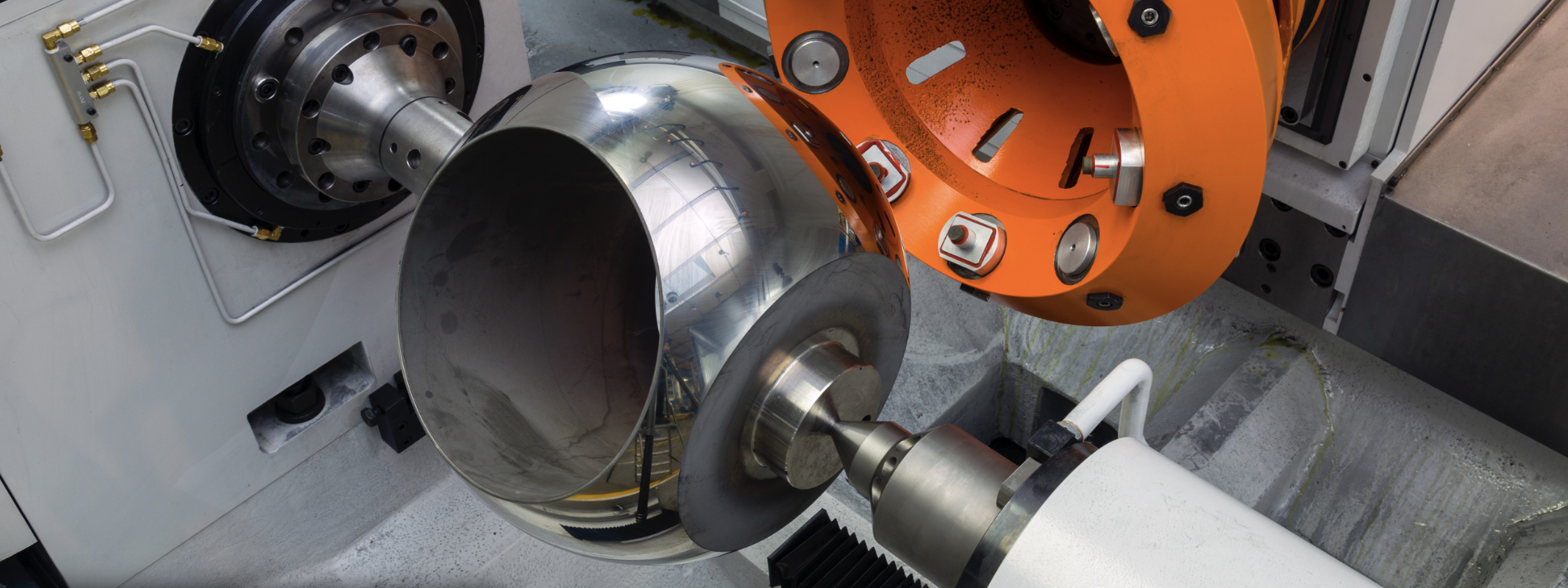

BALL MATIC

The BALL MATIC machine is specifically designed for turning and grinding the spherical bodies of valves. This high-precision tool is used for machining ball valves with a working range of 2 to 64 inches, making it an essential piece of equipment for industries requiring rigorous control of spherical geometry.

KEY ADVANTAGES

High Precision:

- Spherical grinding ensures perfect sealing and optimal fit of valves in industrial applications.

- Minimal achievable tolerances allow for strict control of part geometry.

Versatility:

- Suitable for parts of various sizes thanks to its extended machining range.

- Capable of handling different materials, from steel alloys to more specialized materials used for high-performance valves.

Wide Range of Industrial Applications:

- Used in sectors such as energy (oil and gas), hydraulic infrastructure, and chemical industries, where spherical valves play a key role.

Time and Efficiency Gains:

- Combining turning and grinding operations into a single machine reduces cycle times and boosts productivity.

INDUSTRIAL APPLICATIONS

•Oil and Gas Industry: Machining valves used in pipelines and offshore installations.

•Chemical Industry: Manufacturing corrosion-resistant valves for harsh environments.

•Water and Energy: Valves used in water distribution systems or power plants.

•Nuclear Industry: Producing high-performance valves that meet strict safety standards.

Click HERE for more information.

FR

FR