Meltio Space Software

This comprehensive product offers custom-developed Meltio print profiles for the extensive Meltio materials portfolio. Not only does the Meltio Space robot slicer provide exceptional functionality, but it also ensures low

capital and running costs, which are further reflected in the software licensing model.

Meltio Space is an innovative addition to the Meltio product lineup, offering a new perspective on 3D printing by breaking free from the limitations of traditional 3-axis systems. This revolutionary software takes a step further and expands the possibilities by incorporating advanced robotic manipulation capabilities.

Empowering Meltio users

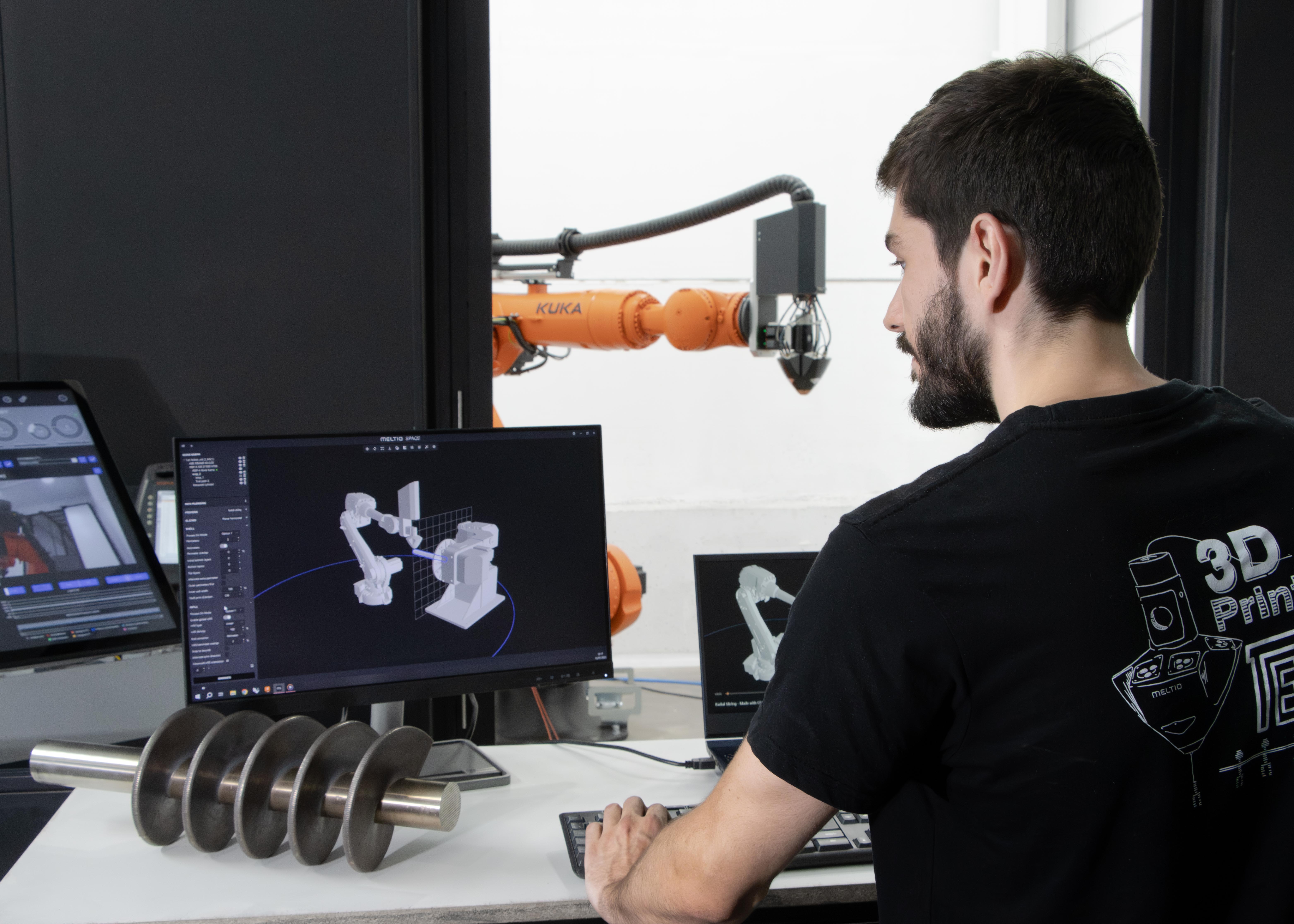

Meltio Space, specifically developed for the accelerated adoption of Meltio technology, revolutionizes the field of robotic additive manufacturing.

