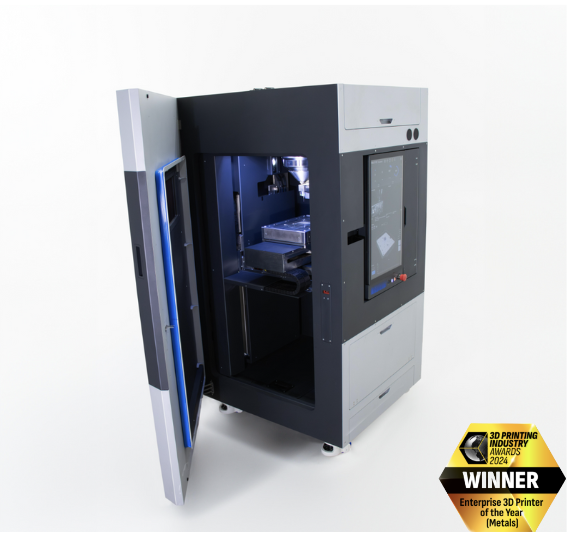

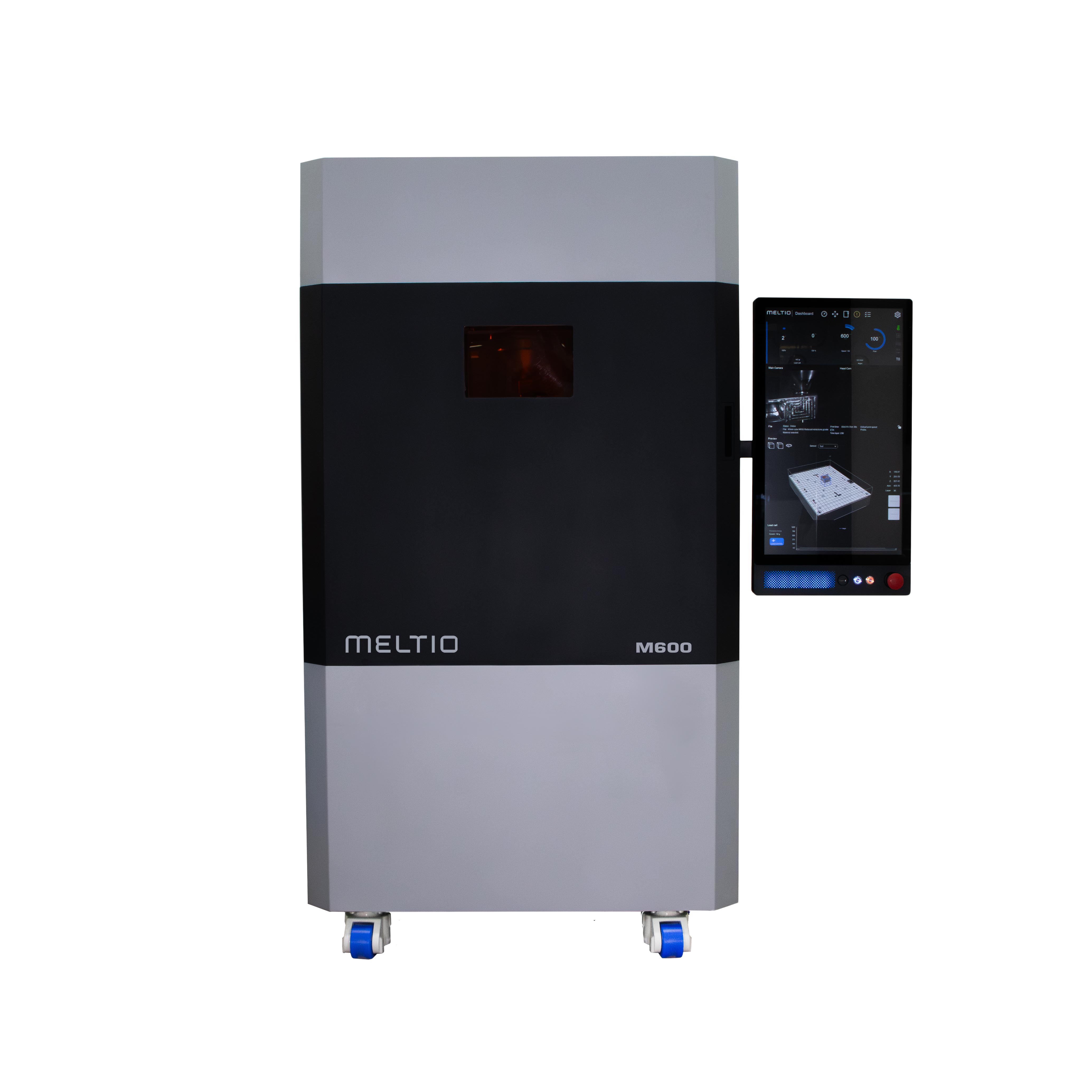

