Smartbench PrecisionPro + mini

Smart features for easy and convenient use

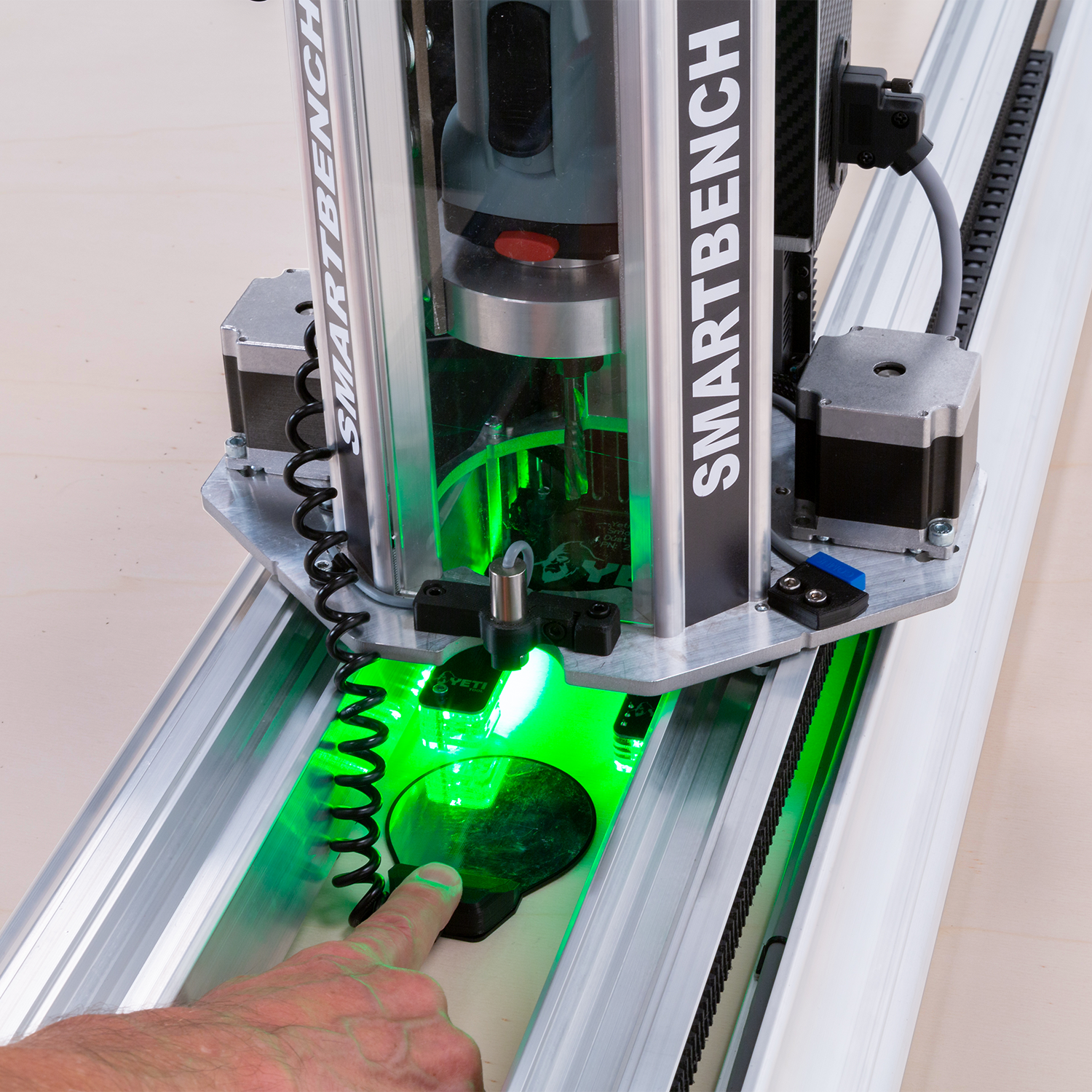

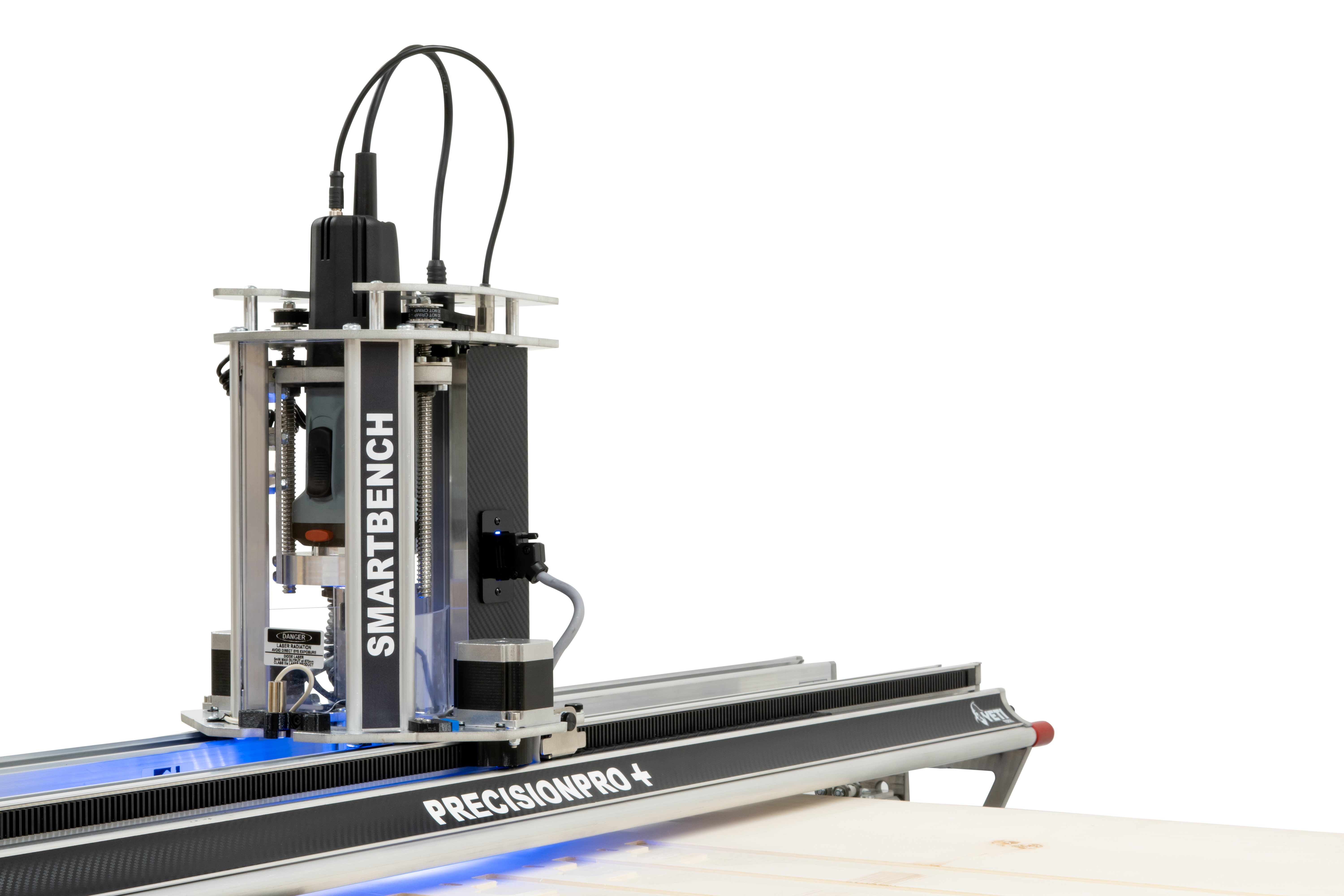

The PrecicionPro+ mini innovates by integrating the Yeti Pilot function allowing it to perform machining at adaptive speed. Thus, the machine can speed up or slow down the feedrate depending on the load on the spindle. To do this, YetiPilot listens 50 times per second to the spindle in order to identify the load on it. If too much load is identified, the feed rate is reduced. And when a low load is detected, the feed rate increases.

Novice users will no longer have the apprehension of setting the wrong machining data. Launching their projects safely without damaging their material, their cutter and their machine is now possible without any difficulty.

More experienced users will benefit, in addition to a gain in spindle and cutter life, from a saving in production time.