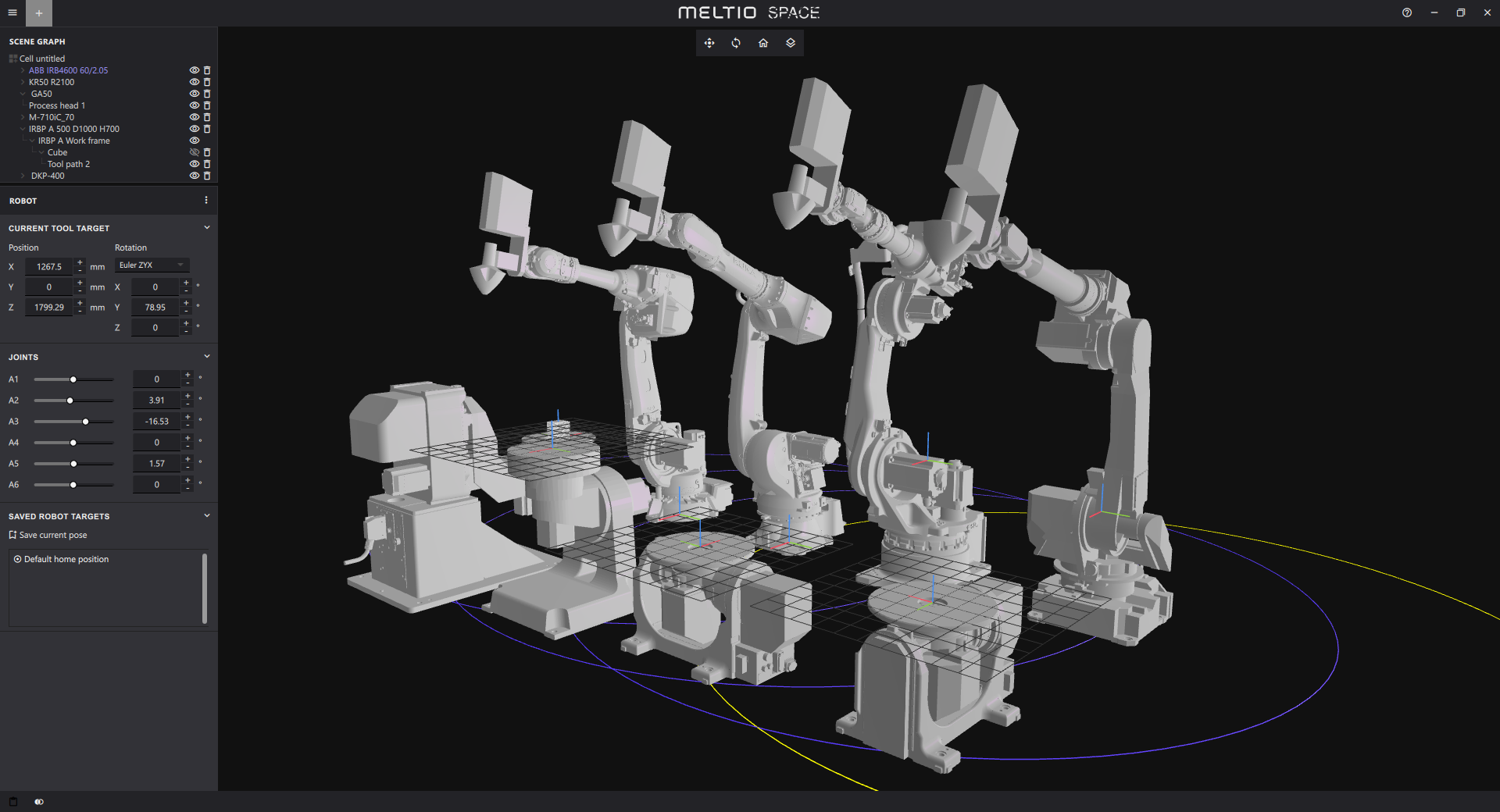

With its intuitive design, users can quickly adapt to and leverage the benefits of robotic additive manufacturing without requiring expertise in robotics or programming. By offering a user-friendly interface and comprehensive features, this advanced robot slicer simplifies the integration of the most popular robotic brands with a built-in robot library and post-processors for ABB, Kuka, FANUC, and Yaskawa. Unlike other software solutions, the Meltio Space robot slicer includes these features at no extra cost.

Moreover, our software removes complexity in the 3D printing workflow, making it accessible to users of all levels. Whether it’s understanding the interpolation of workpiece positioners or applying slicing strategies, Meltio Space streamlines the entire process, enabling users to embrace the power of additive manufacturing with ease offering a unified platform that enhances workflow efficiency and productivity.

Unleashing the full potential of Meltio Engine with Meltio Space

This cutting-edge software solution offers a comprehensive set of advanced features designed to maximize the Meltio Engine functionalities. Meltio Space provides specific print profiles optimized for different applications and materials, ensuring exceptional results and saving you valuable time on manual adjustments. Dual wire features are also facilitated

in the software. With Meltio Space, you have the power to unlock the full potential of your metal 3D printing projects, pushing the boundaries of what is possible in additive manufacturing.

