CYCLONE

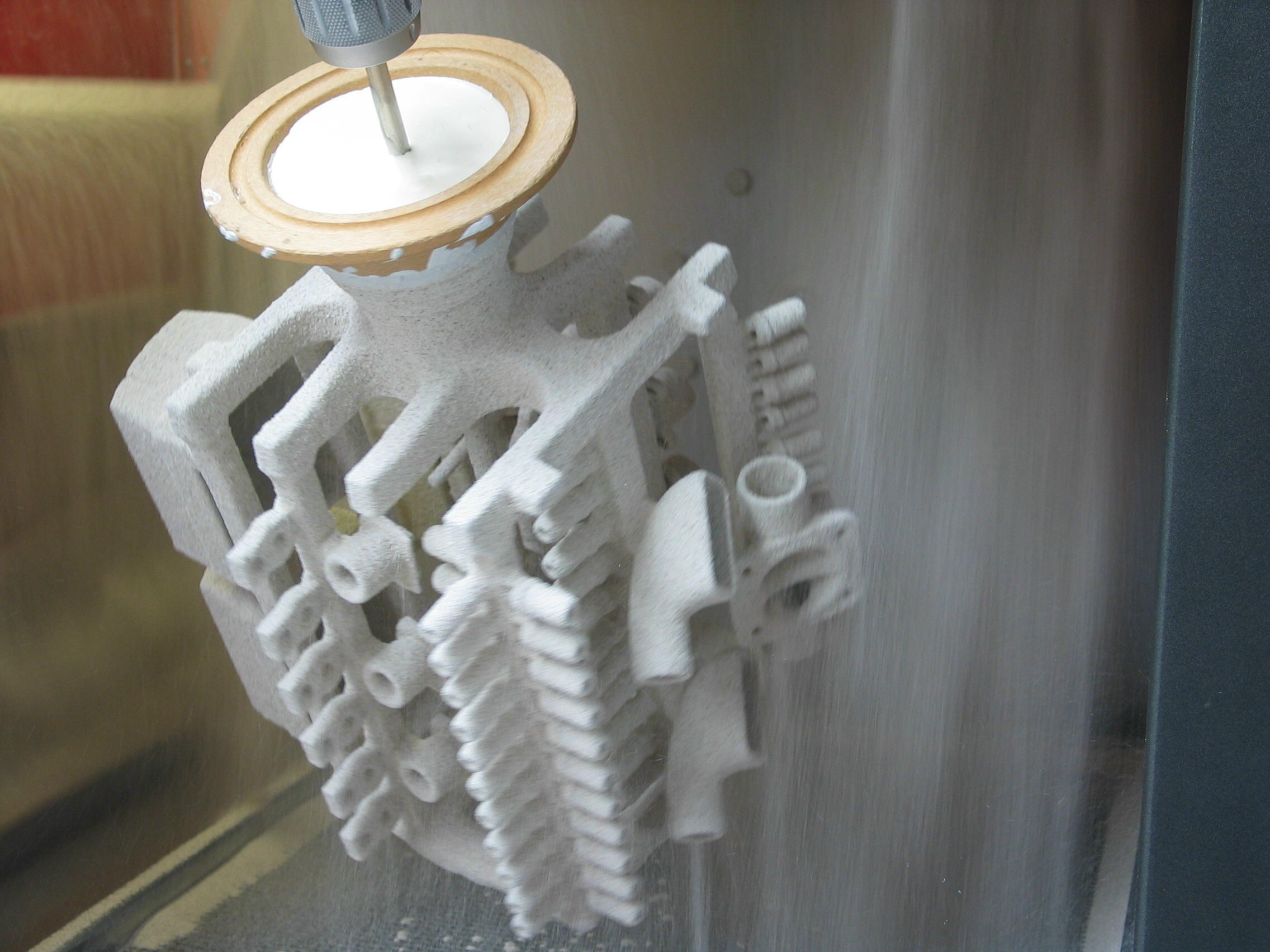

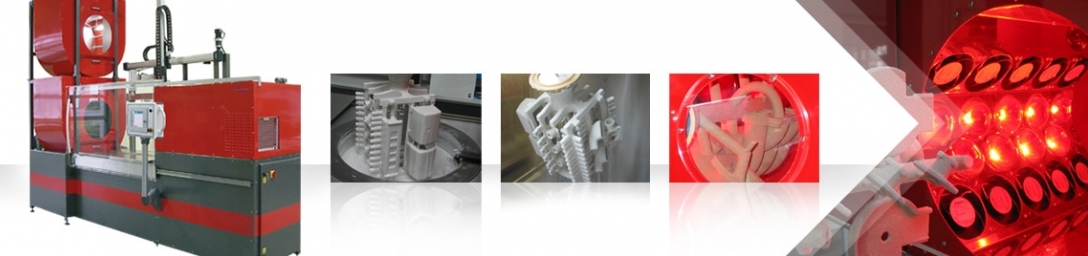

The MK Cyclone is a complete shell building factory requiring very little space. It consists of two rotating slurry tanks (for primary and back up slurry), two or three (optional) rainfall sanders and the high speed drying chamber. A linear robot moves the tree from one station to the other and a shell with 7 layers can be produced within 4 hours without supervision. The optional automatic wax tree magazine enables the user to produce up to five shells in a row.