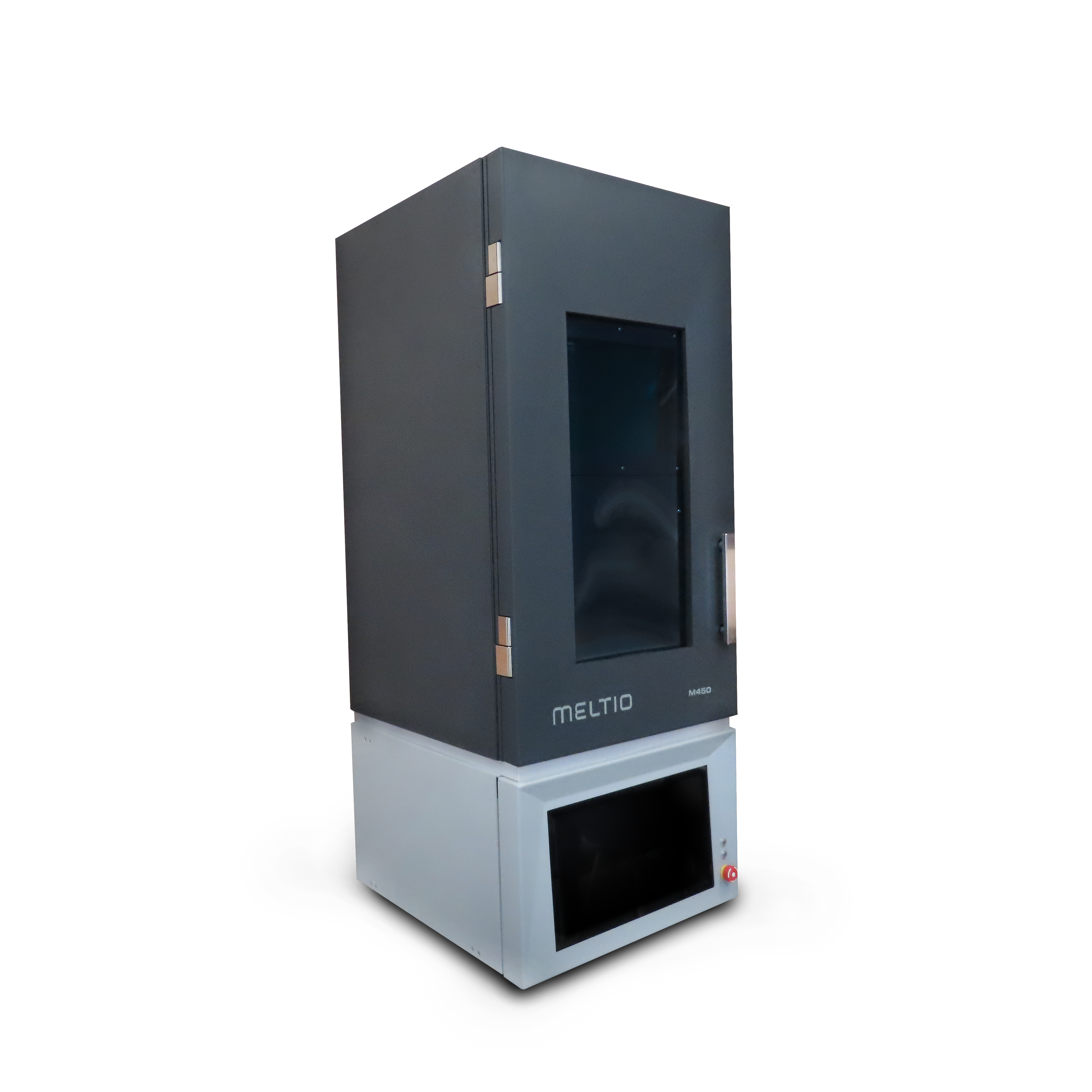

Why Choose Meltio M600?

