SmartBench Precision Pro X

As an improvement on the SmartBench Precision Pro +, the PrecisionPro X includes all the elements that made the previous models popular : mounted in a few minutes, easy transportation in an utilitary vehicle and ease of use even for new to cnc users.

With the Smartbench PrecisionProX, you get an innovative CNC with smart automations as the YetiPilot feature.

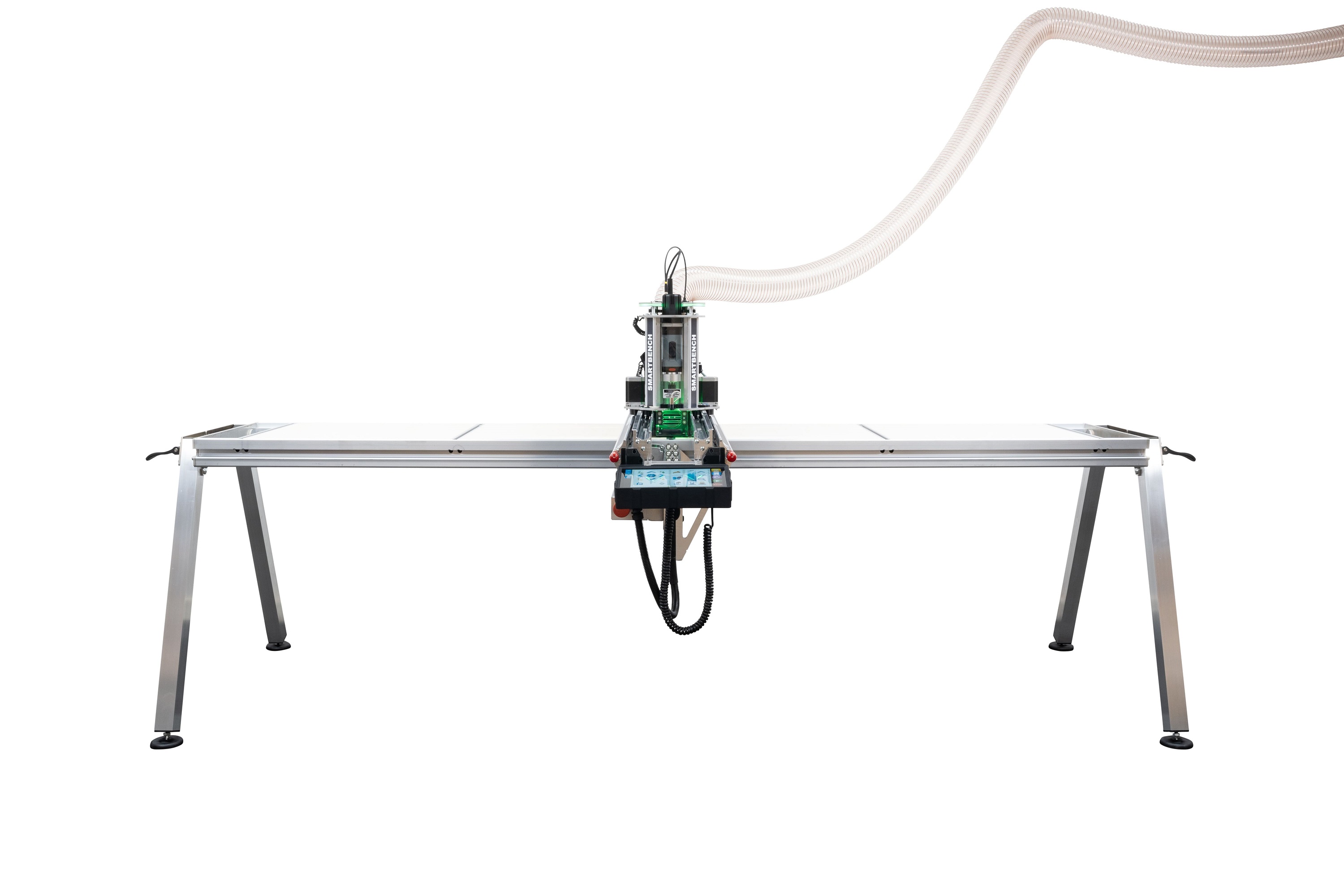

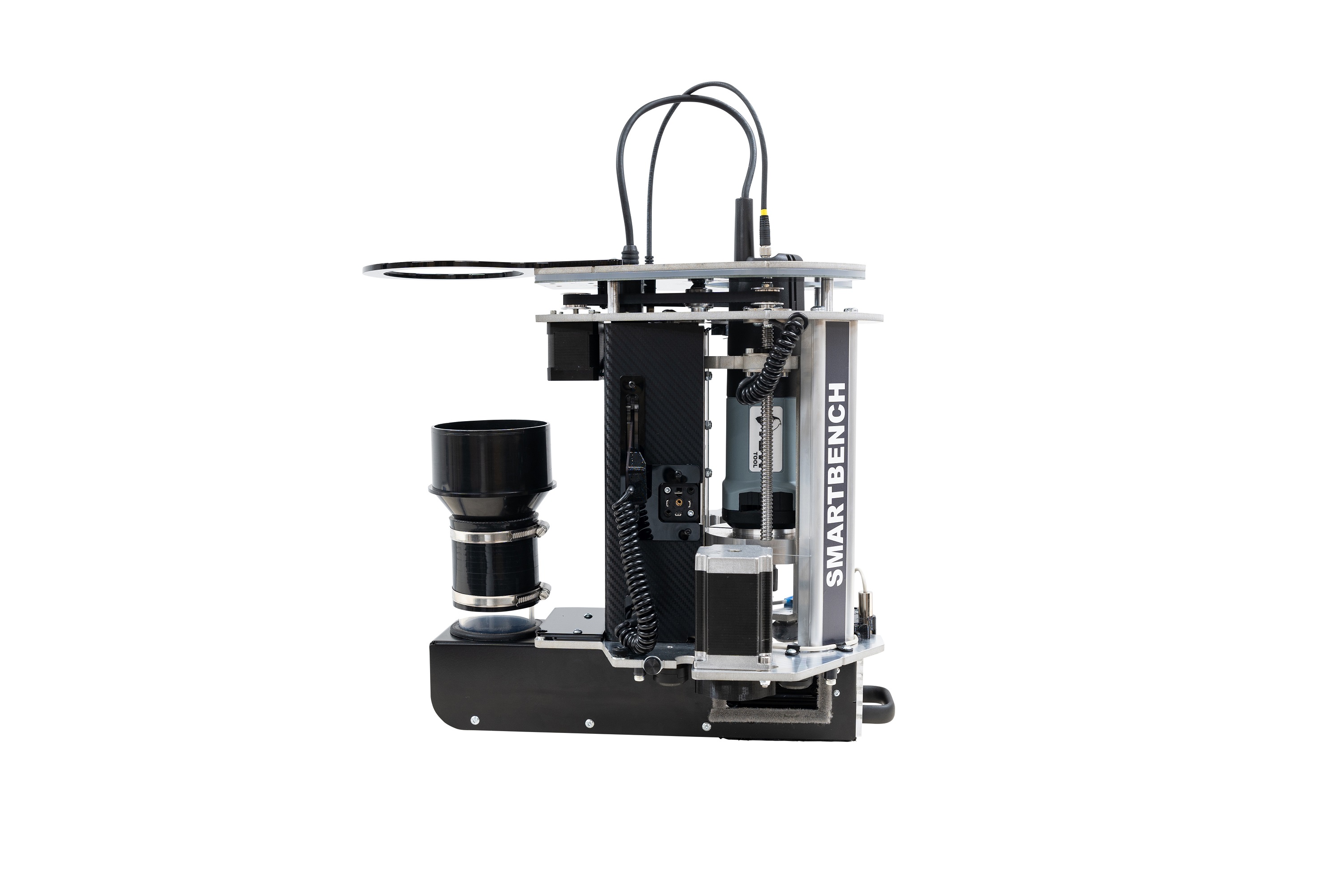

The PrecisionPro X integrates the BigFoot system for industrial quality vacuum dust extraction allowing you to have a work surface that is always clean thanks to its 100mm connection and pipe designed to adapt your industrial vacuum unit.

The PrecisionPro X proves to be a long-term investment because the machine offers regular updates, so its software is never obsolete. In addition, the manufacturer Yetitool develops upgrades so that its customers can always access the new features offered on the latest machines released.

Autonomous operation

The Smartbench range makes the use of the CNC accessible to as many people as possible with intelligent and practical features making these machines very easy to use even for beginner users. The PrecisionPro X is no exception to this rule, with a fully automated control system, you can no longer go wrong.

The YetiPilot reacts according to the spindle load, its feedrate and the type of cutter. The software automates the speed setting process and drastically reduces the margin for error. In fact, YetiPilot saves time with acceleration of up to 200%, you will no longer have to monitor the progress of the cut yourself to adapt the speed, and money thanks to a more significant yield due to optimized workflow and strong limitation of human errors.