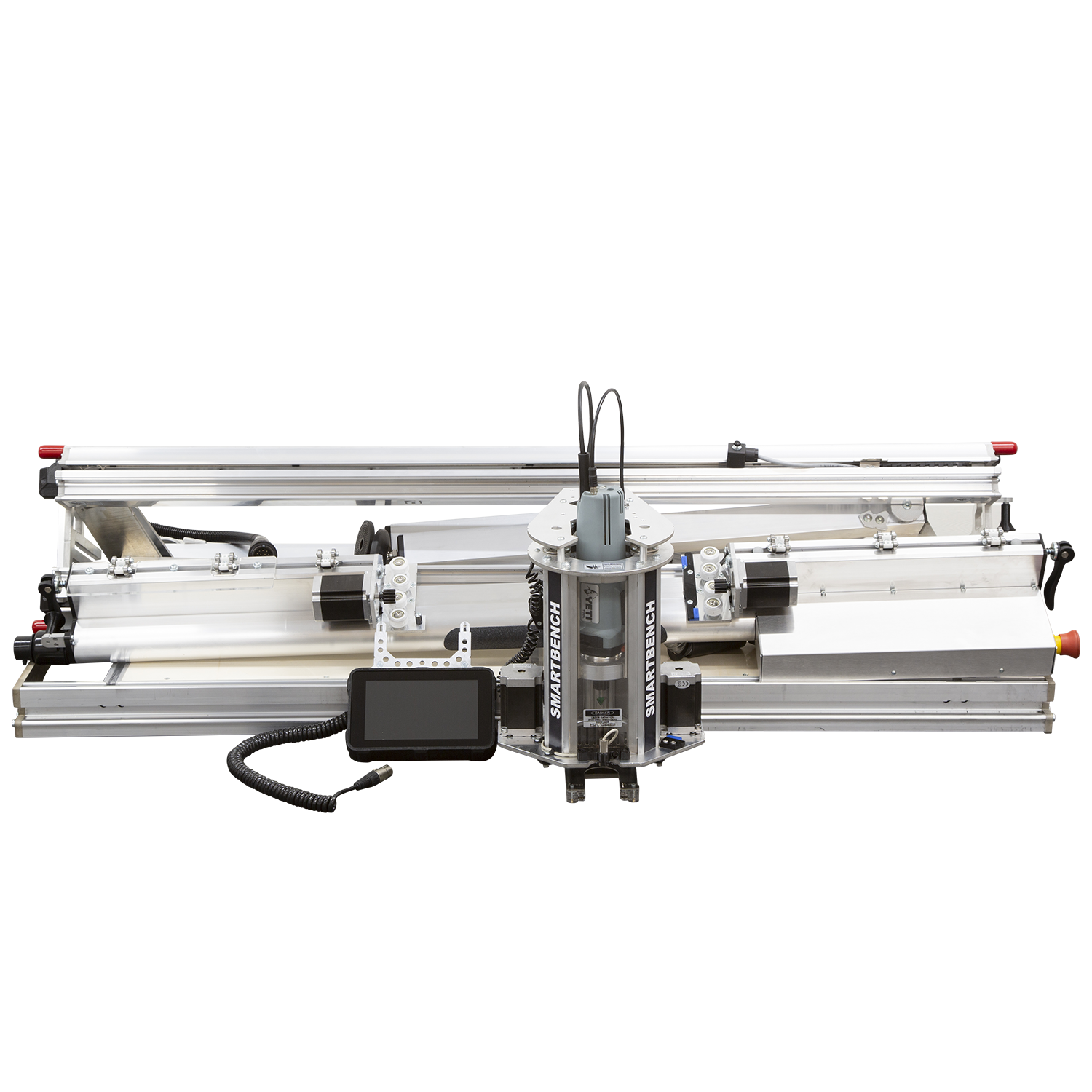

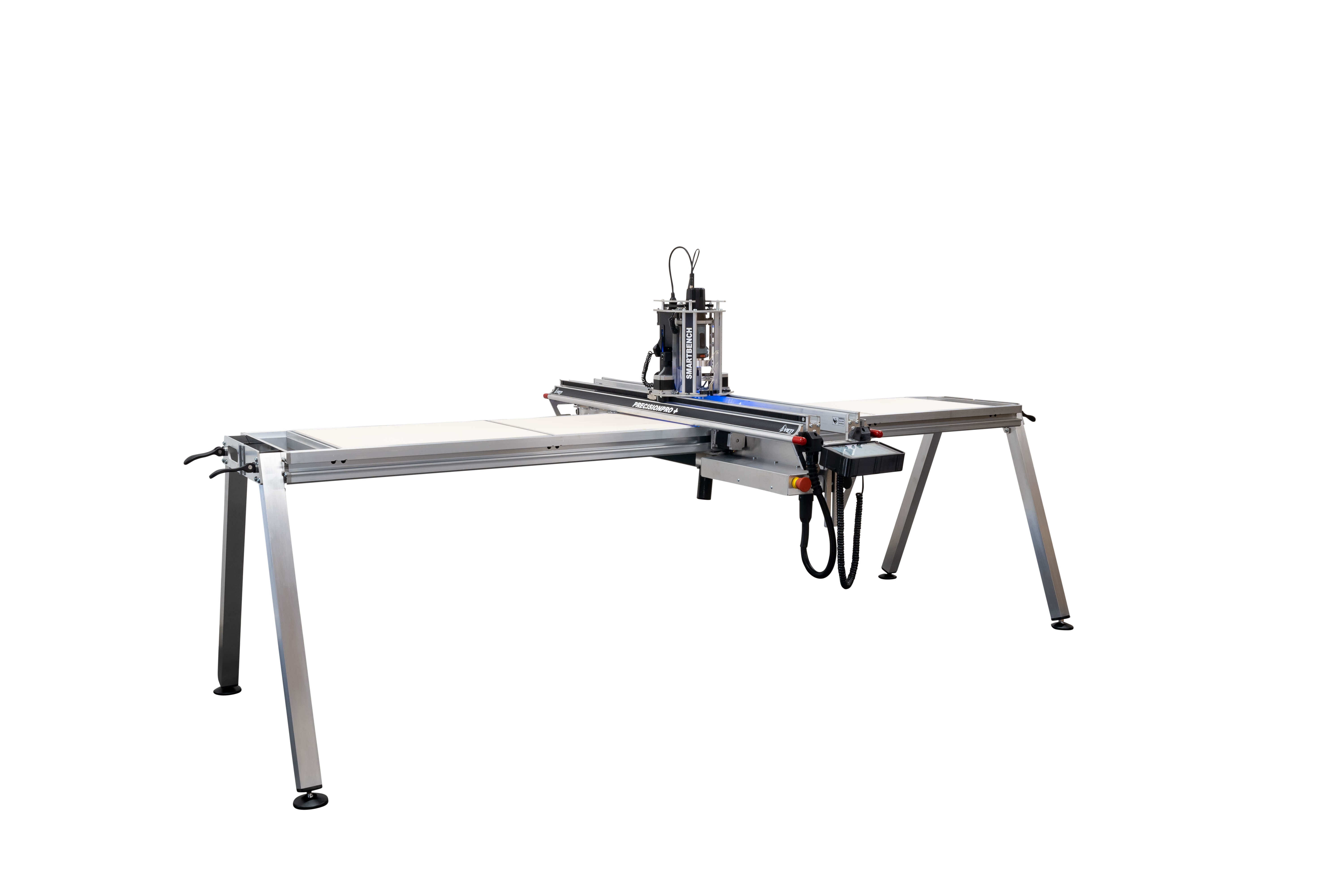

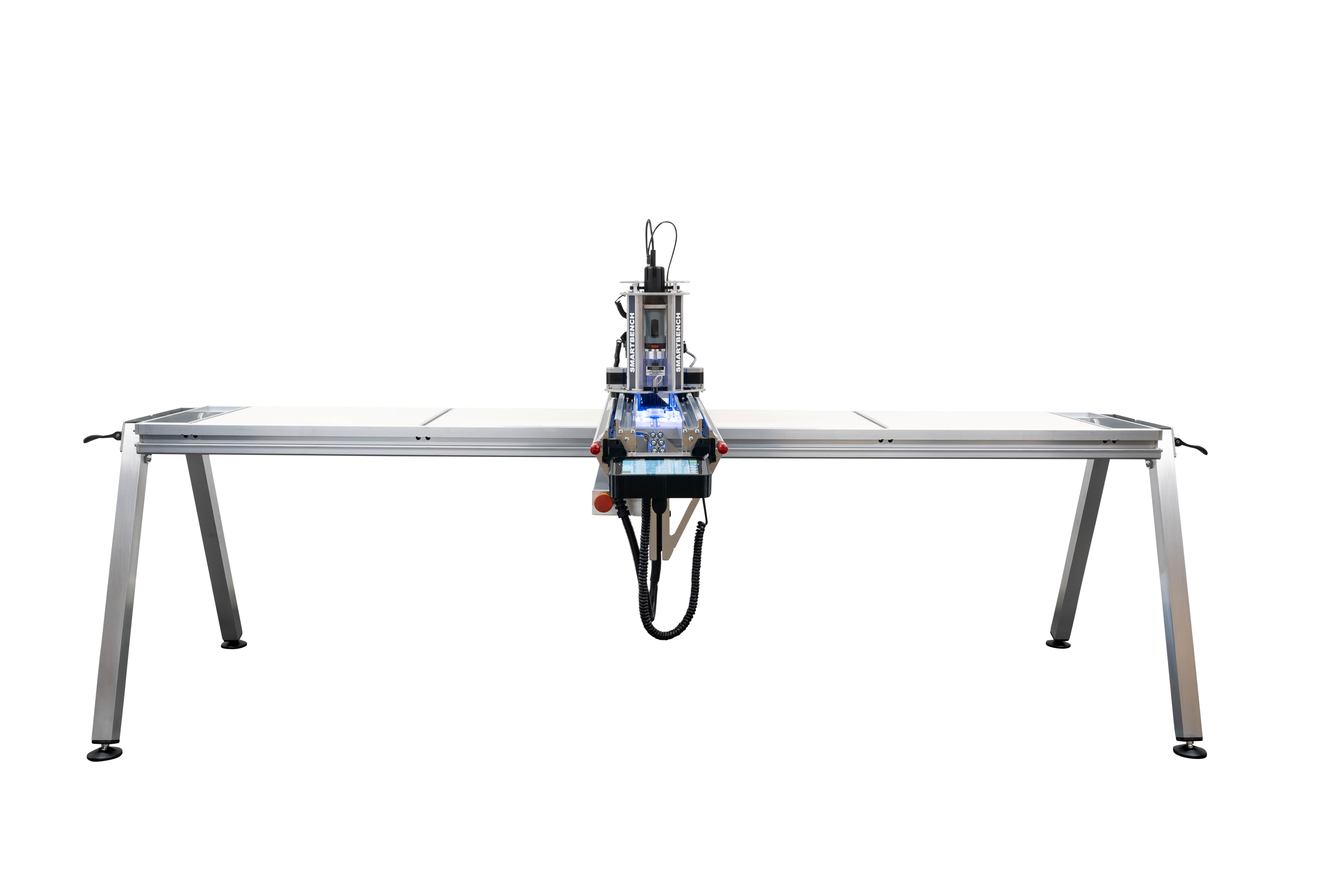

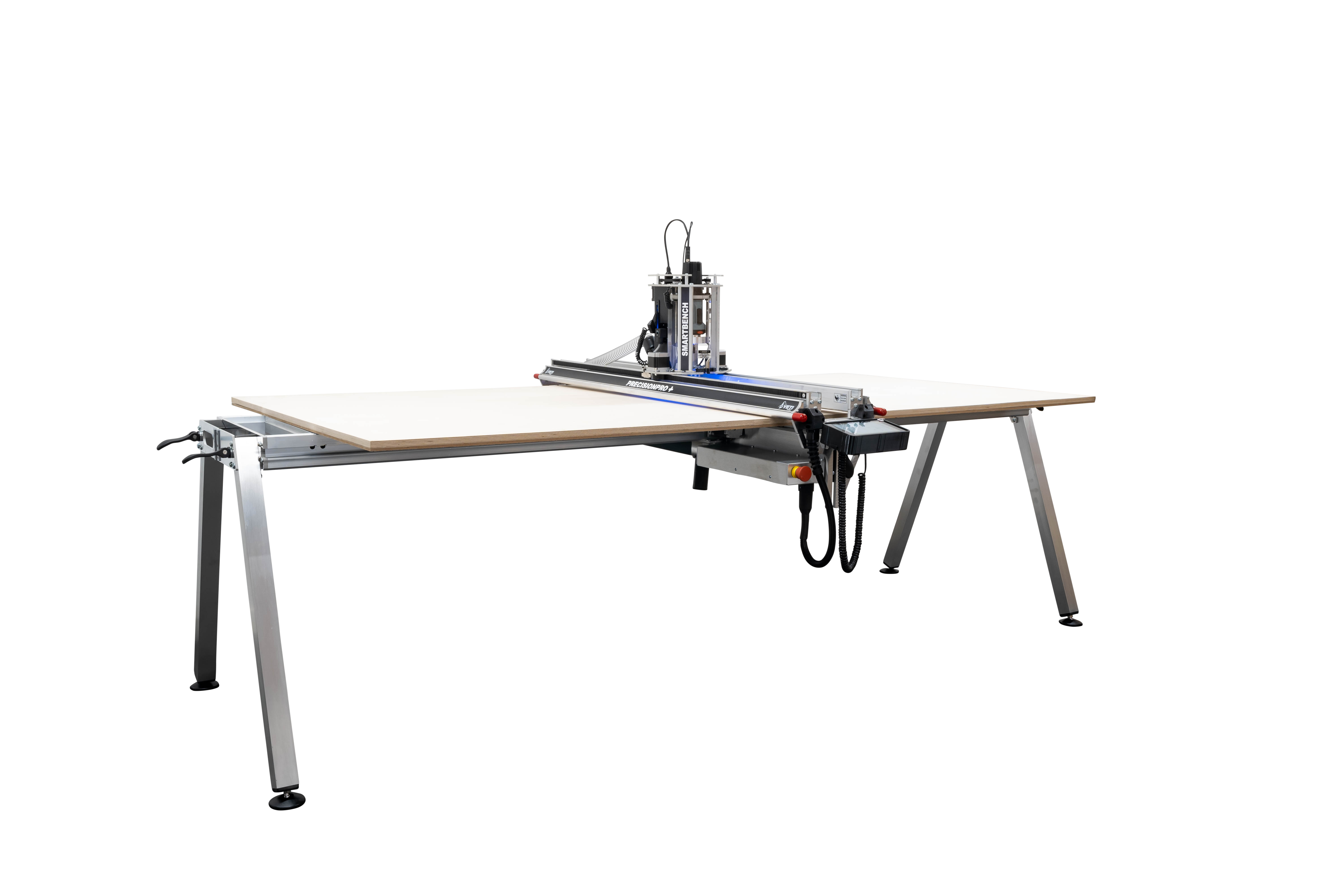

A versatile and mobile CNC

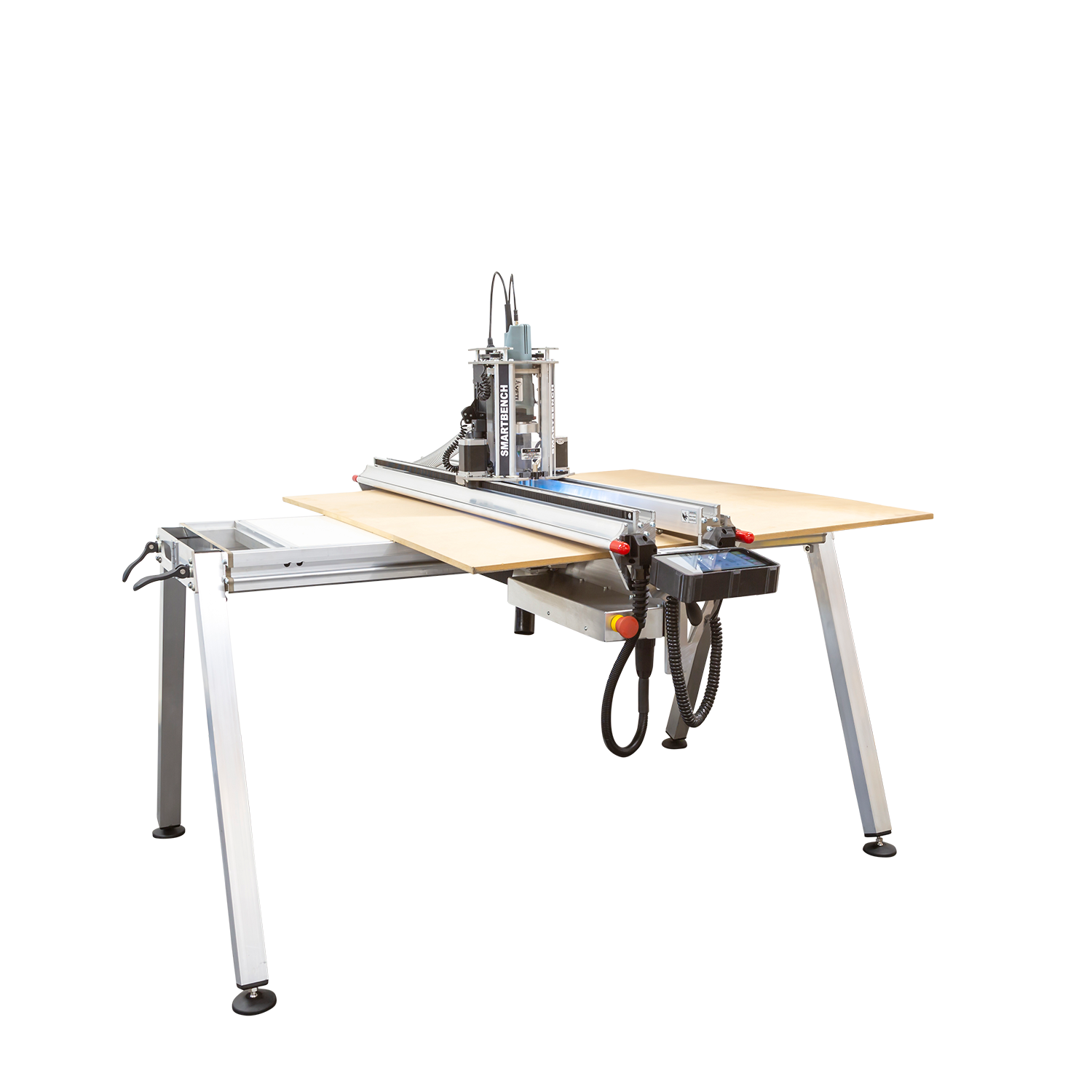

The Smartbench PrecisionPro+ mini can cut a multitude of materials such as hard or soft wood panels, MDF, plywood, various plastics and composites and even aluminum and other soft non-ferrous metals.