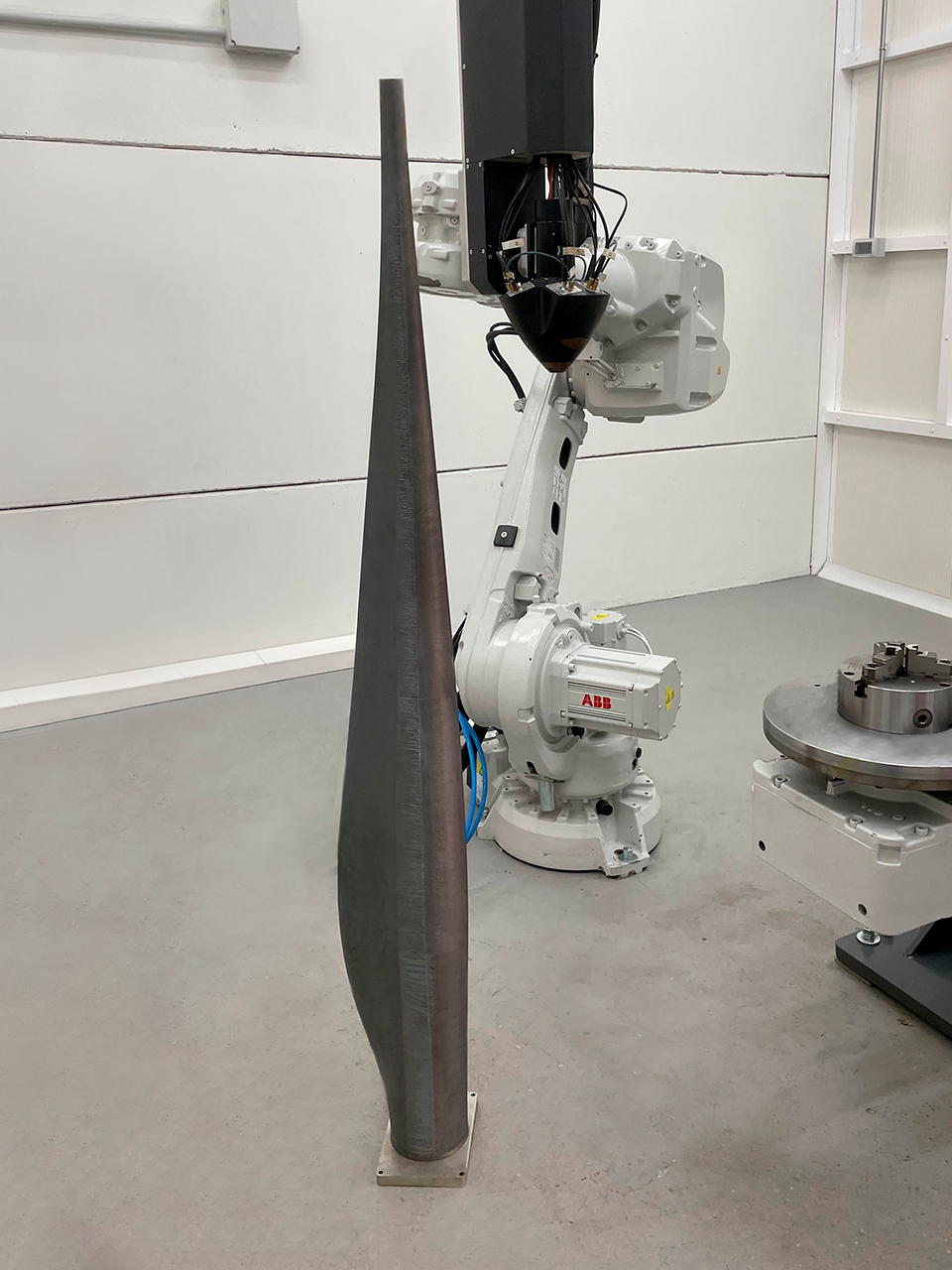

1. Production Ready

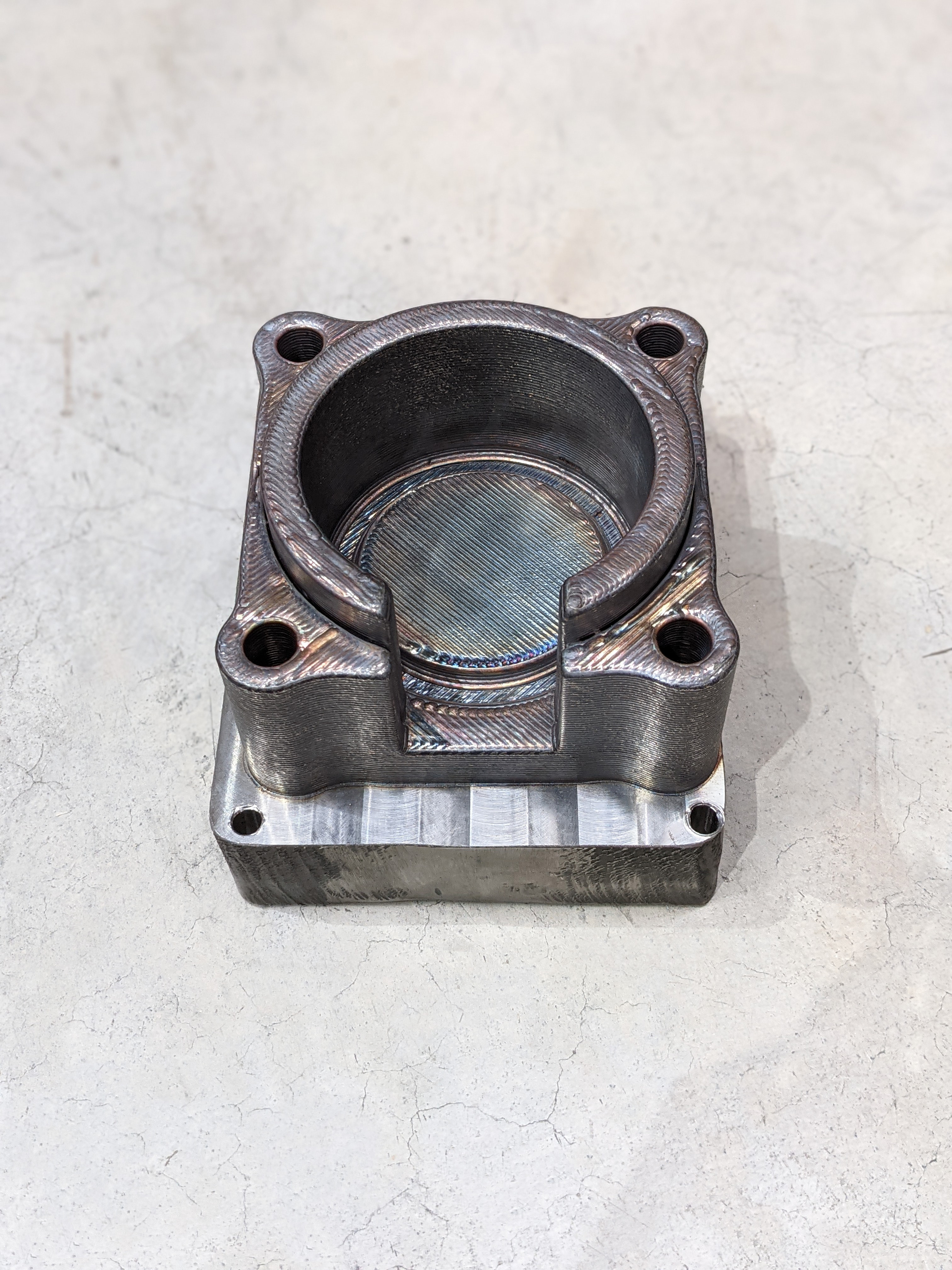

Bigger parts, higher deposition rate, larger material range, inert print chamber, less maintenance, and built-in orkholding solutions make for a production ready system.

