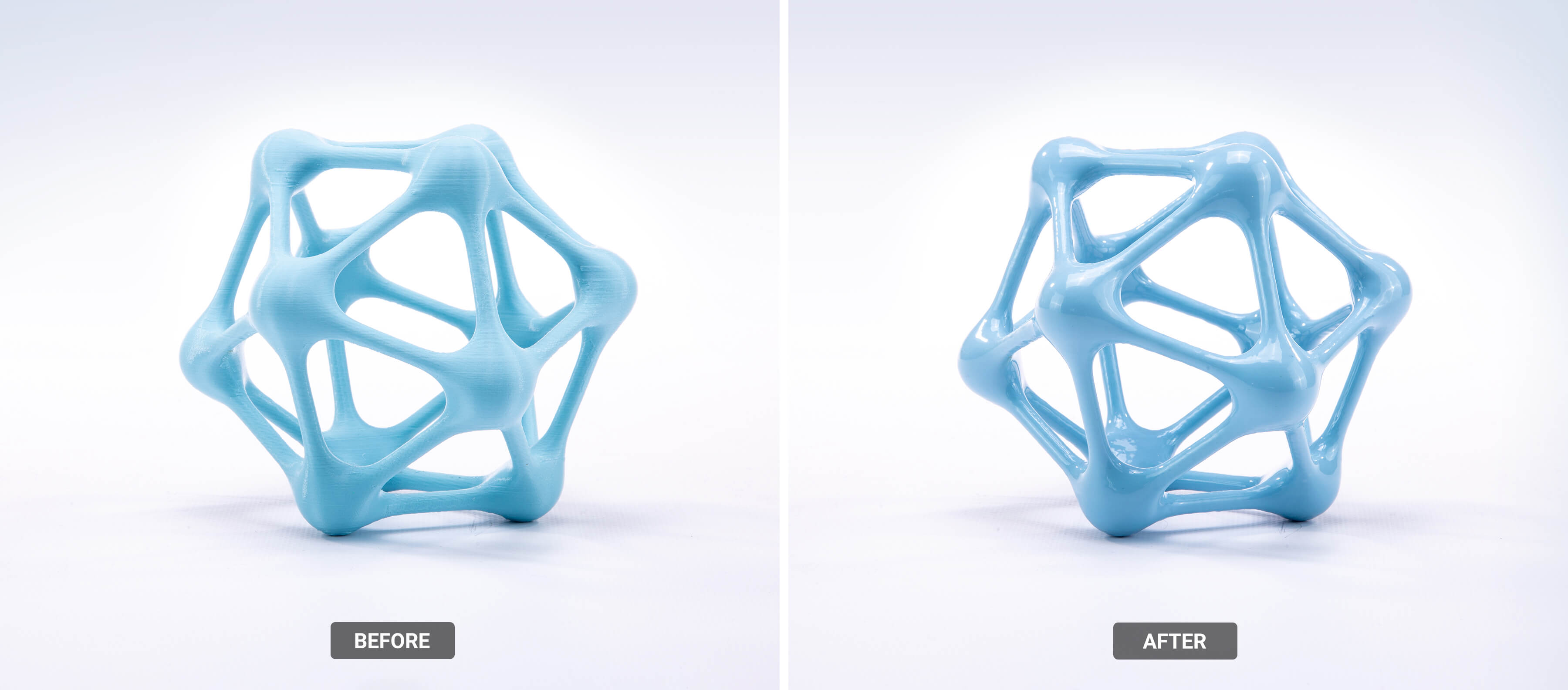

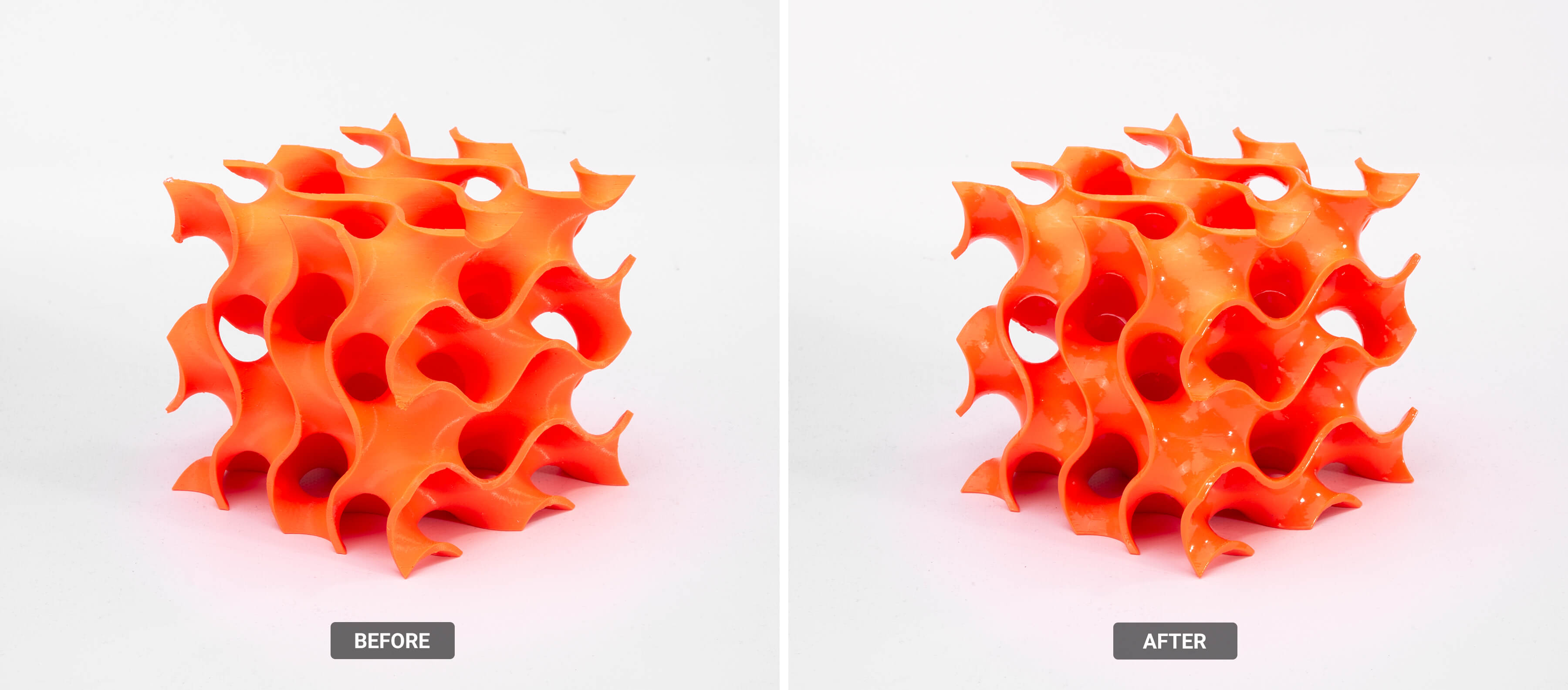

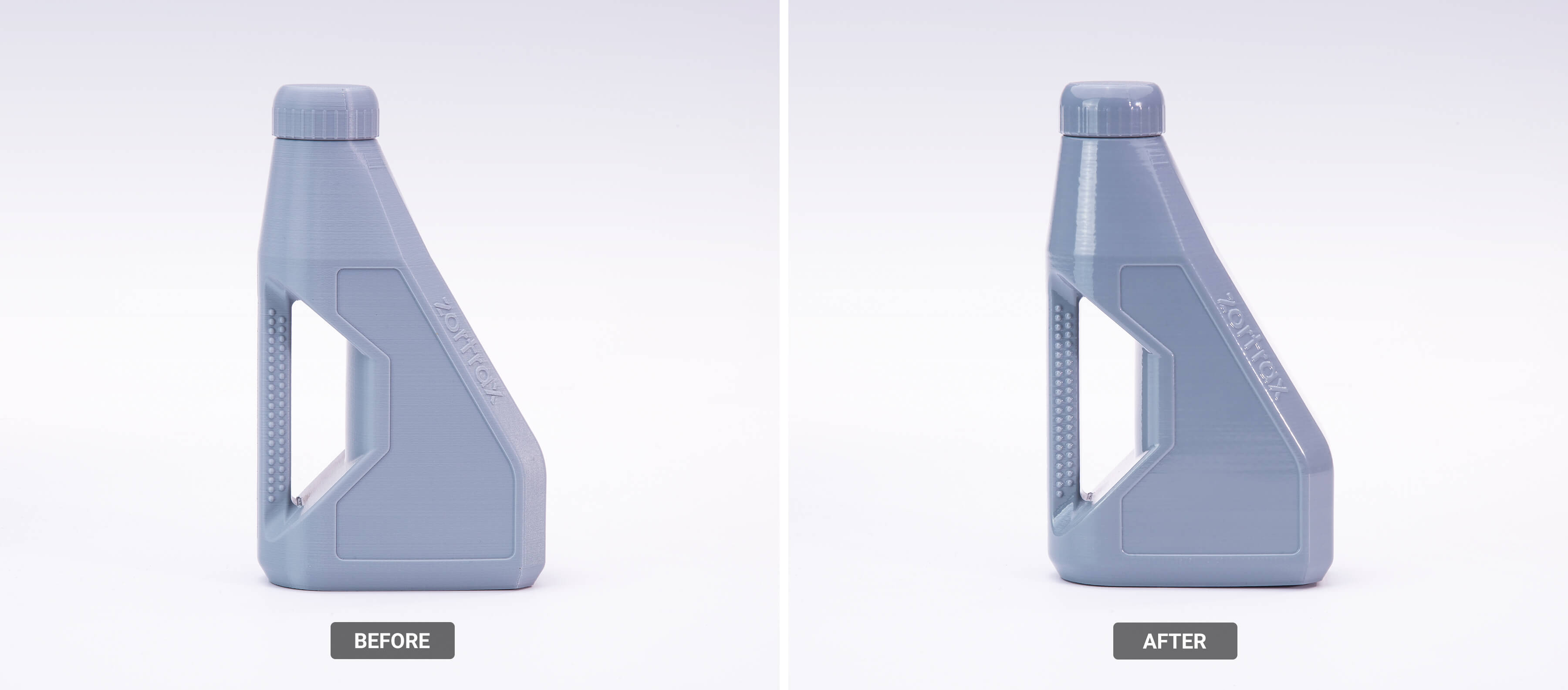

Smart Vapor Smoothing (SVS) is a post-processing technology that uniformly smoothes surfaces on all types of models, including those with complex geometries and interlocking moving parts. This is achieved by automatically managing the temperature, pressure and concentration of solvent vapors in the Apoller’s smoothing chamber.

This technology is compatible with all 3D printers FDM, FFF, DLP; and is compatible with all filaments based on ABS, HIPS and ASA regardless of their manufacturer. It allows to easily adapt its production; this solution can be easily integrated in a production center. Production farms will be able to manufacture products with a quality comparable to that of injection molding at a reduced price.

FR

FR