ONE CLICK METAL

– BOLD Series – MPrint & MPure

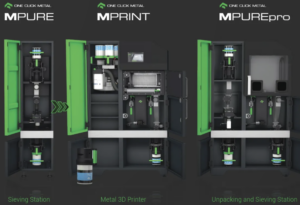

The BOLDSERIES, developed by One Click Metal, represents a holistic and user-friendly metal 3D printing system. At One Click Metal, the overarching goal is to simplify the complexity of metal additive manufacturing technology, making it accessible and understandable for everyone. With this goal in mind, the BOLDSERIES focuses on affordability and ease of use, while ensuring high-quality parts. Key features such as the cartridge system and the intuitive step-by-step HMI support this philosophy by enhancing user experience and simplifying operations.

The BOLDSERIES, comprises several components:

- The MPRINT, a metal 3D printer that forms the core of the system.

- The MPUREpro, a 2-in-1 unpacking and sieving station that streamlines post-processing steps.

- The MONE, a digital platform for location-independent monitoring and control of the M-PRINT.

- The MPURE, a sieving station, available as an alternative option if sieving is regional within the BOLD SERIES

M-PRINT

The MPRINT is the printing unit of the BOLDSERIES. Powered by a 200W fiber laser, it offers high productivity and precision across a wide range of applications. The MPRINT features a cartridge system that ensures the safe and clean handling of powder, minimizing direct contact for the user. Especially in the educational sector and in small enterprises the limited contact with powder is an important key feature of the BOLDSERIES.

With a generous build volume of 150mm x 150mm x 150mm, the MPRINT provides ample space for creating components with flexible designs.

The user-friendly interface of the MPRINT guides users through each step of the printing process, facilitating the creation of high-quality printed components with ease.

MPUREpro

The MPUREpro serves as the unpacking and sieving device within the BOLDSERIES. Once the printing process is complete, the entire build cylinder can be transferred into the dedicated unpacking chamber of the MPUREpro, guaranteeing a secure depowdering process. The unpacking chamber is hermetically enclosed and functions as a glove box during the depowdering. The excess powder around the printed parts is efficiently collected within an overflow cartridge

without direct powder contact to the operator, ready for further processing in the integrated sieving station. Through the automated ultrasonic sieve, the powder is carefully prepared for future printing jobs. By utilizing our cartridge system, direct user contact with the powder is minimized, prioritizing user safety and risk reduction. Our innovative approach does not only protect the end user but also guarantees that the powder is securely sealed within the cartridges, ensuring its optimal condition.

- Generously dimensioned glove box in the unpacking chamber allows safe bulk powder removal

- Integrated connection for external vacuum system reduces initial investment cost

- Patented supply and overflow cartridges ensure safe and simplified powder handling

- Fully automatic sieving process, simplifying the workflow and reducing manual intervention

MPURE

You already have a solution for depowdering and you only want a sieving station? Then the MPURE is the right device: The MPURE is focusing only on the sieving of processed powder. It utilizes an ultra-sonic sieve to carefully prepare the powder collected from the overflow cartridge. This sieving process helps remove any impurities, ensuring that the powder is clean and ready for reuse in the next printing job. The sieved powder is automatically transferred into a fresh supply cartridge, making it effortless convenient for future printing operations. With its minimal form factor it fits next to the MPRINT in any workshop.

FR

FR