2. Ease of Use

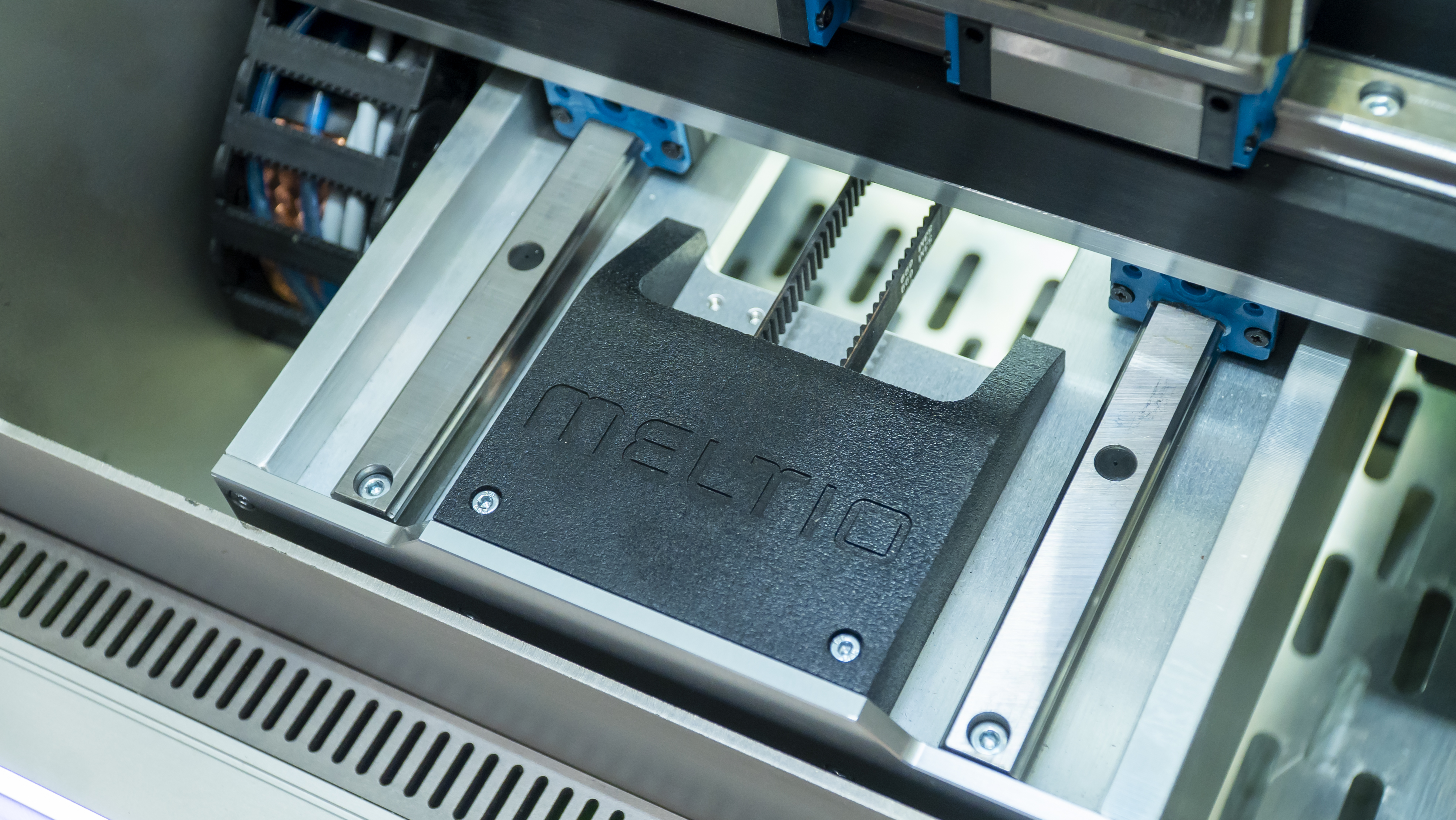

Advanced sensor solutions, simplified UI, dedicated slicer, zero point clamping system, and probe system. All designed to minimize operator interaction.