The Cyclone consists

- 2 slurry tanks

- 2 rainfall sanders (optionally a 3rd one)

- Linear drive – 4 axis

- PLC control, control panel and display

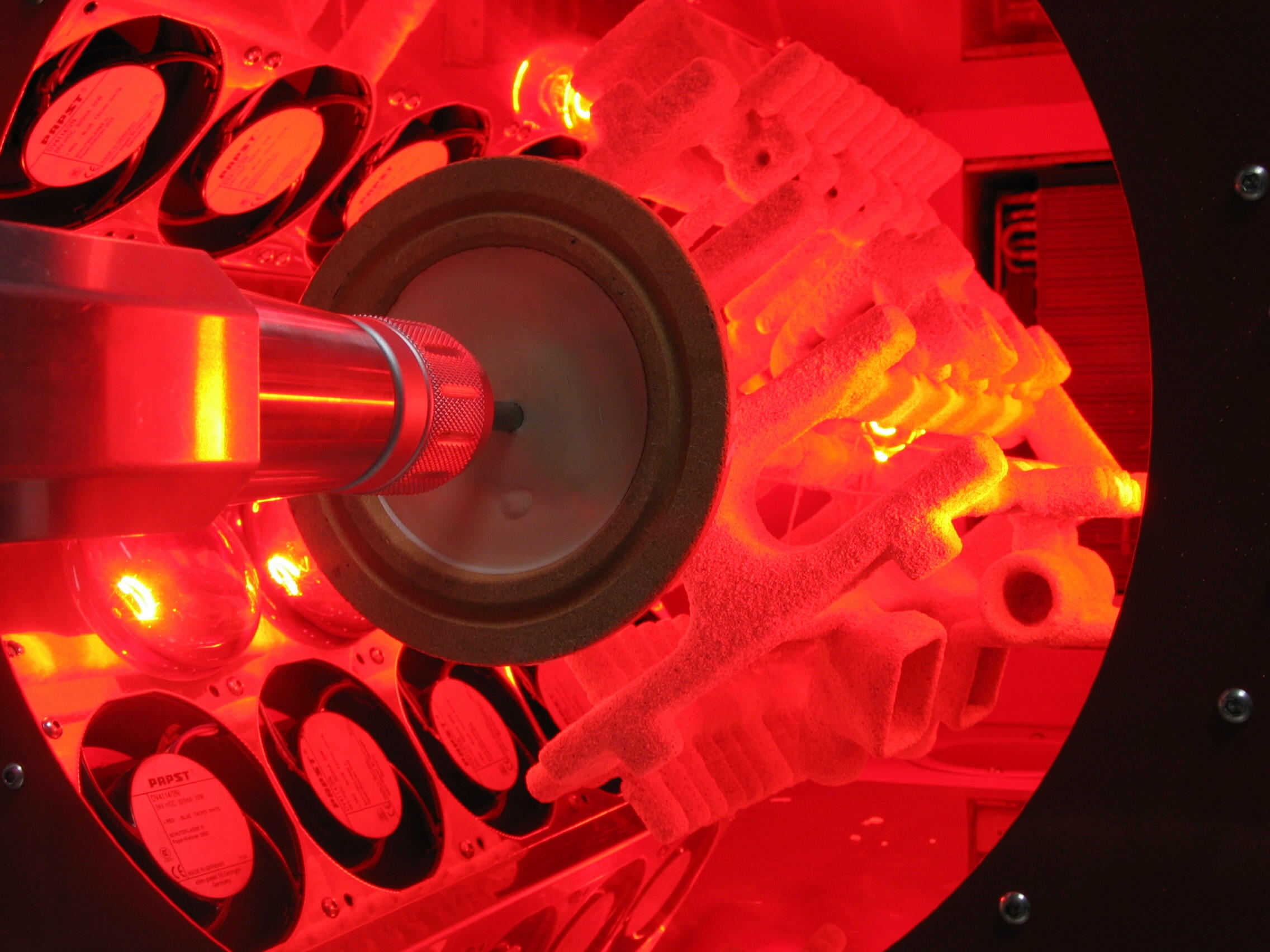

- High-speed drying chamber

- 3 x automatic door systems

- Integrated dust ventilation

- Optional automatic wax tree magazine

The Cyclone is the first machine for producing a complete shell at the push of a button in less than 4 hours. It is ideal for the fabrication of prototypes. With a maximum tree size of 500 x 500 mm it is especially suited for R&D and investment casting service companies.

FR

FR