Print 150 Family METAL 3D PRINTERs

3 machines 1 platform

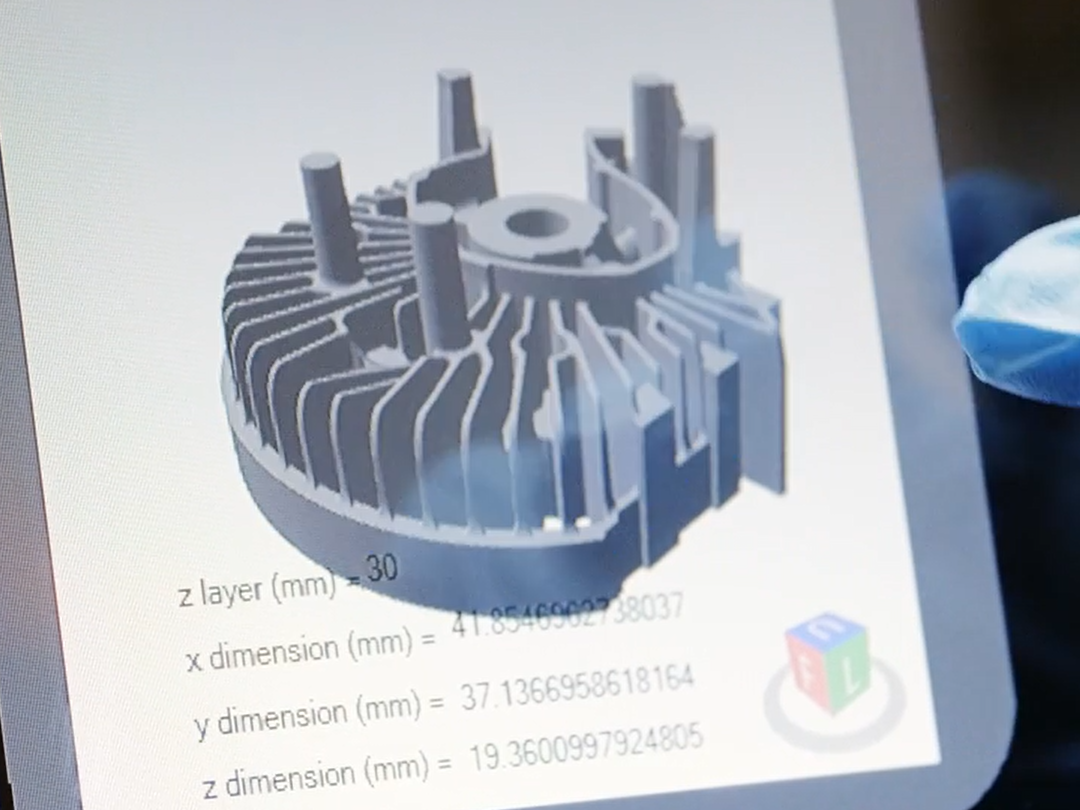

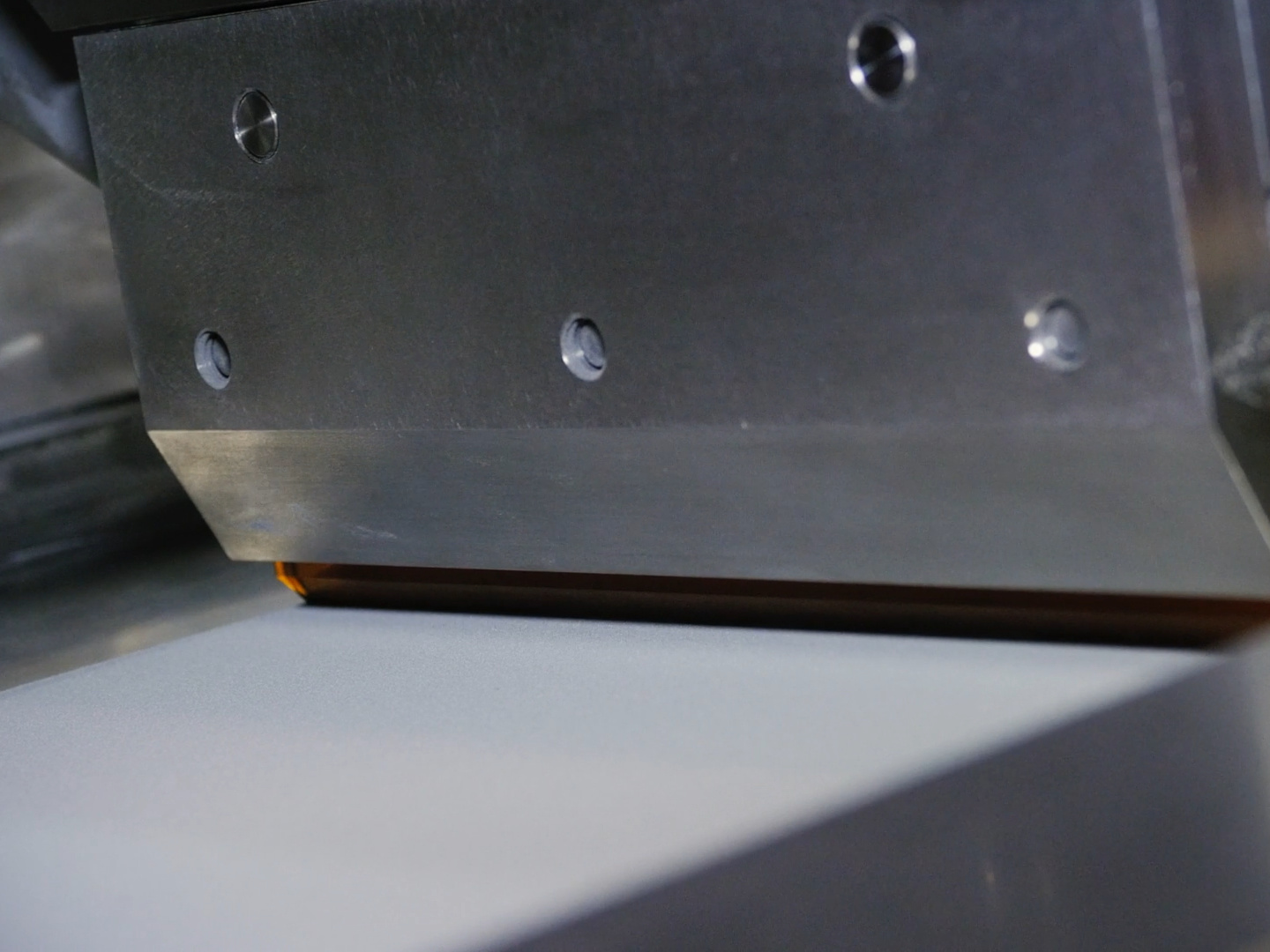

The Print 150 serie are Powder Bed Fusion machines whith an innovative open-configuration powder bed additive system consisting of a cylindrical working area, a preheating system, real-time monitoring of process parameters and a laser spot. A compact additive manufacturing machine with a building volume of Ø150mm and H = 160mm for manufacturing small components.

The system has optimised gas flow for minimum nitrogen or argon consumption and material can be changed in less than two hours thanks to modular components.

With the ability to customise process parameters, Print Sharp 150 is also ideal for those looking for a machine with which to research new materials.