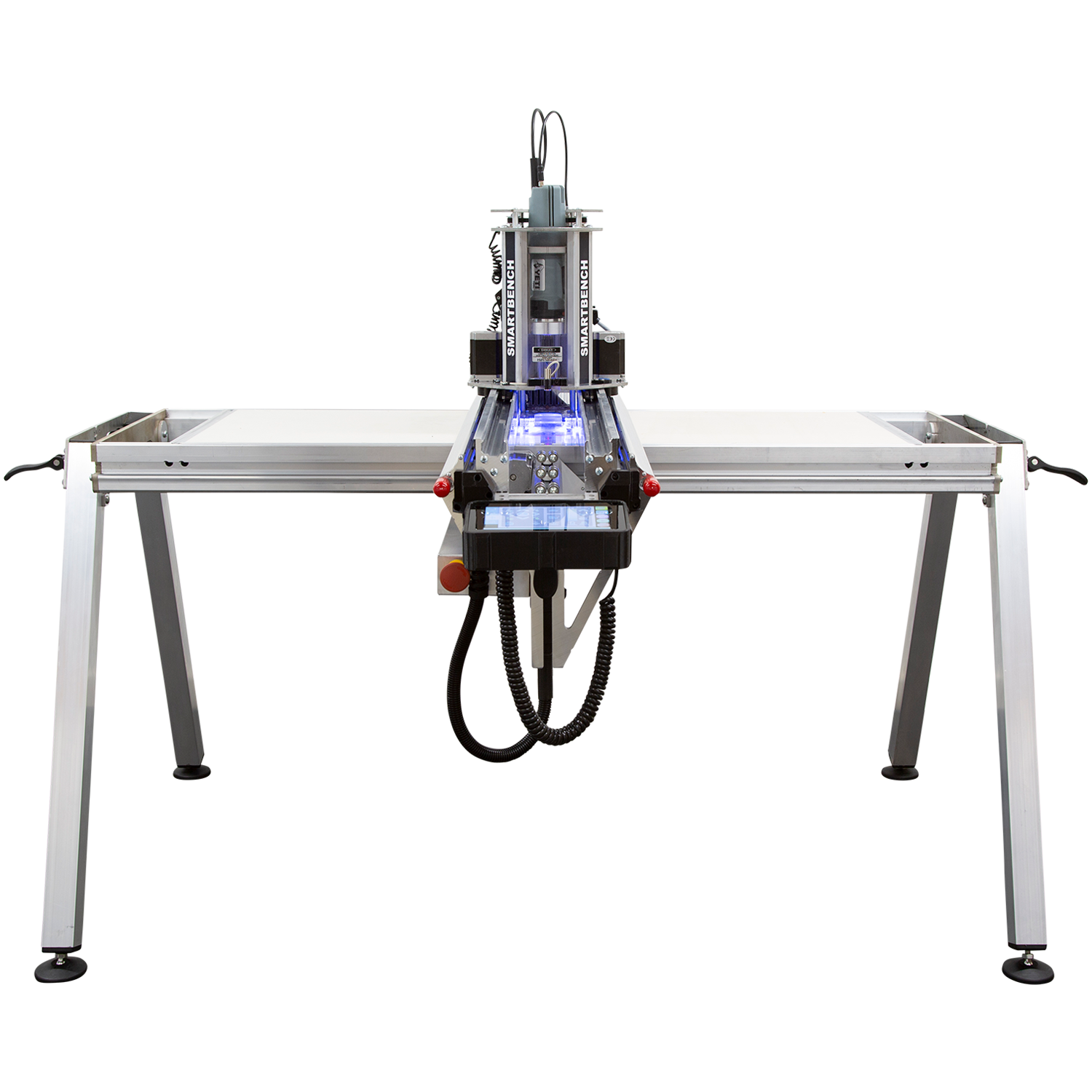

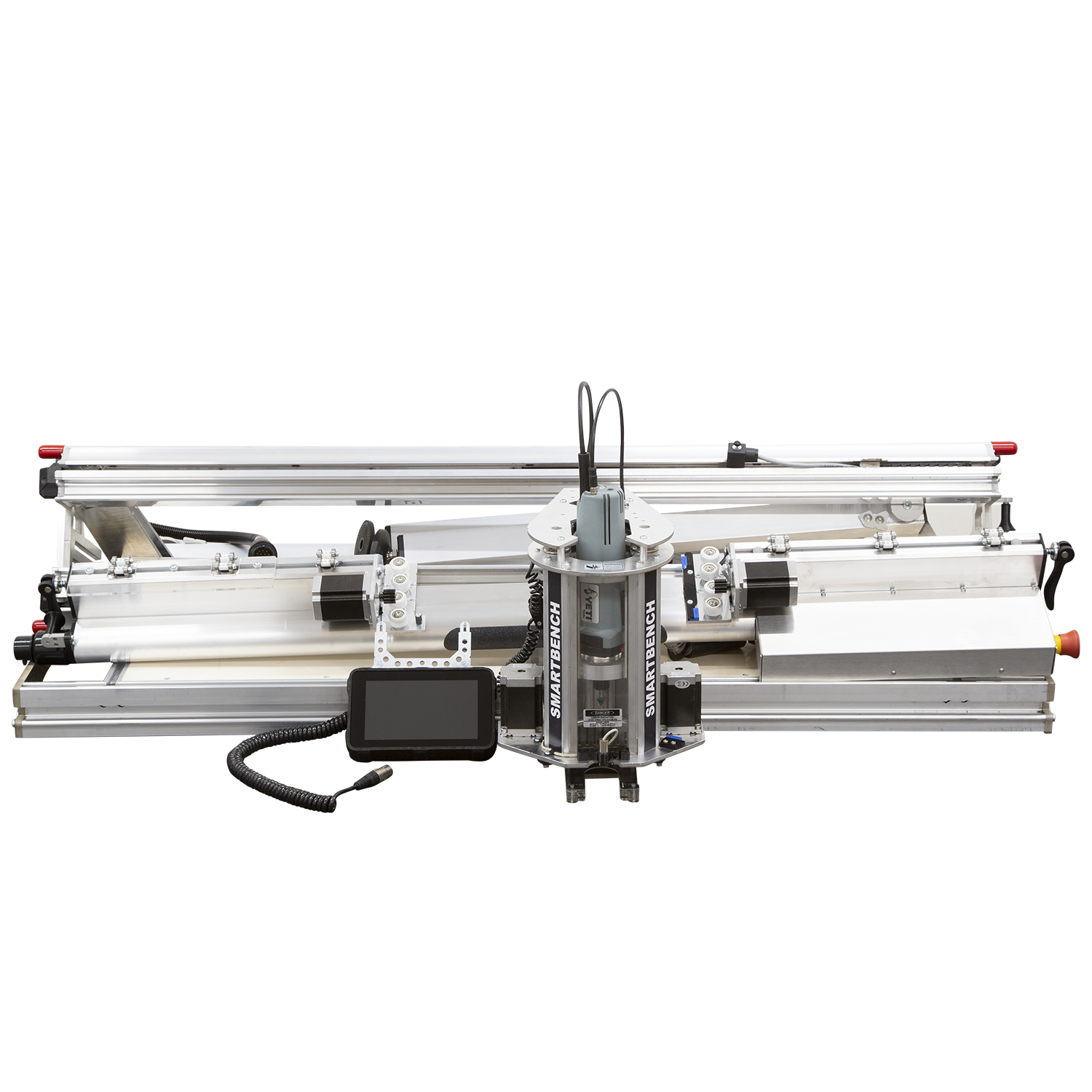

This machine will be able to cut on large surfaces of 1250×1250 mm while being discreet in your workshop due to its small footprint and the possibility of dismantling it for storage.

