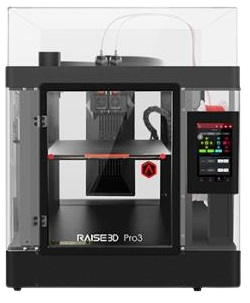

Raise3D Pro3

Raise3D’s dual extruder 3D printers meet the needs of both production and multi-sized rapid prototyping, with high precision and round-the-clock stable operation. It fulfils the requirements of large-scale production and multi-sized rapid prototyping. A high-quality printer design that includes enhanced features and a smart assistant system known as EVE, all of which make the Pro3 Series dual extruder 3D printers an excellent option for professional 3D printing.

Enhanced Printing Platform Features

The Pro3 Series features upgraded printing platform features for high-quality printing performance and a better overall experience. The auto bed leveling makes setting up a 3D printer quicker and simpler. The flexible build plate allows for the effortless removal of 3D printed parts.

The Z-axis rod stiffness increased by 75% to deliver a more stable performance. These structural changes enable the Pro3 Series to provide better print results and an easier printing experience.

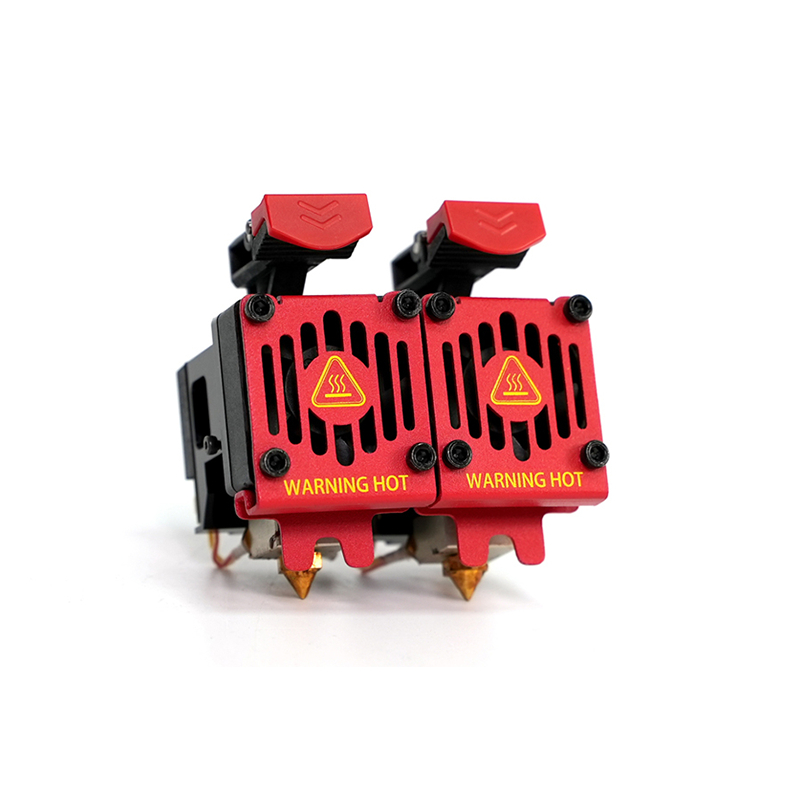

Detachable Hot End and Extruder Cover

The Pro3 Series is equipped with an independent modular extruder with a dual extrusion system. This allows the Pro3 Series to print using a variety of filaments, reduce clogging, and allow convenient disassembly and replacement of components. The hot end of the Pro3 Series is easy to remove, which can be done without using tools, facilitating the replacement and maintenance of the hot end. Users can also easily take off the front cover of the extruder to accurately locate common printing impediments such as filament jams.