Easy handling and setup

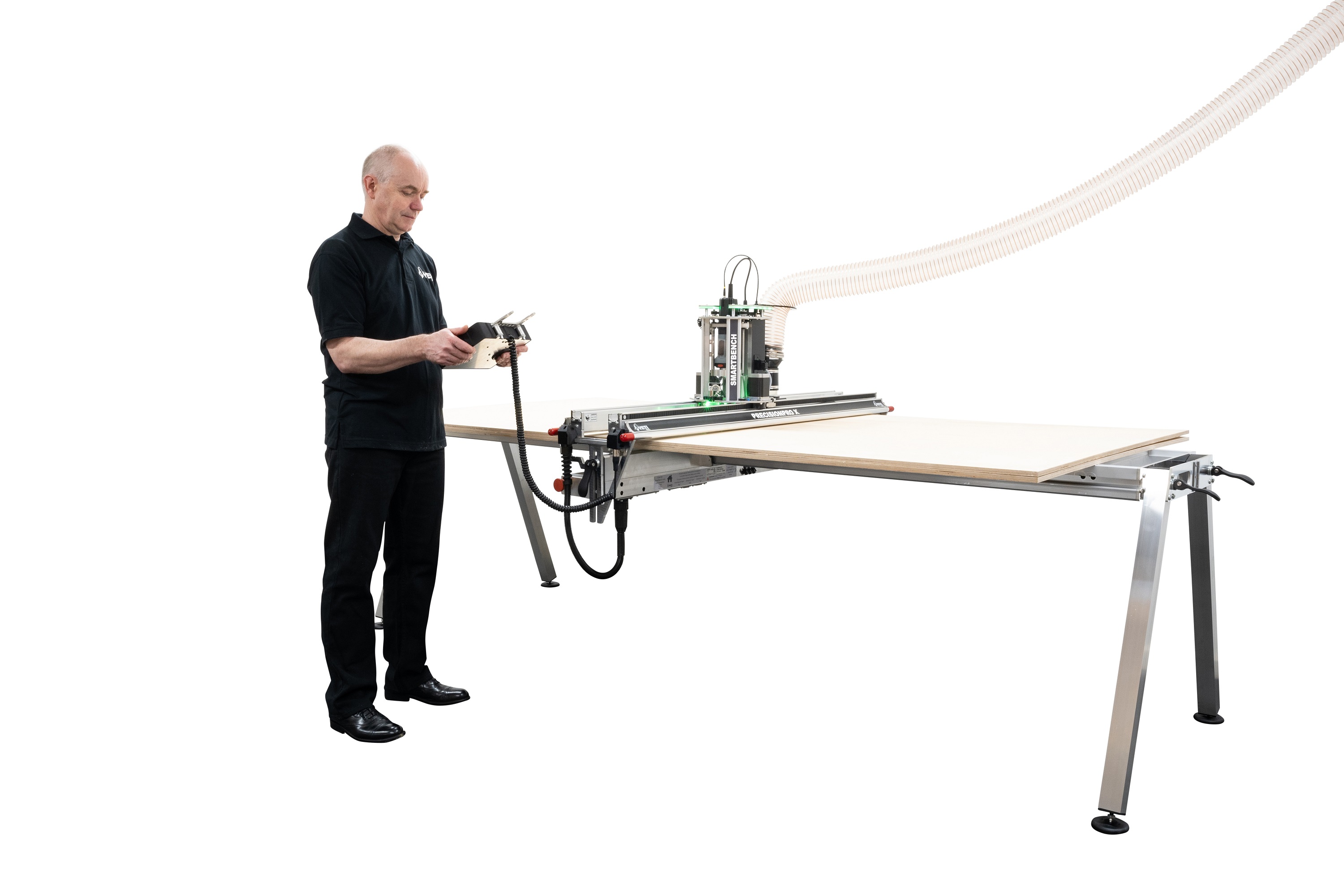

Delivered pre-assembled, it only takes a few minutes to unpack and start your first projects.

The Shapes application guides you step by step to make your first cuts without even using a computer.

The PrecisionProX is a SmartBench with a 10.1 inches touchscreen making operations simpler and smoother for an improved workflow.

With on-site assembly in just 3 minutes including the installation of the BigFoot, the YetiTool CNC milling machine can easily adapt to any type of environment due to the little space it occupies. With a machining width of 1250 mm, a length of 2500 mm and a maximum depth of 152 mm, the PrecisionPro X is very versatile. It makes it possible to process large surfaces without the constraints of traditional large format CNCs.

To summarize, the PrecisionPro X offers autonomous cutting, an efficient dust and chips vacuum system, calibration control and automatic feedrate adjustment. You will therefore have plenty of time to concentrate on other tasks while your machine takes care of everything!

Compatible materials

Many materials can be worked with the PrecisionPro X:

- Softwood, hardwood, MDF, HPL, plywood, etc.

- Mineral materials such as Corian, Hi-Macs, etc.