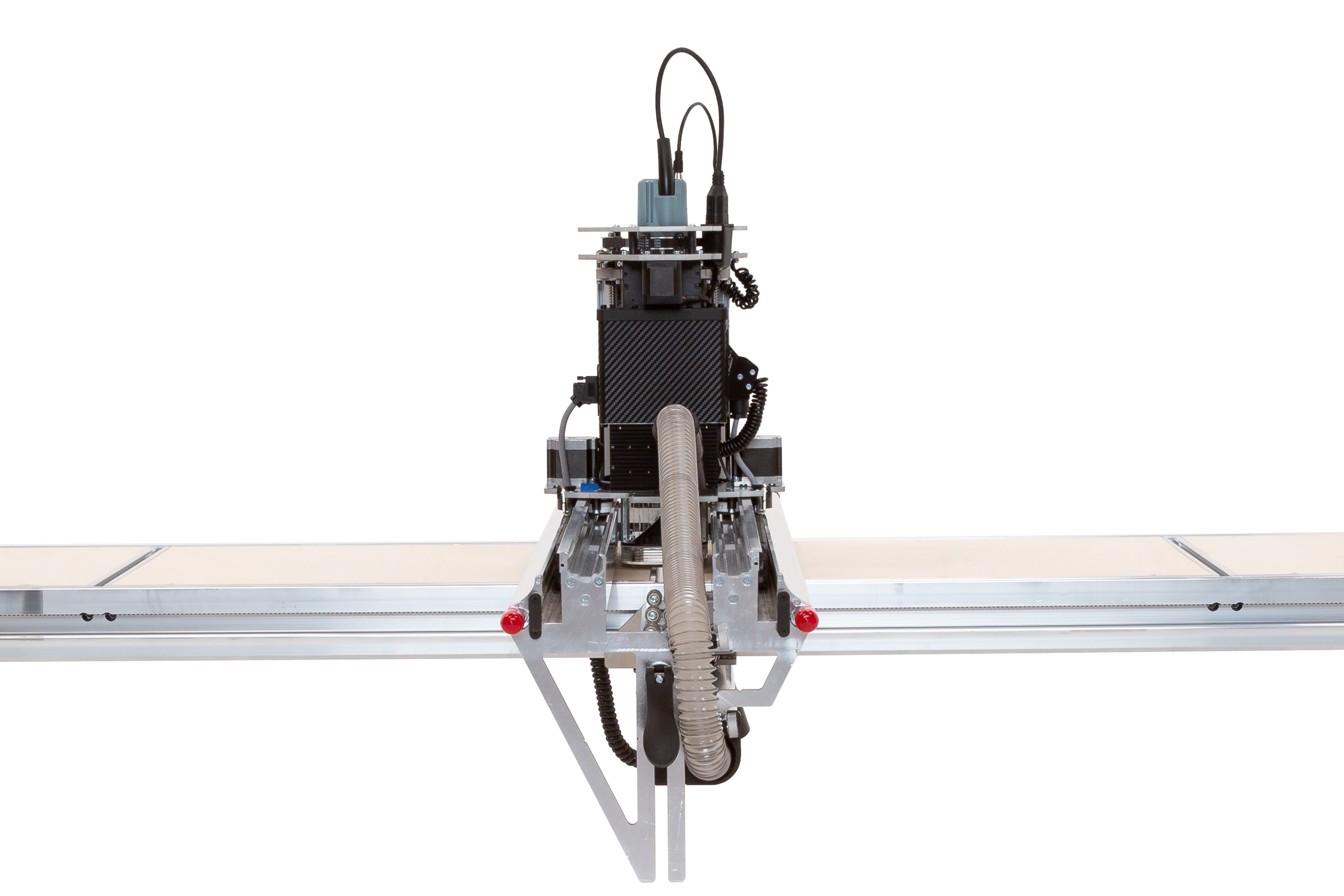

Thanks to its clever system of rollers which flatten the panels to be machined on the table of the machine, the Smartbench PrecisionPro+ mini can easily cut on any support and thus limit or even eliminate the use of tabs, which then makes it possible to have very clean edges on your parts.

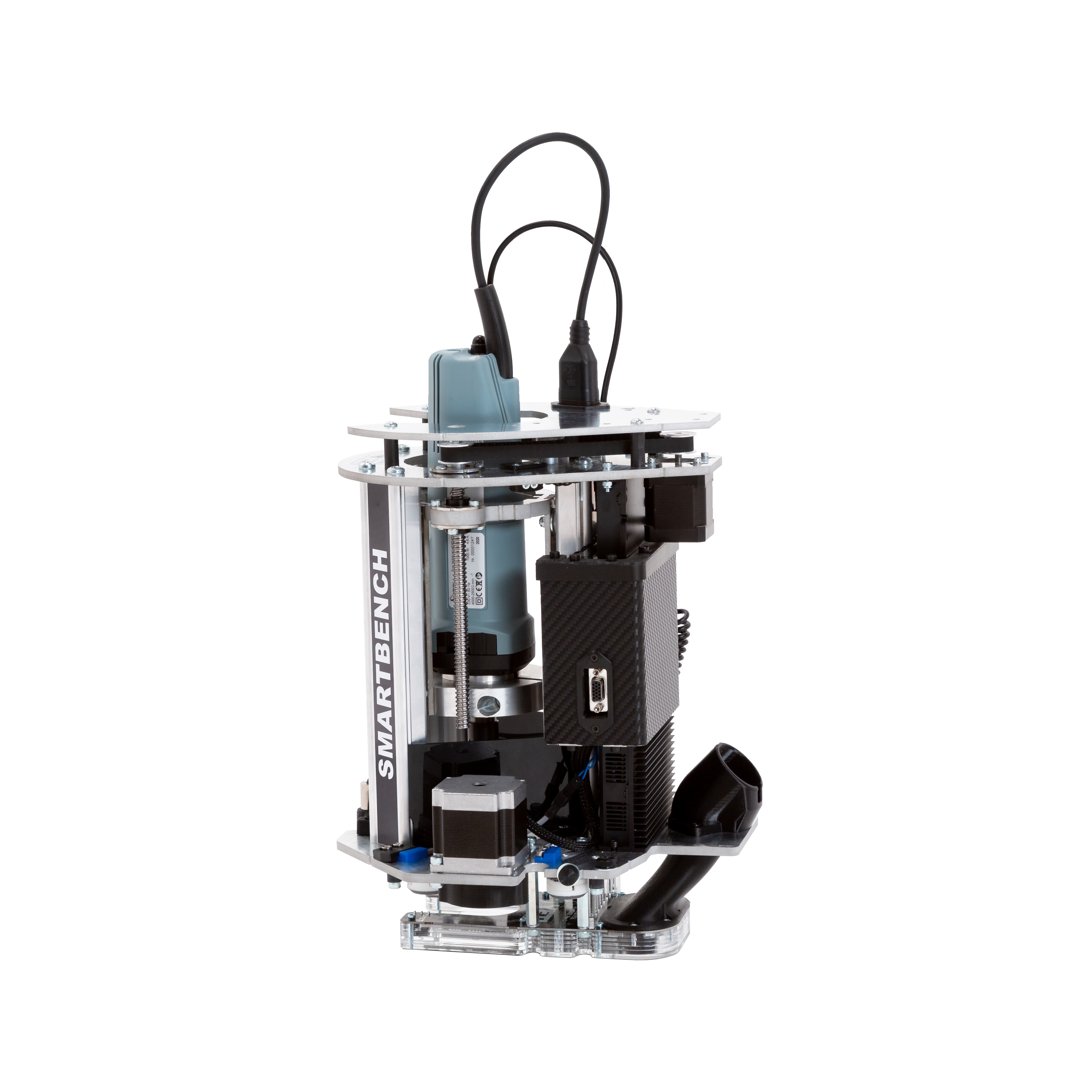

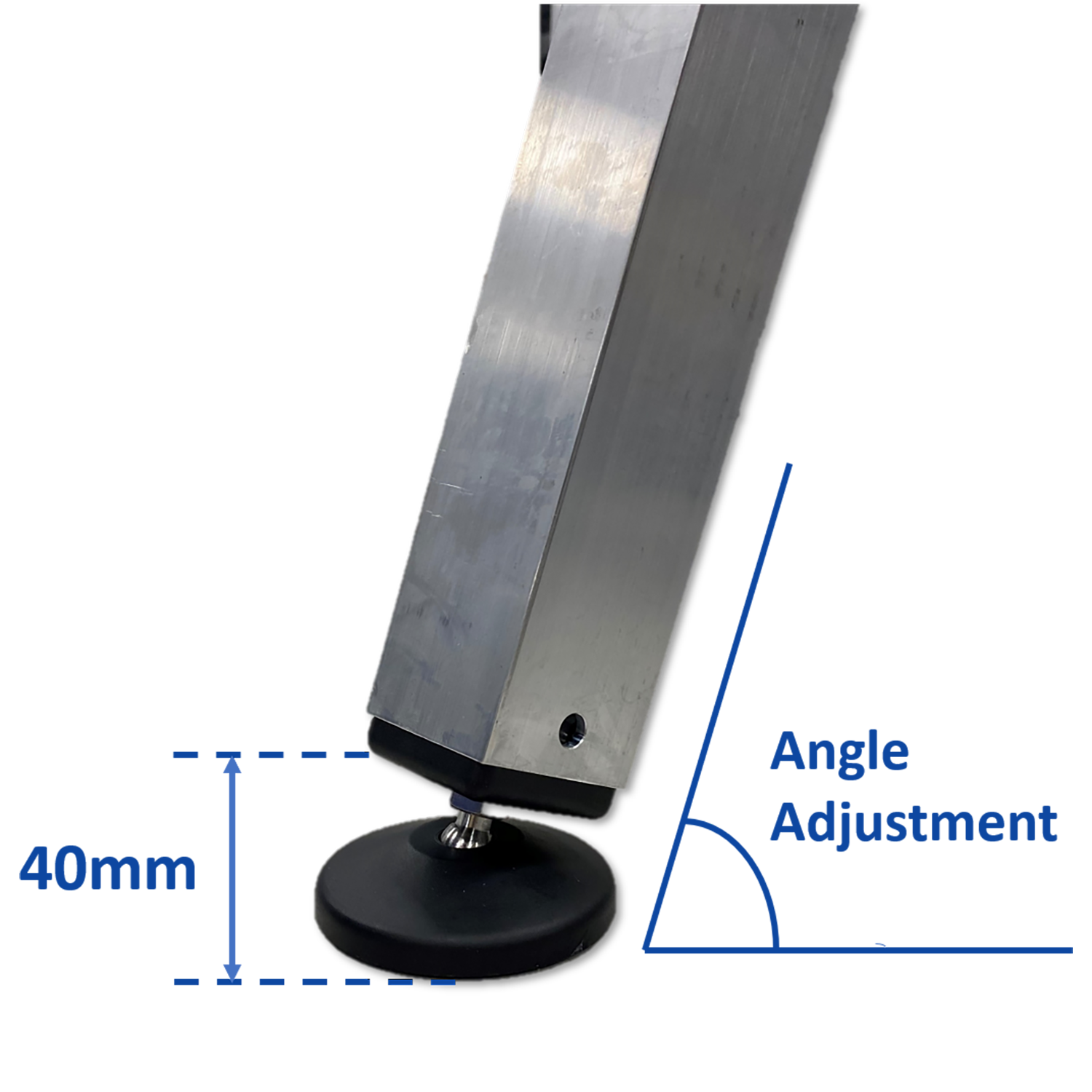

Disassembly and reassembly are done in less than 5 minutes, which makes on-site installation achievable easily by a single person, the PrecisionPro+ mini is then very nomadic and can easily fit into your small utility vehicle or even a car.

It’s very attractive price for Fablabs, the education sector, small craft workshops, home, boat and van fitters, carpenters and much more make it the ideal ally for all types of activities.