Efficient machines

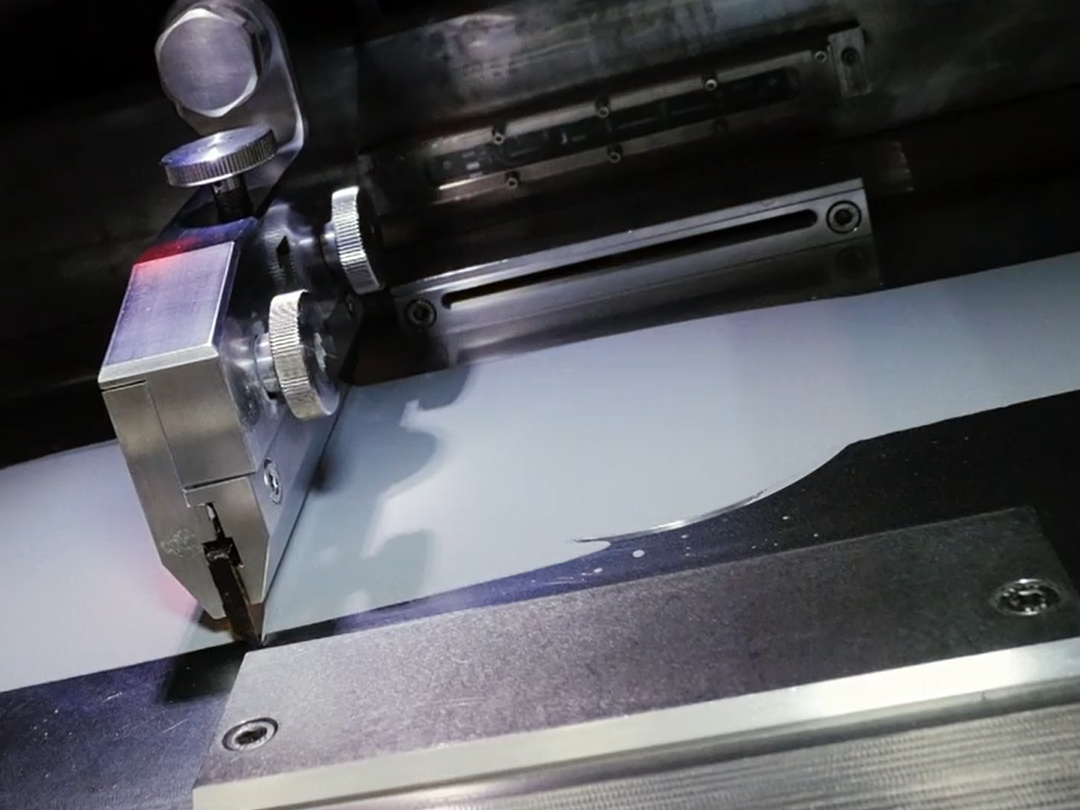

Print Sharp 150 is equipped with a 300W single mode IR fibre laser source (depending on configuration). The laser source is air-cooled, so no external unit cooler is required.

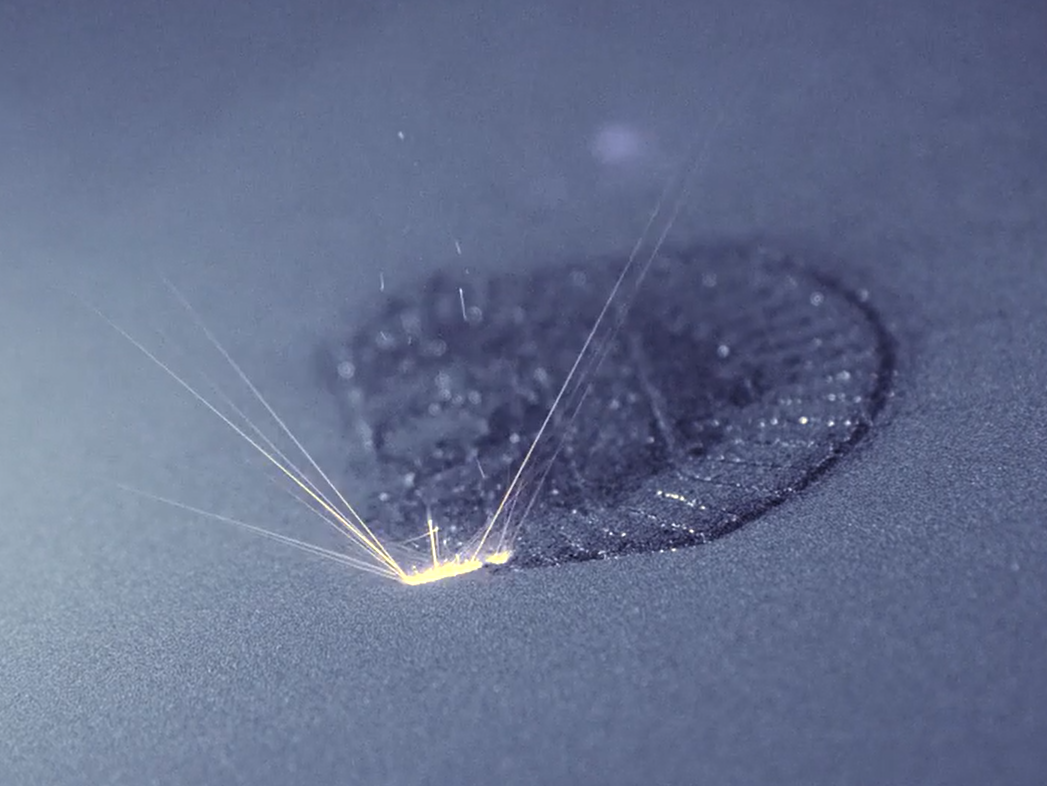

A single line width of 0.1mm and a minimum layer thickness of 0.02mm can be achieved for high precision. A reliable and compact optical scanning system offers high processing speeds and various scanning strategies.

