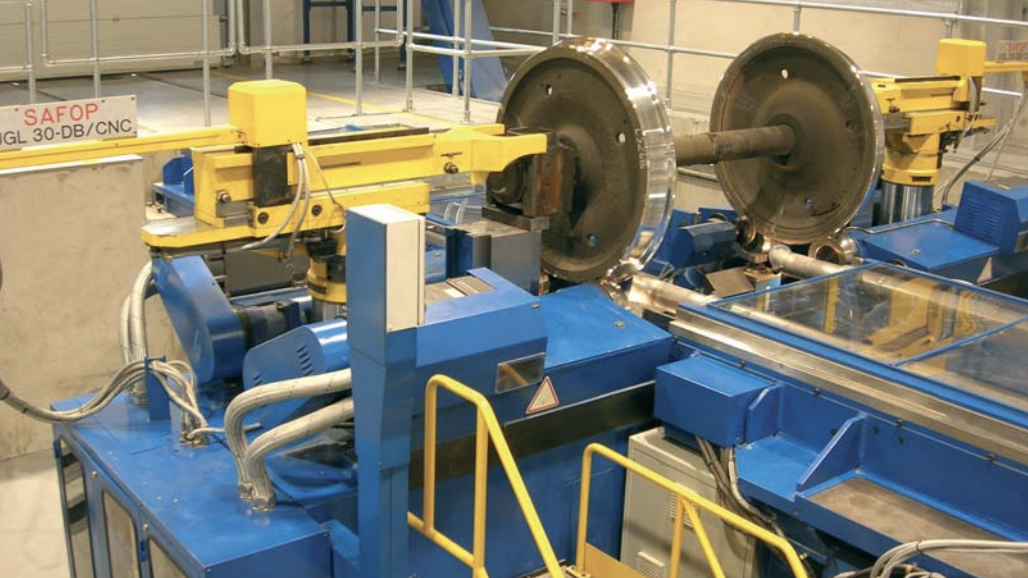

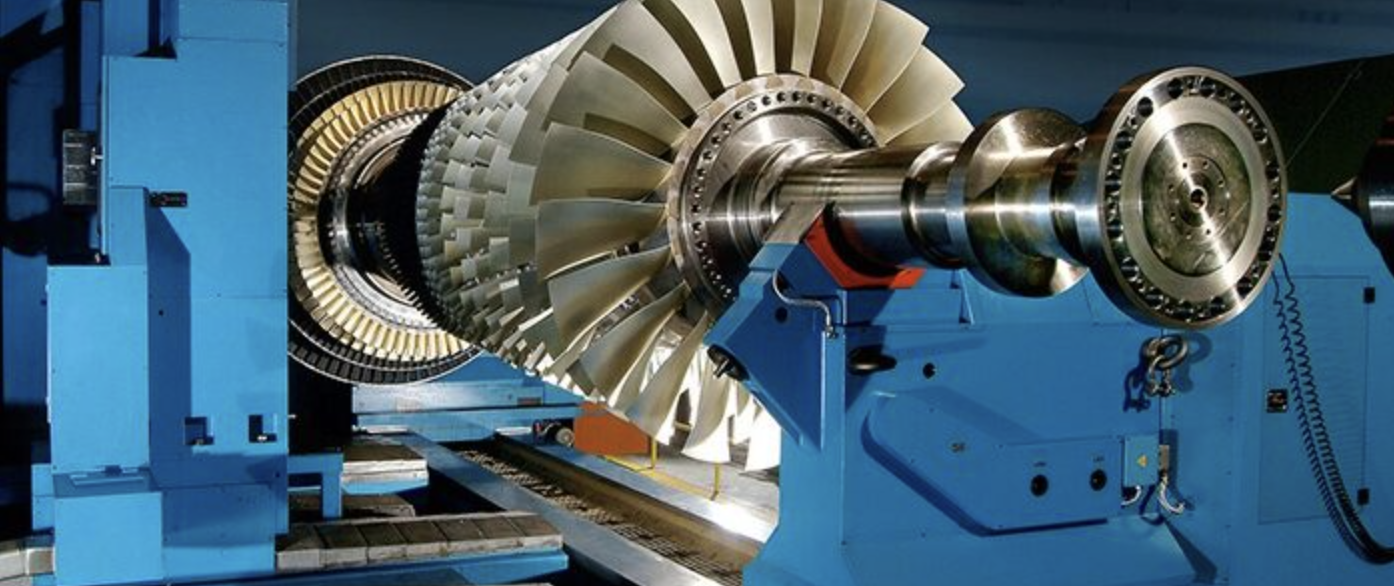

PIT LATHES

Pit lathes play a key role in the maintenance and upkeep of railway wheels and axles. These machines allow for the reprofiling of wheels directly on the train, without the need for full axle disassembly, optimizing the maintenance process and significantly reducing rolling stock downtime. By being integrated into the ground at depots, they enable rapid and efficient maintenance.

Thanks to advanced technology and automated numerical control systems, pit lathes ensure high precision for wheel machining. This allows for the correction of irregular wheel wear and the maintenance of their optimal profile, improving the stability of trains and passenger comfort while reducing rail wear.

Adapted to various types of railway vehicles such as passenger trains, metros, or trams, these machines are versatile and meet the varied needs of operators. Their robust and ergonomic design ensures safe and easy use for operators while complying with the strict safety standards of the railway industry.

In summary, pit lathes offer major benefits: reduced maintenance costs, decreased train downtime, better performance of railway systems, and extended wheel and axle lifespan. They are an essential asset in ensuring a reliable, safe, and high-performance railway network.

Click HERE for more information

FR

FR