The ideal machine for beginners in CNC milling

It has never been easier to launch a production with the Smartbench PrecisionPro+ mini, easy to use and intuitive thanks to many very practical features.

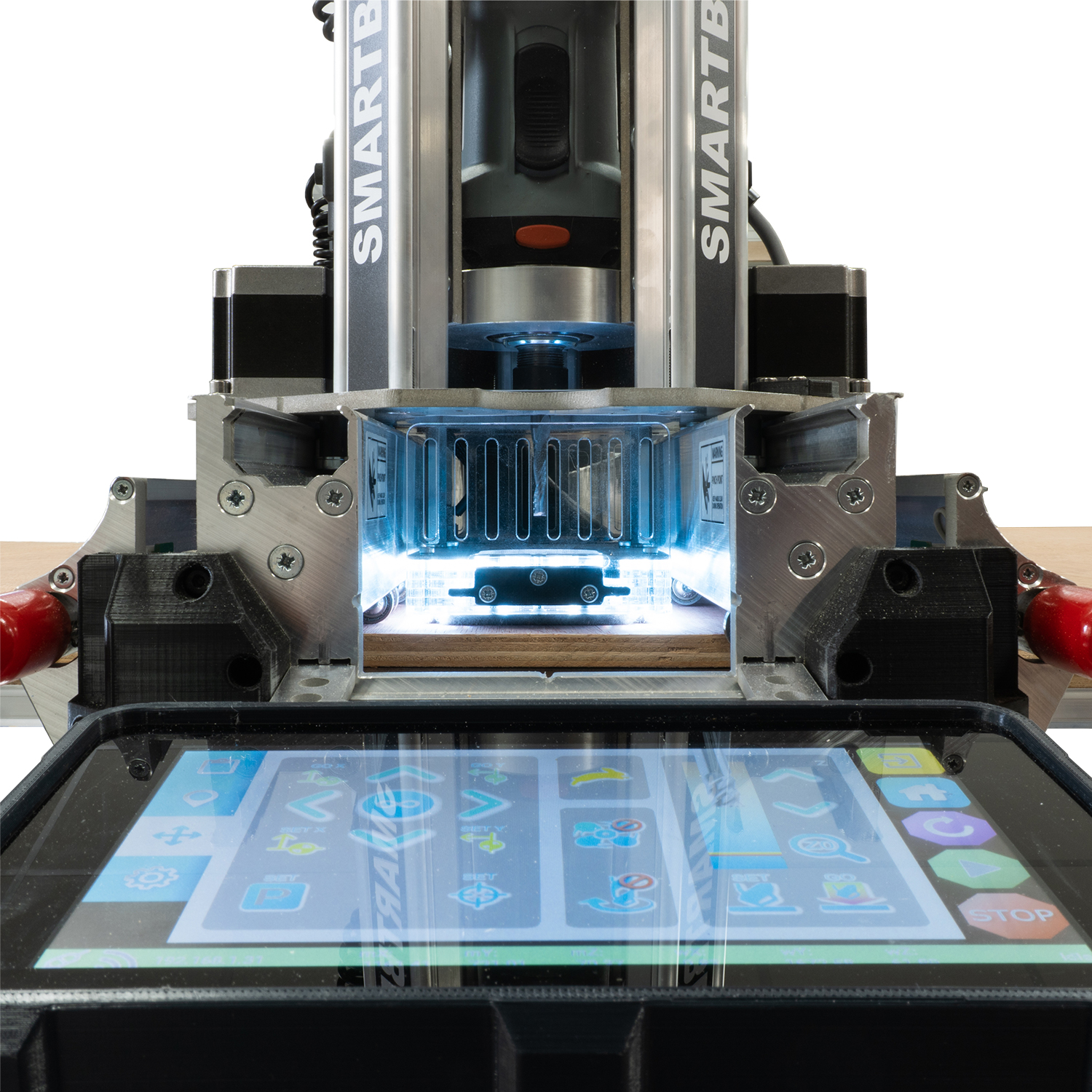

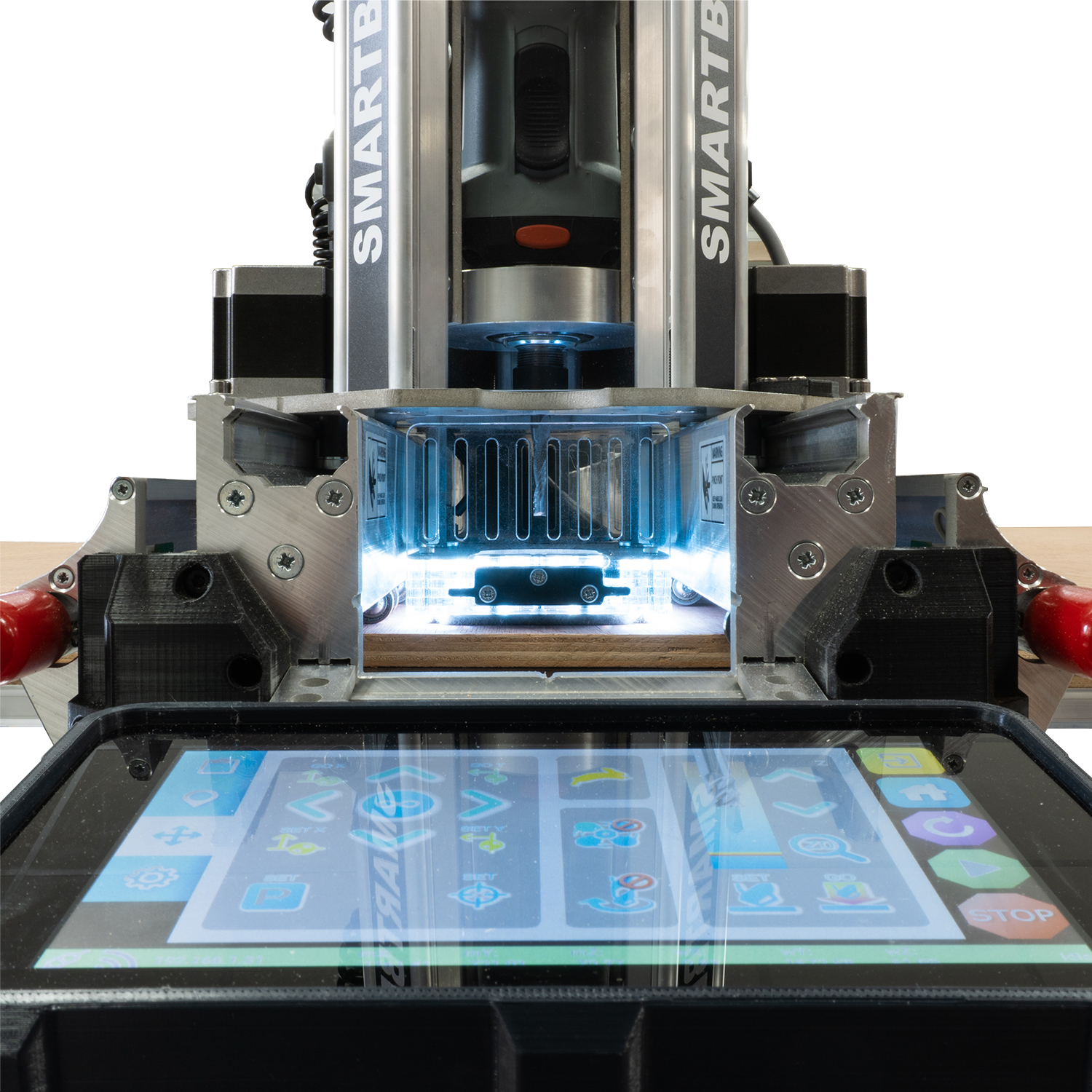

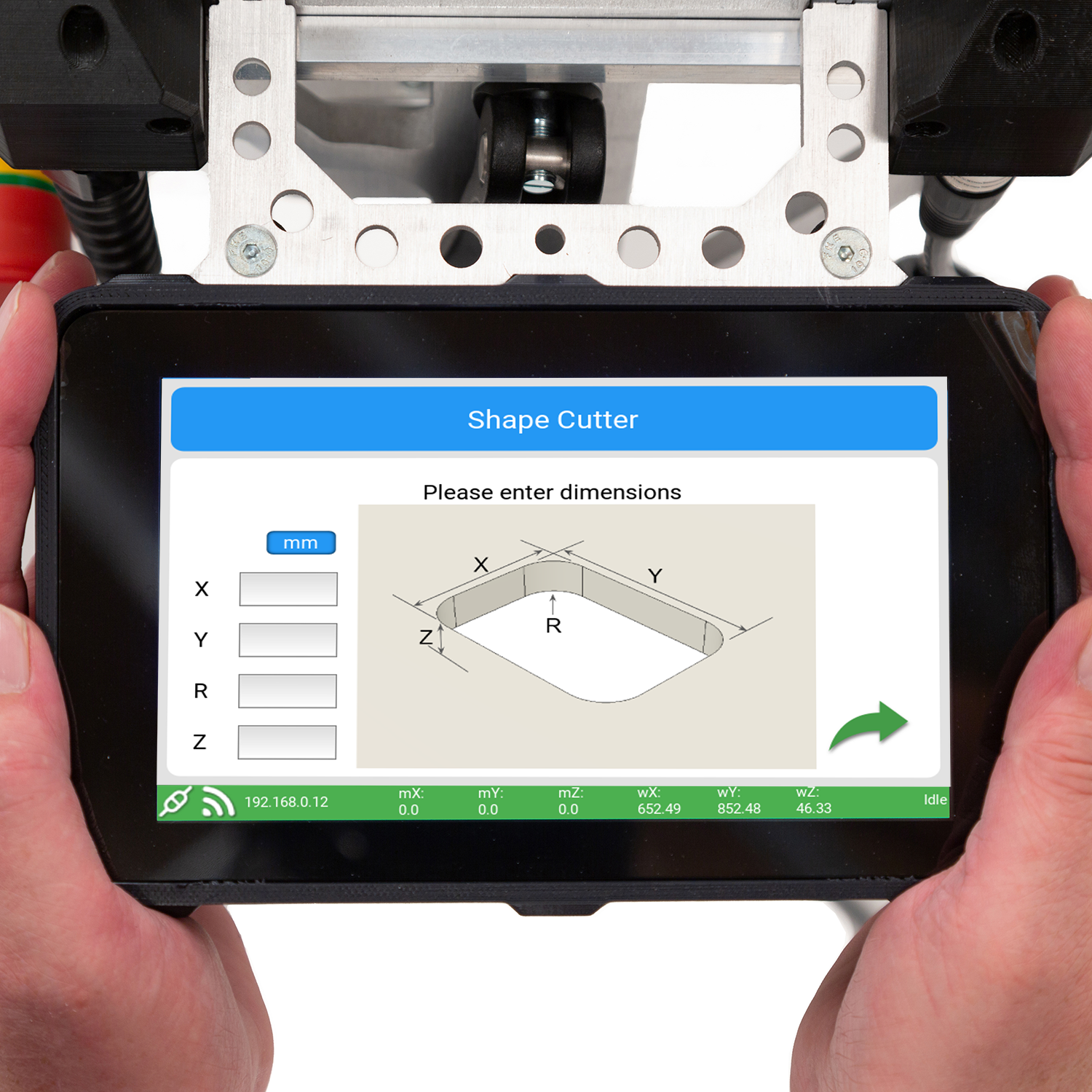