Unlocking Complex Geometries with Ease with a Wide Range of Toolpath

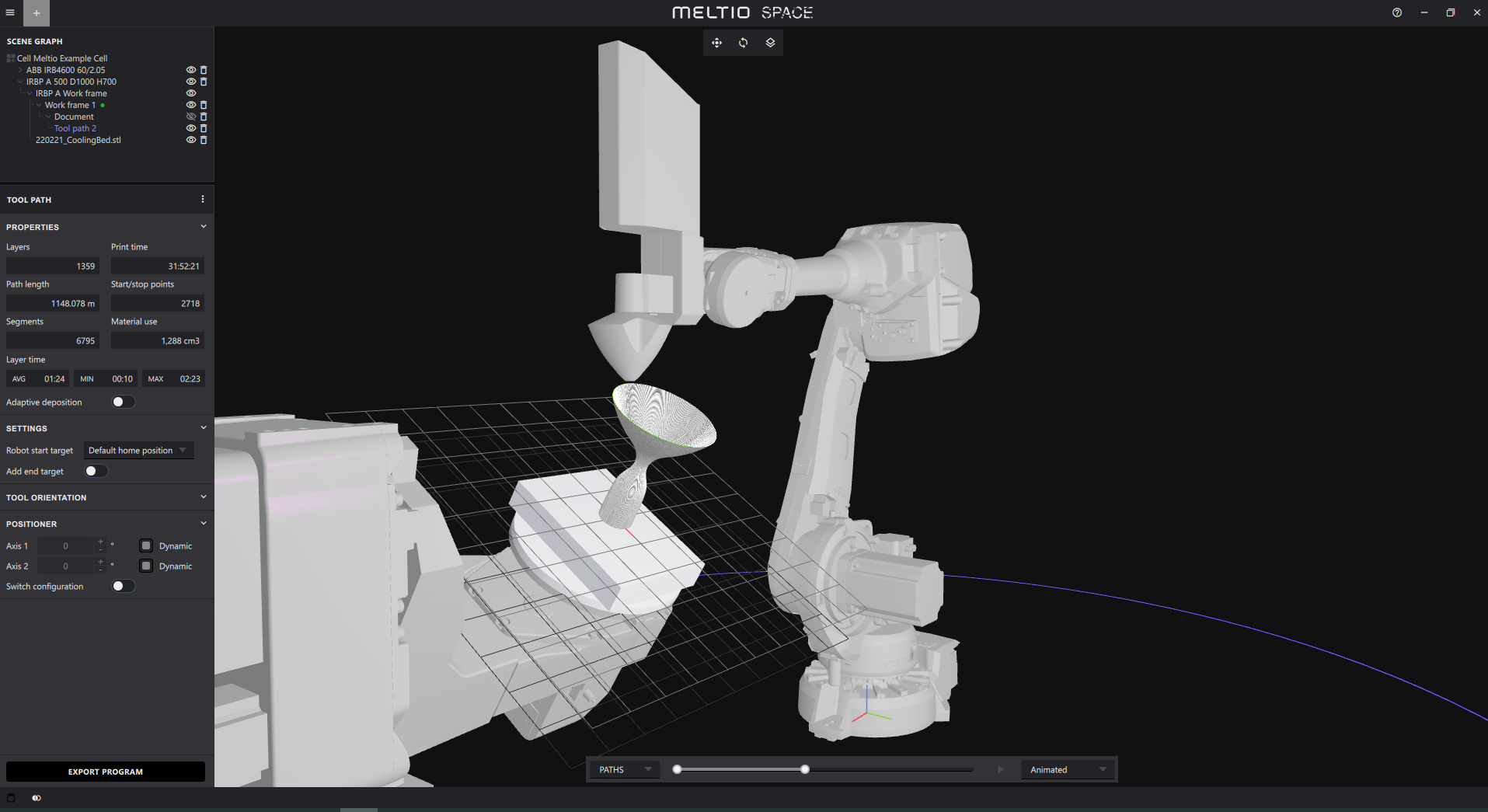

Strategies at Your Fingertips: With Meltio Space, bid farewell to the limitations imposed by three axes and the need for extensive support structures. Our software offers an extensive selection of toolpath strategies, catering to diverse additive manufacturing applications. Whether it’s planar, non-planar, or variable extrusion toolpaths, these strategies can be easily defined within the software, you can choose the most suitable toolpath strategy that aligns with your specific needs, ensuring optimal

print quality and efficiency. Adjusting the angle of attack or choosing from different interpolations of workpiece positioners is as simple as a few clicks, enabling precise and intricate movements that bring your designs to life in ways that were previously unattainable like maintaining the tool vertically avoiding even the affectance of gravity for massive overhangs without hassle.

Reduce programming time safely, time savings, more productivity

Meltio’s state-of-the-art technology significantly reduces programming time, resulting in time savings and increased productivity. To guarantee excellent results, the Meltio Space robot slicer employs a virtual model of the real robot movement. This advanced feature allows users to simulate the kinematics of the robot, ensuring accurate and precise printing. Additionally, the slicer performs collision checks with the part being printed, minimizing the risk of errors or damage during the additive manufacturing process.

FR

FR