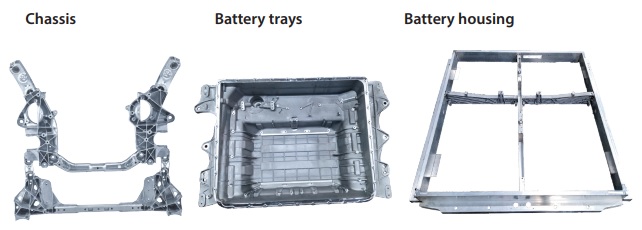

special solution for processing larger workpieces

Special machines for processing of battery trays

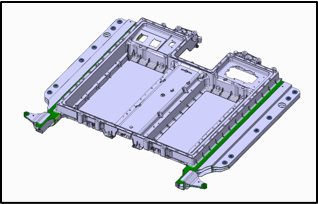

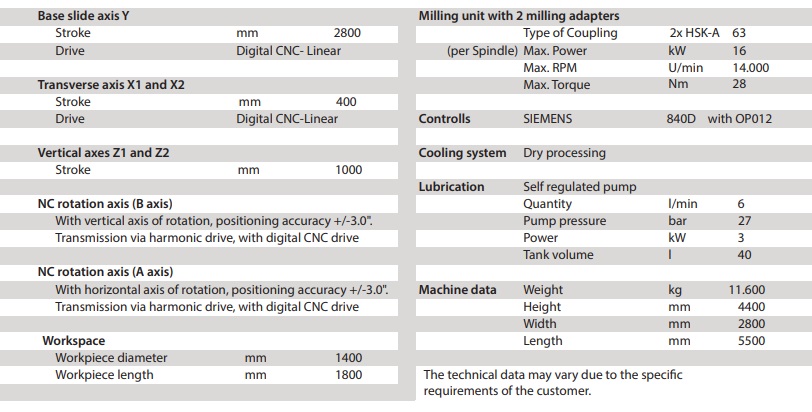

The machine is designed for mass production of workpieces with dimensions 2000 x 1500 mm and more. With two vertical spindles and five independent axes, it enables faster cycle times.

The machine is equipped with a horizontal clamping table mounted on a longitudinal slide – Y-axis with linear drive. The X-axis is mounted on a fixed gantry with two vertical milling axes Z1 and Z2.

On each of the two Z-axes, a special milling spindle is mounted with two tool holders mounted on the vertical rotary axis B and the horizontal axis A.

The milling spindles for face milling and end milling are mounted at 180 degrees on the special spindle and are positioned by rotating the A-axis for the milling operation when in use.

- 4/5-axis processing of the workpiece with 2-spindles

- Dual Spindle simultaneous both sides processing of the workpiece

- Fixed portal with two cross axis with two vertical milling axis

- Design with/-out tool exchange

- Workpiece dimensions from cca. 1700 x 2500 mm

- Robot un-/loading

Special machines for processing of battery tubs

- Special version of the machining centre type Linear for the processing of battery tubs

- Single Spindle 5-axis machining centre

- Workpiece (Battery tub) dimensions: 1100 x 800 mm

- Spindle motor with tool magazine

- Trommel table with NC planets (1-4 planets)

- Linear drive for high-speed processing

- X and Z-axis are driven by the linear motor

FR

FR