3. Reduced Maintenance

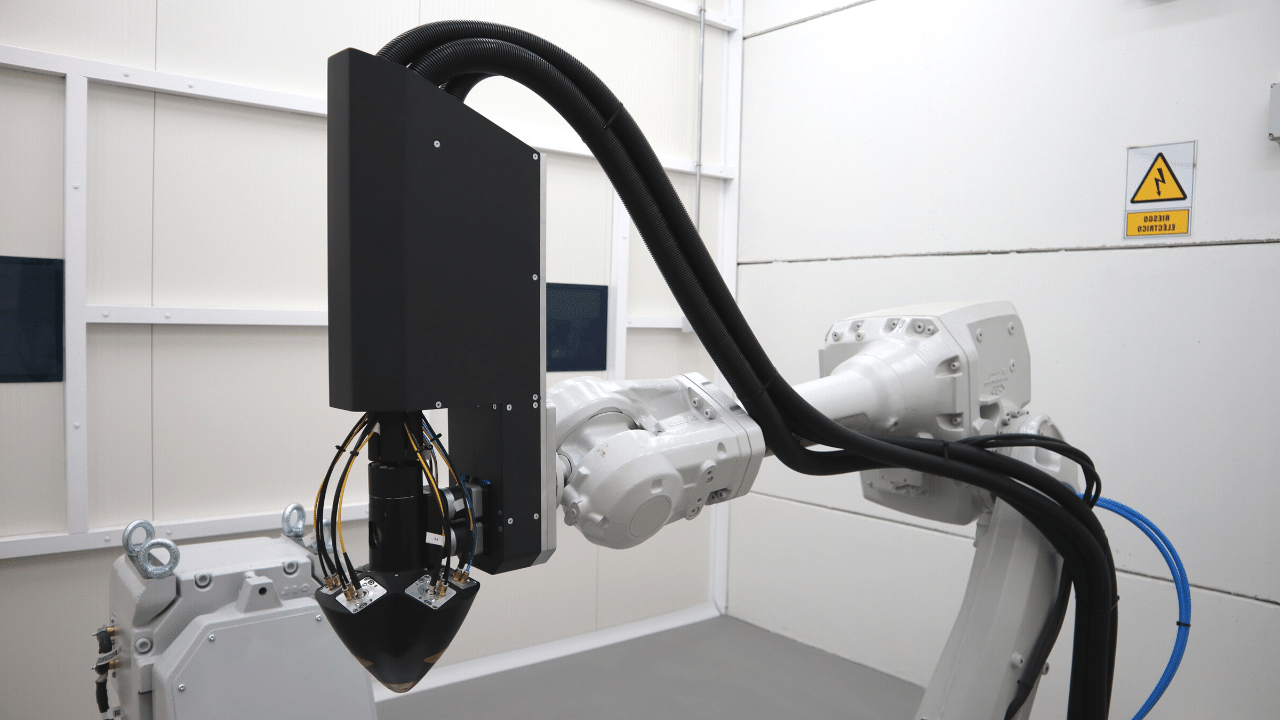

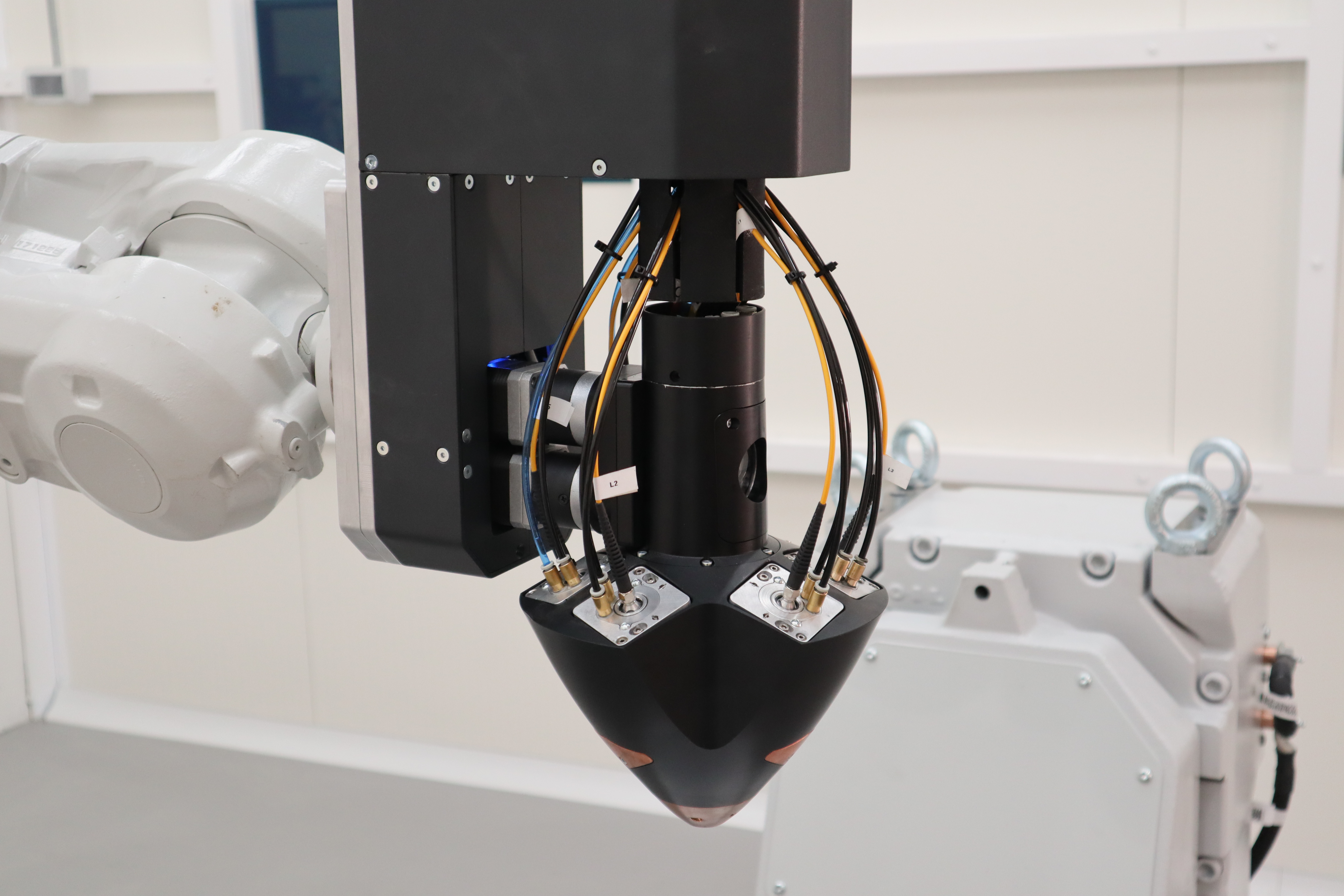

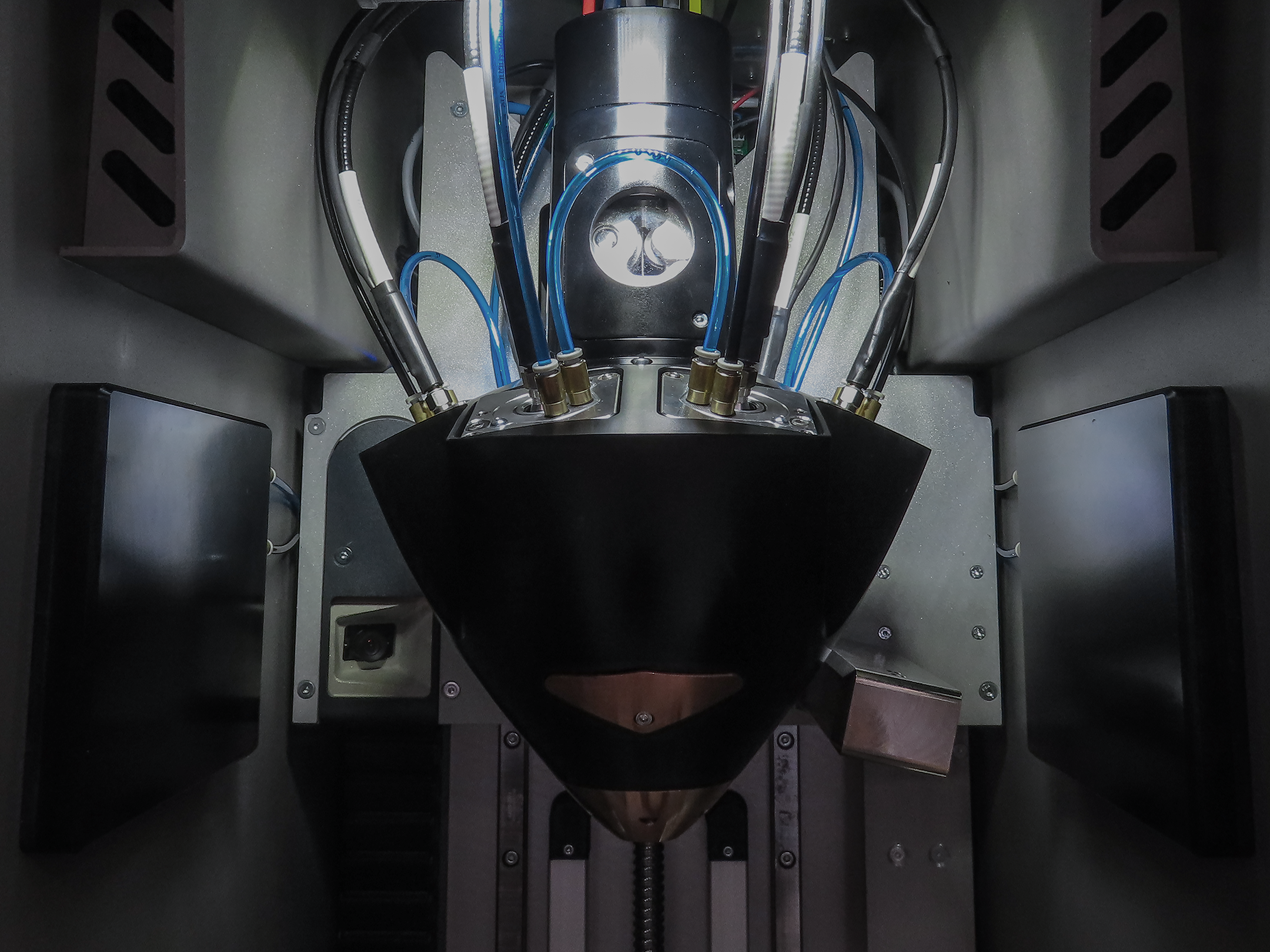

The newly developed deposition head removes the need for laser alignment, while the motion system has been

improved and over-sized to ensure maximum life-time.

4. Stability, Repeatability, Reliability

Improved wire feeding system, fiber free deposition head, improved process control systems, and many more making for an extremely reliable machine.

