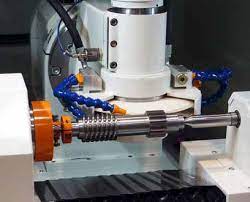

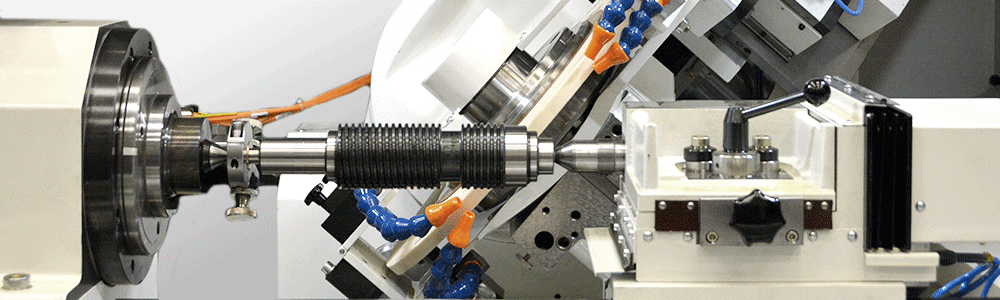

Rotational form and thread grinding machine

The specific MIKROMAT software enables the user to combine their special grinding skills with the company‘s know-how. The 6 axes managed by the CNC grinder allow designing highly complex shape elements.

Optimal dressing of grinding tools is provided for all grinding jobs: NC dresser, dressing unit with diamond wheel, steel pressure roller and conventional dressers. There is no need to plan preliminary machining of contours of any kind using other machining processes. The machine allows automatic and complete grinding of work pieces.

A modern, thermally-controlled, high-capacity coolant system creates the preconditions required for highly productive and intensive grinding with constant accuracy.

These grinders are very modular and particularly suitable for external grinding operations for highly-precise small and medium series.

The MIKROMAT machines, with additional equipment, can perform operations such as internal grinding, relief grinding, axially-parallel grinding, pitch- and diameter progressive grinding…

The integrated automated systems for loading and unloading work pieces allow efficient and highly-precise machining of medium and large series.

Thread grinding requires experience and mechanical knowledge. However, programming skills are not necessary, since drawing specification are entered directly.

FR

FR