Laser Next 2141 METAL 3D PRINTER

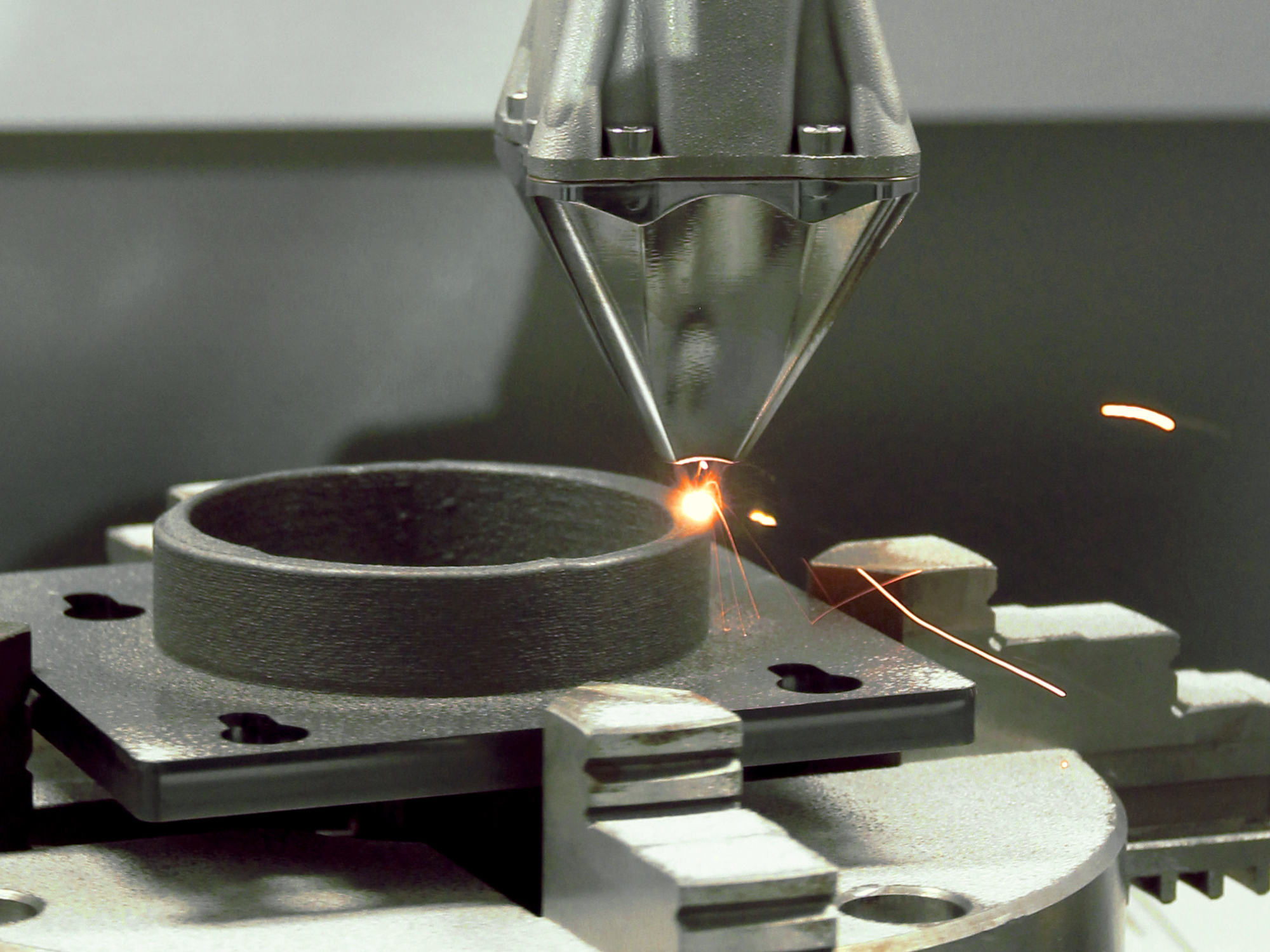

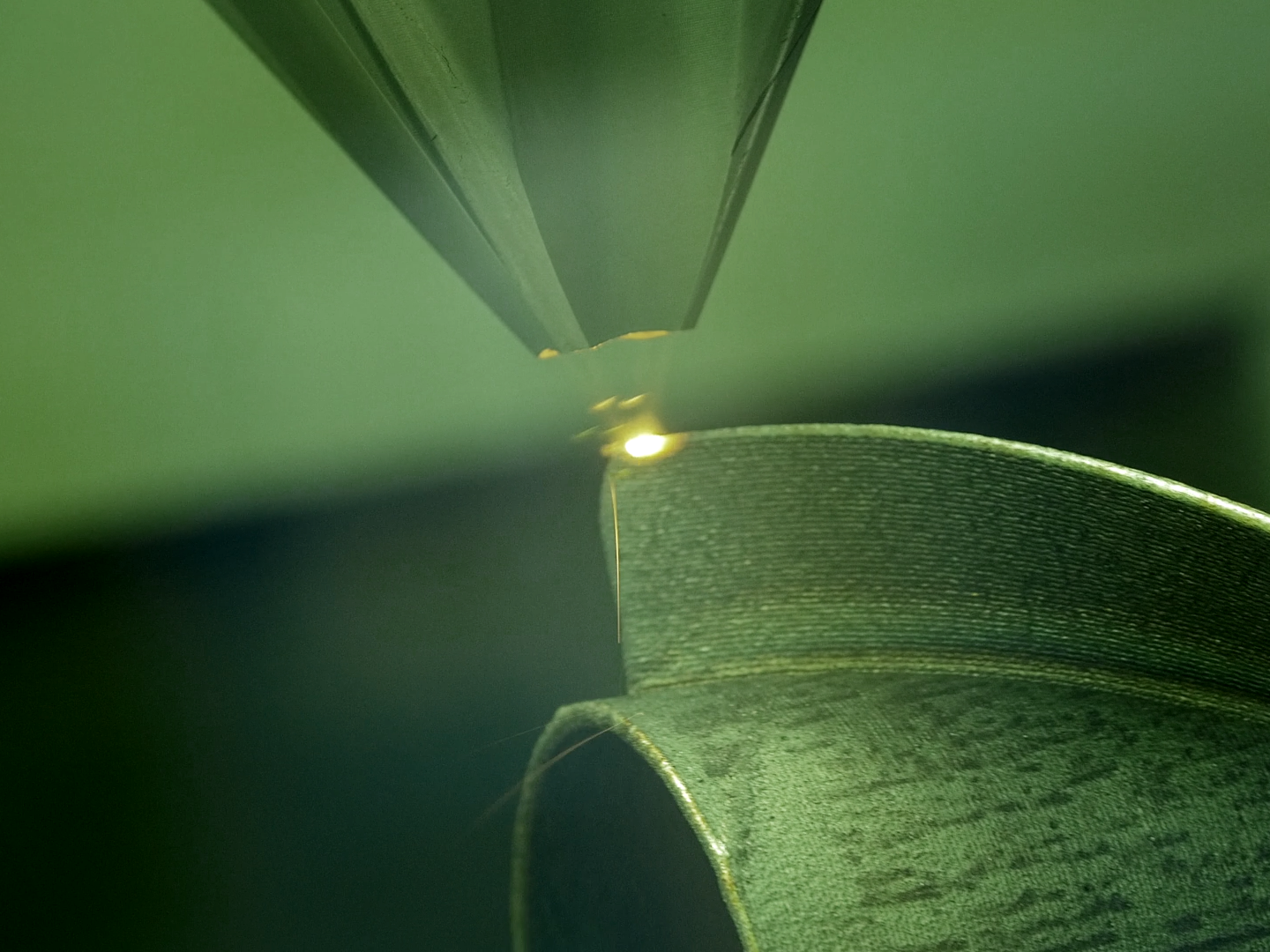

Laser Next 2141 with Direct Energy Deposition technology is based on a laser metal deposition process.

The most versatile platform available today for direct deposition additive manufacturing.

The system can handle both large and small parts and is suitable for repairs, reworking and coating.

The 5-axis platform is particularly suitable for all sectors that require movement flexibility and high precision.

Thanks to Prima Additive’s Direct Energy Deposition technology, the powder deposited on the component is melted where it is needed by a deposition head that moves along 3 to 5 axes simultaneously.

5-axis motion with CNC control and full CAM suite

5-axis CNC system with integrated multiple crash protection, easy access and loading position. The addition of a tilting rotary table increases the machine’s flexibility by providing the system with two additional axes for more complex applications.

Suitable for many use

Can be used for parts manufacturing and reworking in a wide range of materials

Taking advantage of the workspace and easy installation, Prima Additive’s largest Direct Energy Deposition machine can be used for complex repairs and reworking.

FR

FR