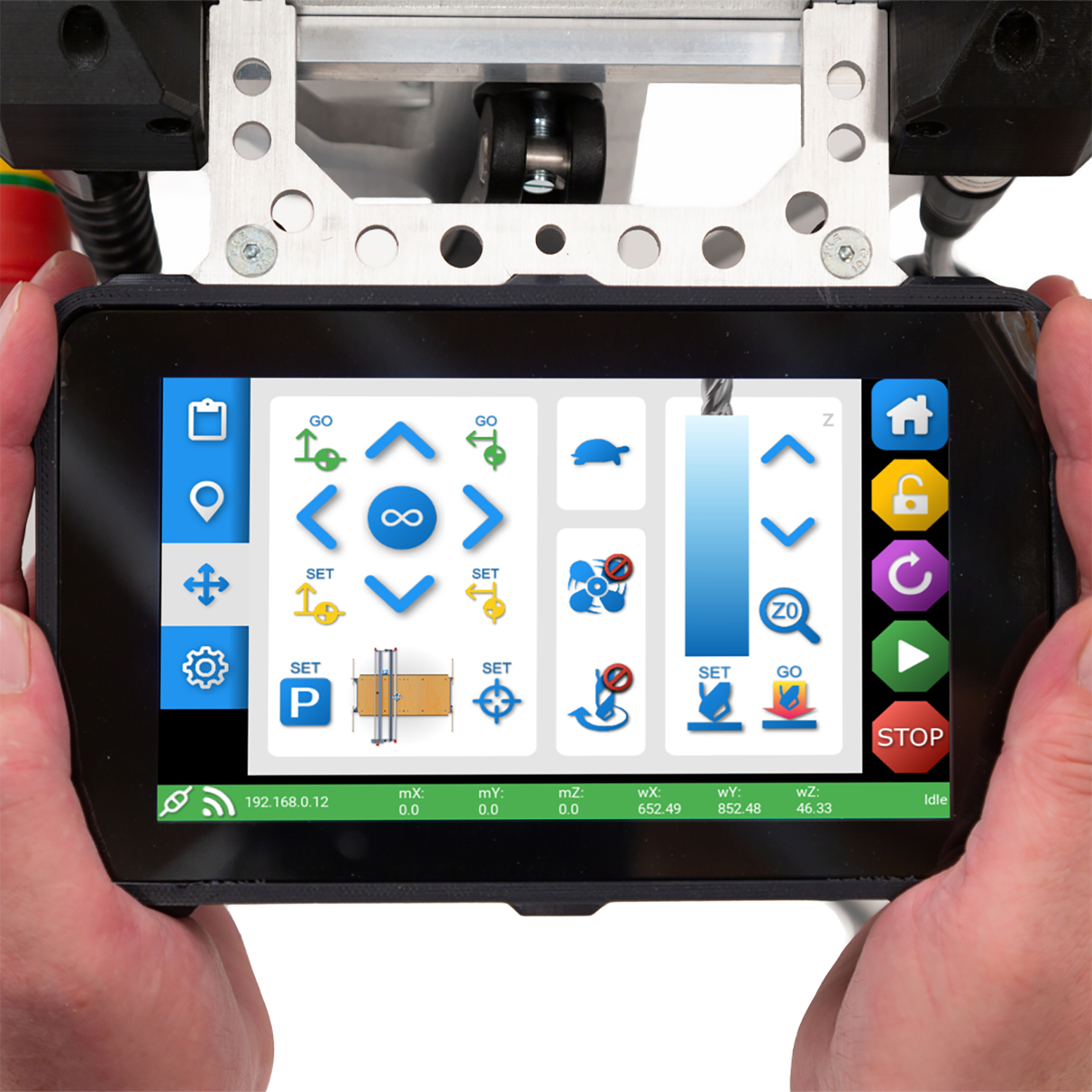

The Shapecutter interface makes it possible to cut simple shapes in an instant directly via the machine’s touch screen.

For more complex files, make your designs on any CAD/CAM software.

Launch the production of your designs with ease thanks to the touch screen and the very intuitive features.