- Plastic materials: Acrylic, PVC, etc.,…

- Rubbers and technical foams

- Non-ferrous soft metals

- Composite materials such as Dibond or carbon fiber

Non-exhaustive list of materials, many other compatible materials can be experimented with.

Safety emphasized

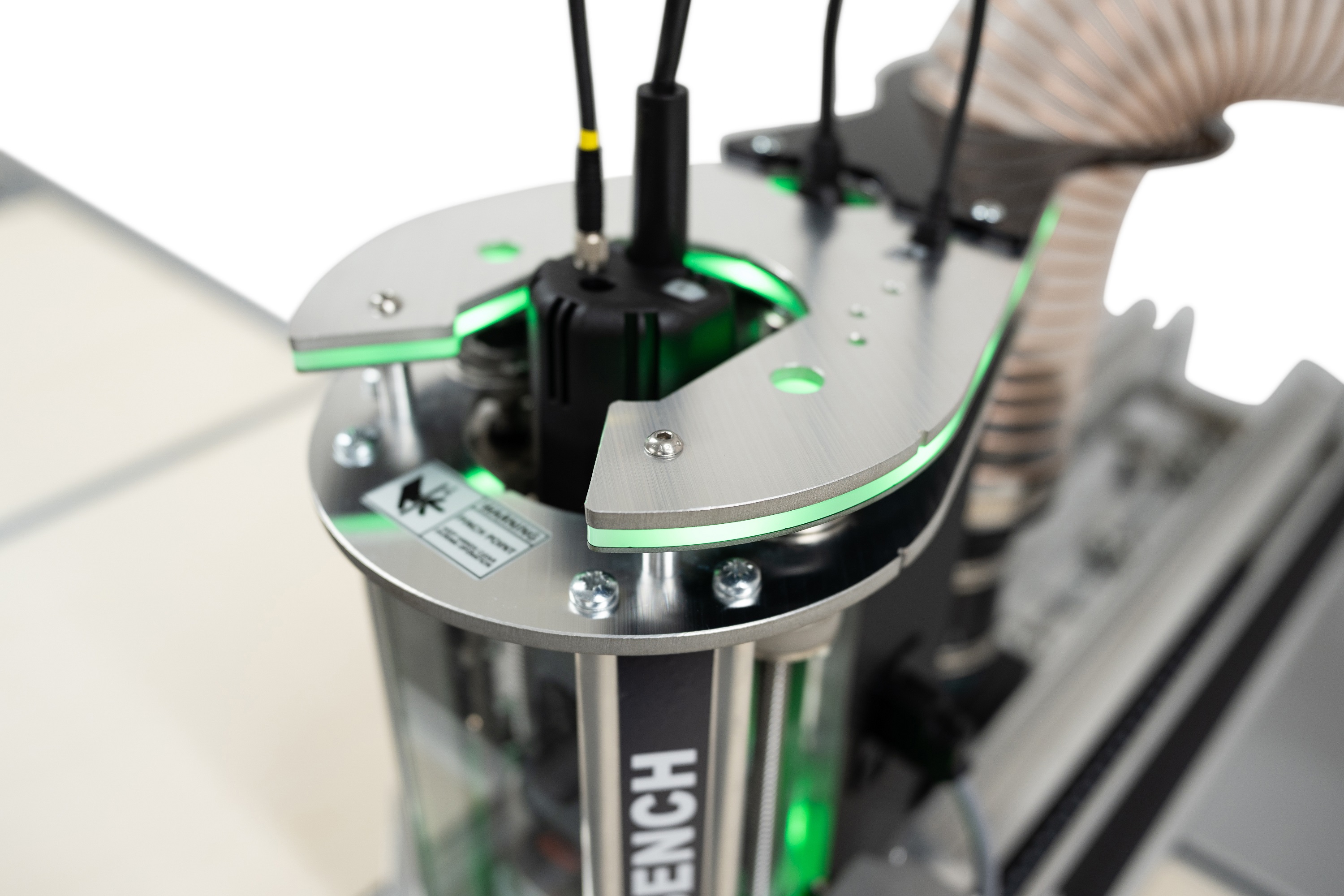

Designed and manufactured in England, Yetitool machines meet European safety standards and have an easily accessible emergency stop in the event of a problem. Add to this the X-axis stop-bars for even more safety. These detect any element obstructing the movement of the machine such as fingers on the rails or a tool left on the table and automatically trigger the emergency stop.

In addition, the various permanent controls of the YetiPilot help reduce the risk of accidents. The spindle is inspected in real time by the machine’s internal software and the BigFoot has color-coded light halos that indicate the operating status of the machine. These very practical indicator lights allow you to know whether the machine is working correctly without standing next to it.

FR

FR