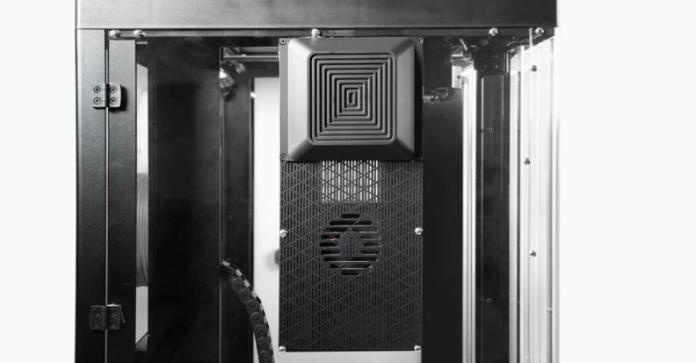

Air Flow Manager for Better Heat Dissipation

The Air Flow Manager of the Pro3 Series is located on the back of the printer, improving heat dissipation and air circulation, creating a stable environment inside the print chamber. Equipped with a HEPA air filter, Air Flow Manager can also filter and clean the air inside the chamber.

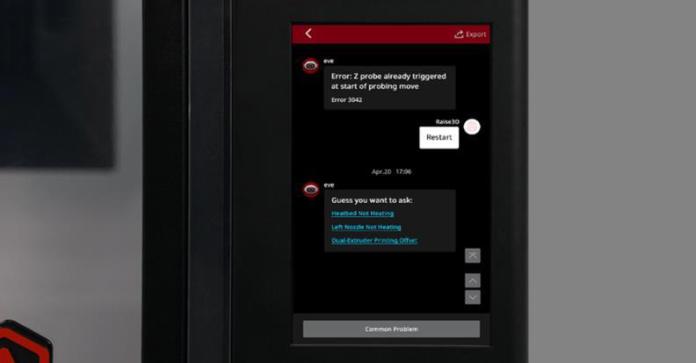

EVE Smart Assistant

The Pro3 Series has a built-in EVE assistant system, preloaded with common printing problems and corresponding solutions. The EVE assistant can guide users to accurately locate and resolve issues that could affect the final print job. The EVE assistant has a function that gives users reminders about regular scheduled interventions to ensure that printer maintenance is performed on time. It also helps reduce maintenance time and communication costs for an efficient maintenance process.

Lightweight Cable with Digital Temperature Measurement

The Pro3 Series replaces the drag chain cable with a lightweight cable, to reduce the weight of the extruder and keep the center of gravity in the middle during printing for more stable print quality.The Pro3 Series also uses digital temperature measurement, for an accurate temperature reading to help prevent jamming

The importance of Auto Bed Leveling

Bed leveling is the process of confirming that the printing platform is as level as possible. The Pro3 Series has this leveling procedure as an automated function. Auto bed leveling will maintain the distance between the print nozzles and the bed, to create a uniform build area. This improves bed adhesion and allows the nozzle to adjust to even the most minor surface contour changes

HD Camera, Eligible for Upgrade

The Pro3 Series uses a HD camera to monitor the entire 3D printing process of every print job. This camera operates by connecting to RaiseCloud, allowing users to keep track of every print job remotely and while on the move. This ability to check the 3D printing process gives peace of mind. The Pro3 Series also comes with an upgraded CMOS sensor to ensure better image quality

Automatic Detection

A safety feature of the Pro3 Series is that it can automatically detect when a door is opened and will immediately pause the print.

KIT HYPER SPEED

An innovation for FDM / FFF 3D printing technology allowing a gain in productivity thanks to a printing speed approximately 3.5 times faster. This upgrade kit for the famous Pro3 and Pro3+ from Raise3D makes it possible to combine speed, precision and fluidity, for ever more qualitative parts, in record time.

Increase productivity without compromising quality

Print 600 to 1000 grams of filament in 24 hours with the prowess of Raise3D’s Hyper Speed upgrade Kit.

Combine the print quality of the Pro 3 series with the increased speed of the Hyper Speed kit, allowing you to achieve a print speed of 200 to 350mm/s against 50 to 80mm/s for equivalent competing printers, and a speed of acceleration up to 10000mm/s.

Contents of the kit :

- Two 0.4 mm Hyper Speed hotends

- A Hyper Speed automatic calibration head

- A spool of PLA Hyper Speed filament (white, 1 kg and 1.75 mm)

- A spool of Hyper Speed ABS filament (natural, 1kg and 1.75 mm)

- The Kit activation code

- Software upgrades

FR

FR