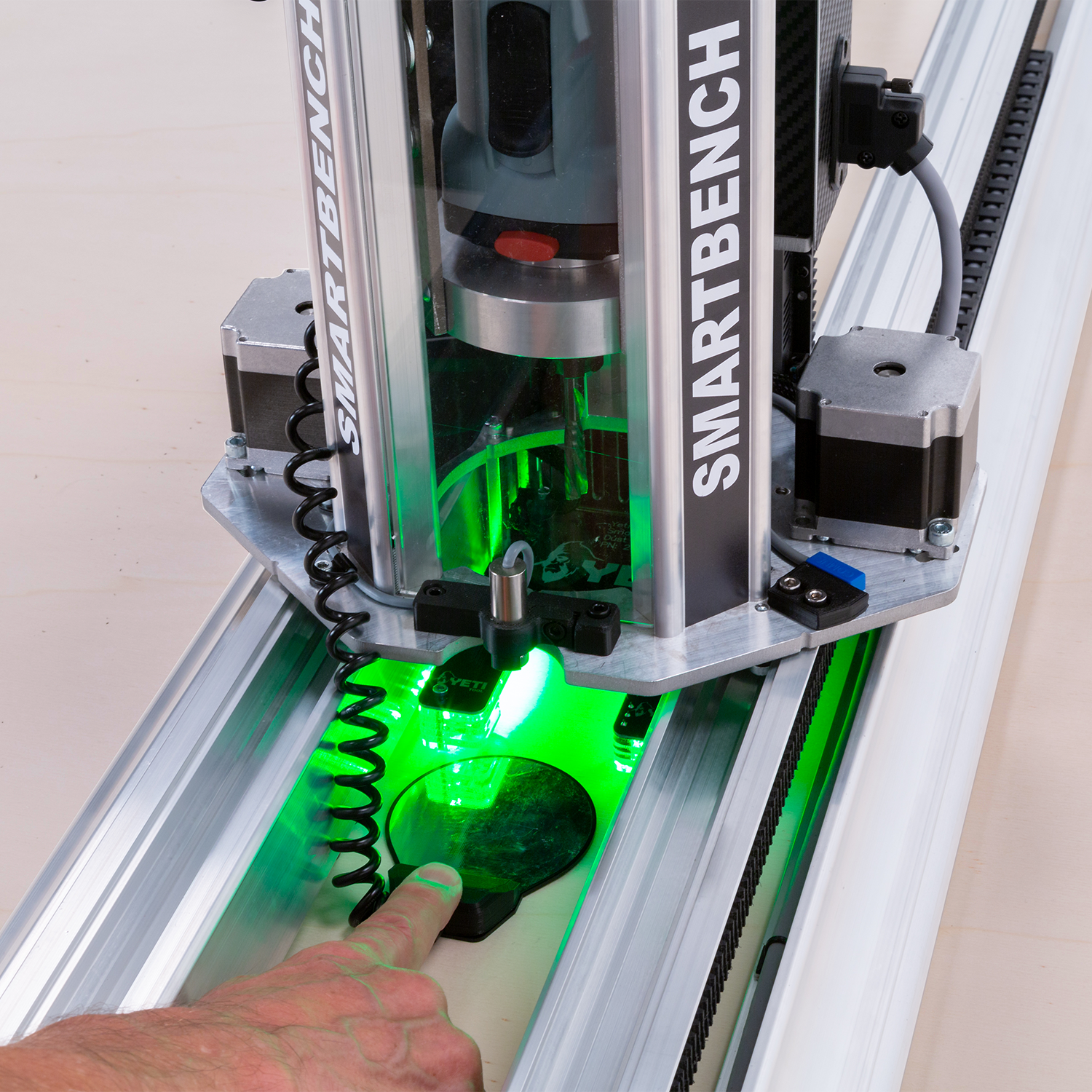

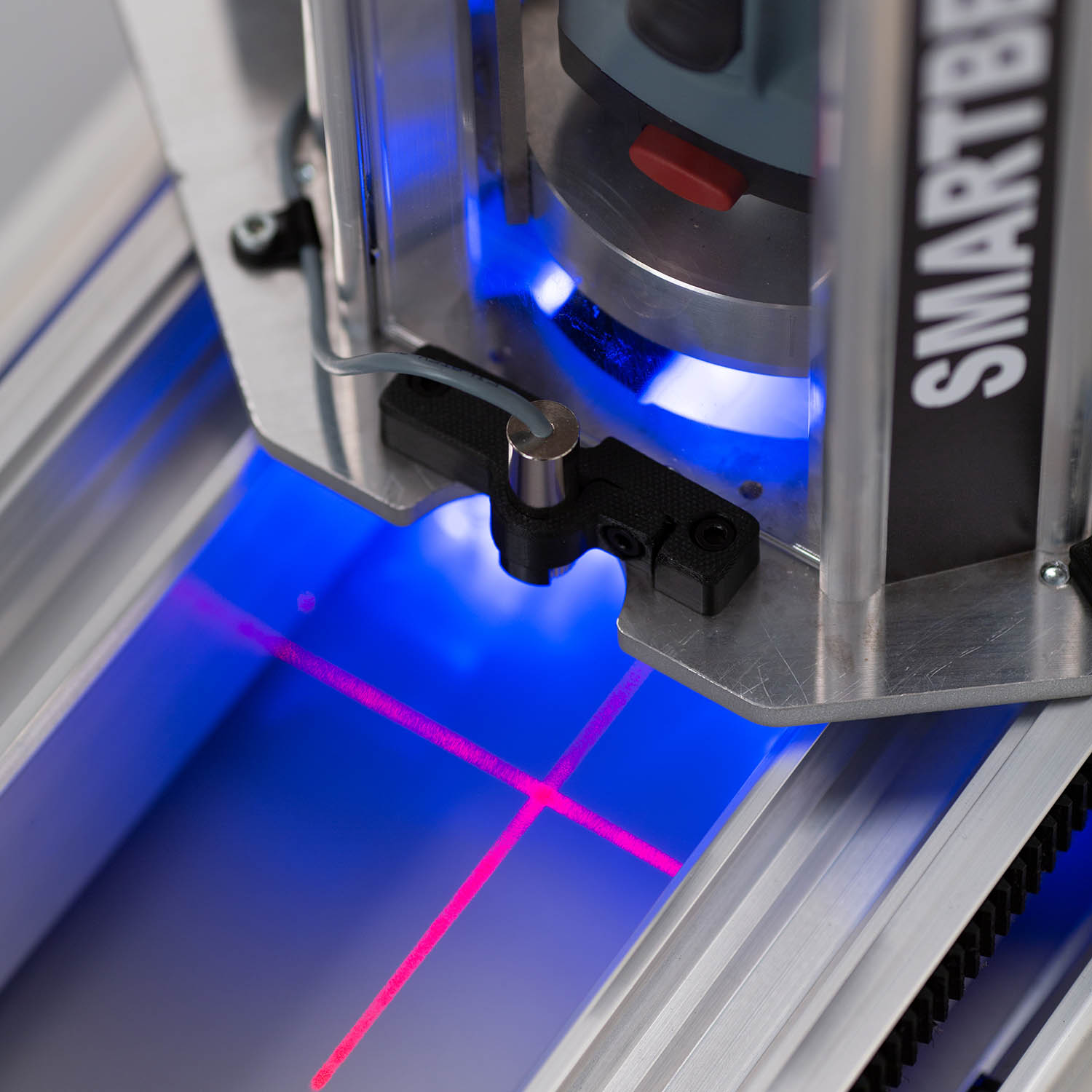

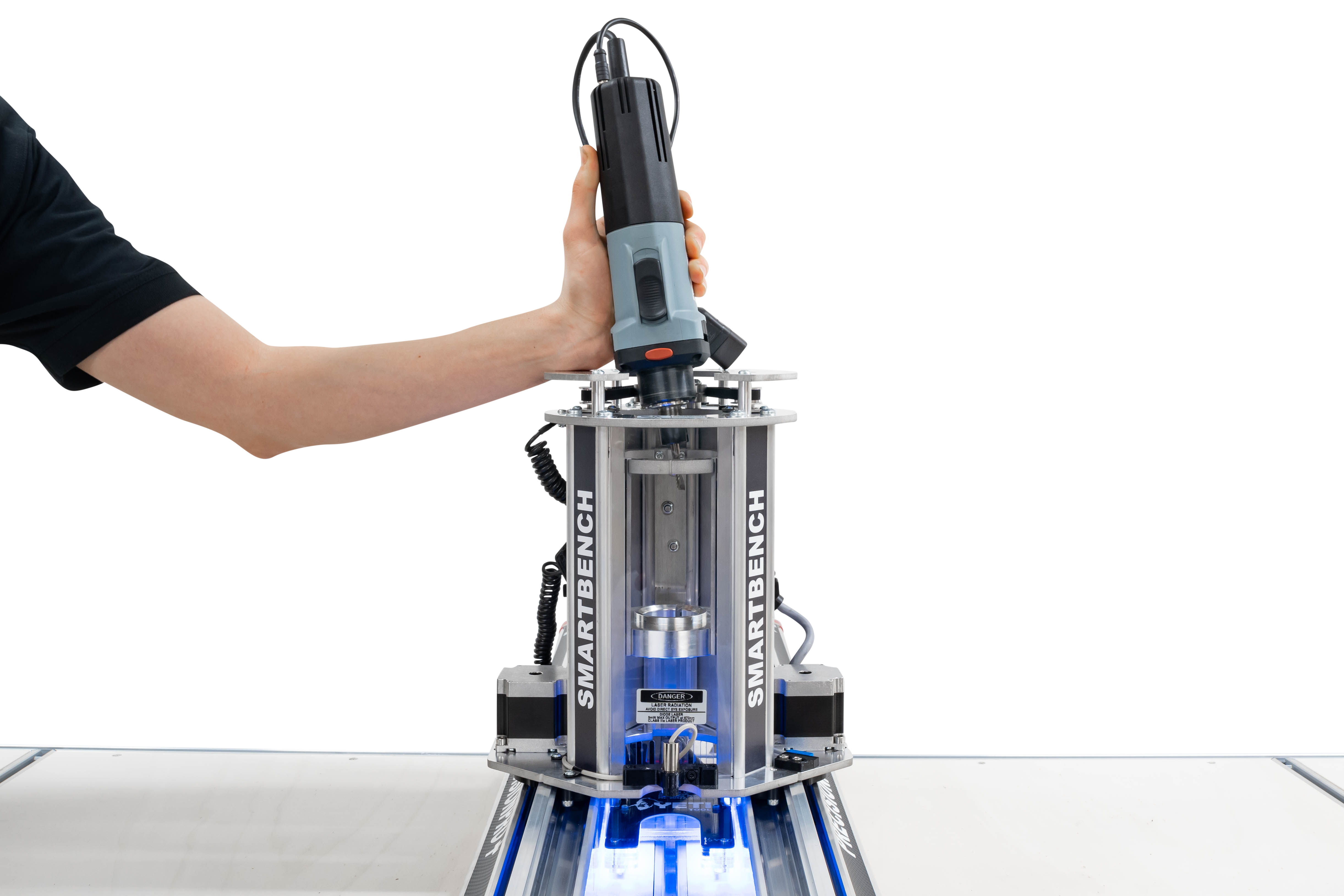

Easily set your XY datum with the laser point and your Z with the built-in Z-probe. All these features allow easy handling for novice users. But it will also delight more experienced users as these functions save time.

Demonstrates the new YetiPilot functionality allowing anyone to get started with CNC in just a few minutes without having to worry about the accuracy of the machining data set, YetiPilot will automatically correct your errors by adapting feedrate.

Best productivuty with Smartbench PrecisionPro+ mini

Focus on other tasks while your Smartbench does the cutting for you. Benefit from increased productivity thanks to the possibility of working on site. During your business trips.

Intelligent adaptive speed machining will save you considerable time, for optimal productivity.

A wide choice of compatible materials

Cut all kinds of materials, so that each project is unique. The Smartbench PrecisionPro+ mini is versatile and will allow you to machine all types of wood (hard or soft), MDF and plywood panels, composite panels (Dibond, Corian, etc.), plastics, (Polycarbonate, PMMA, PVC, etc.) , technical foams (expanded PVC, EVA foam, etc.), and even aluminum (and other soft non-ferrous metals).

And for your safety

The Smartbench PrecisionPro+ mini is compatible with European safety standards. It’s features including emergency stop, interrupt bars along the X axis, vacuum bell and fully enclosed cutter work area as well as spindle retraction in case of anomaly detected by the machine during machining allows users to be safe.

FR

FR