The system is equipped with a filter unit for recirculating gas within the working area. The filter unit maintains a high level of cleanliness and is easily adjustable thanks to the control installed on the interface. Gas flow within the chamber can be modified to optimise flow as required.

Preheating the top and bottom of the powder bed to 300°C to ensure the best melting performance.

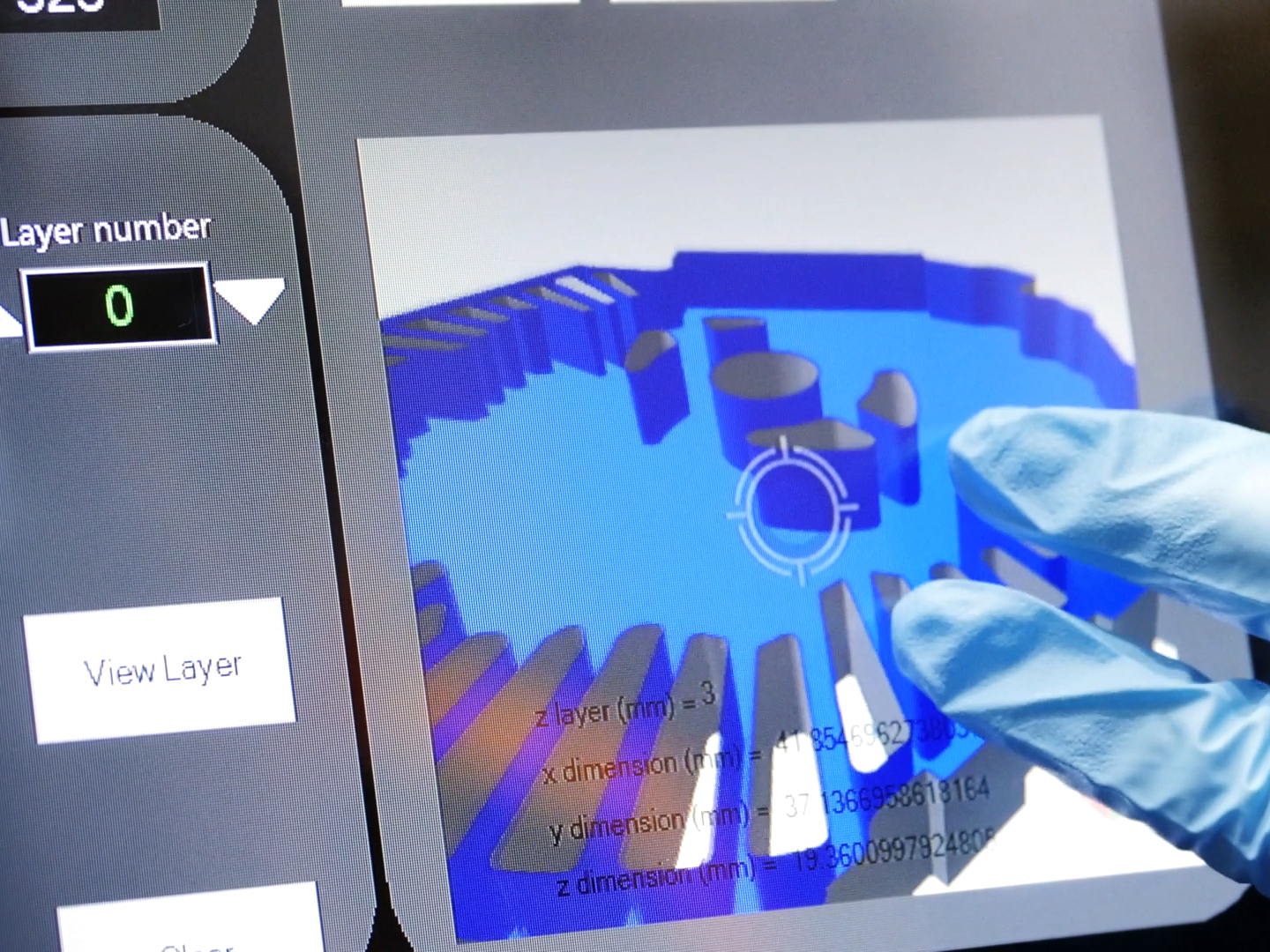

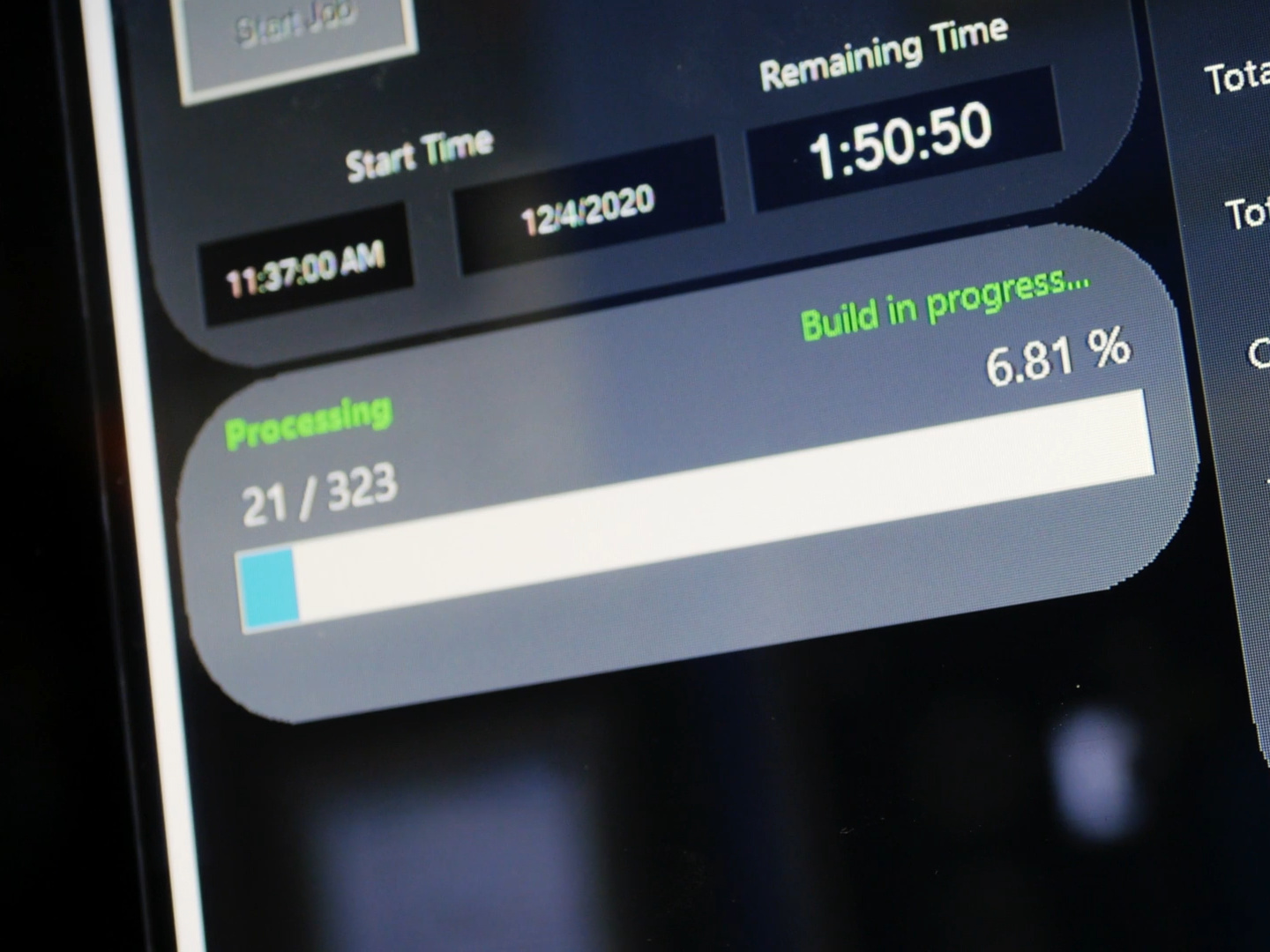

Easy to use and efficient software

Intuitive, intelligent control software allows rapid orientation of parts and defining of machine functions by the operator. With an open, easy-to-use process parameter management tool, you can also change key print parameters, select your scanning strategy and export machine-readable files.

FR

FR