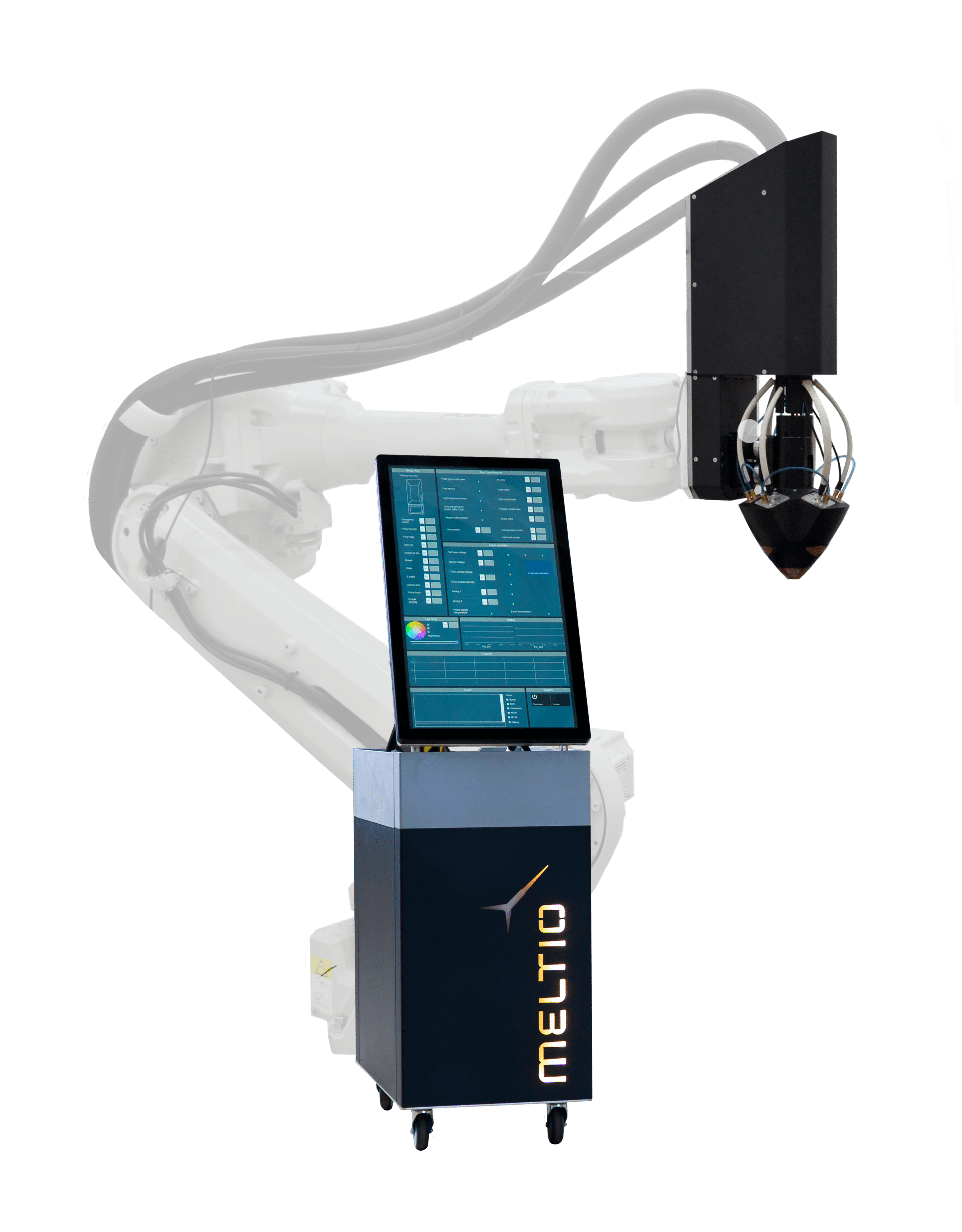

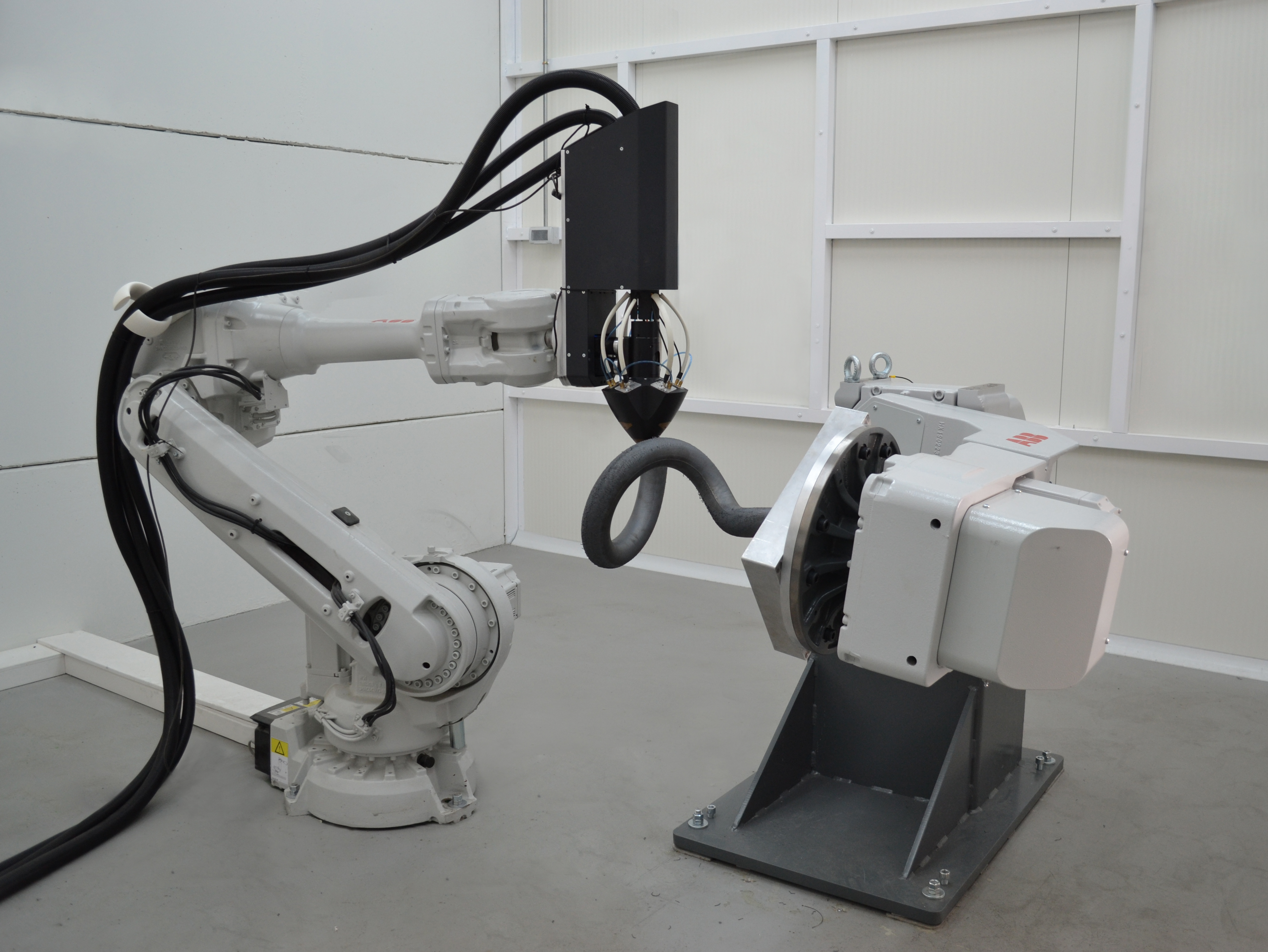

5. Automated Integration

Integrating the system into existing manufacturing workflows becomes easy thanks to the compact footprint and flexible workholding architecture.

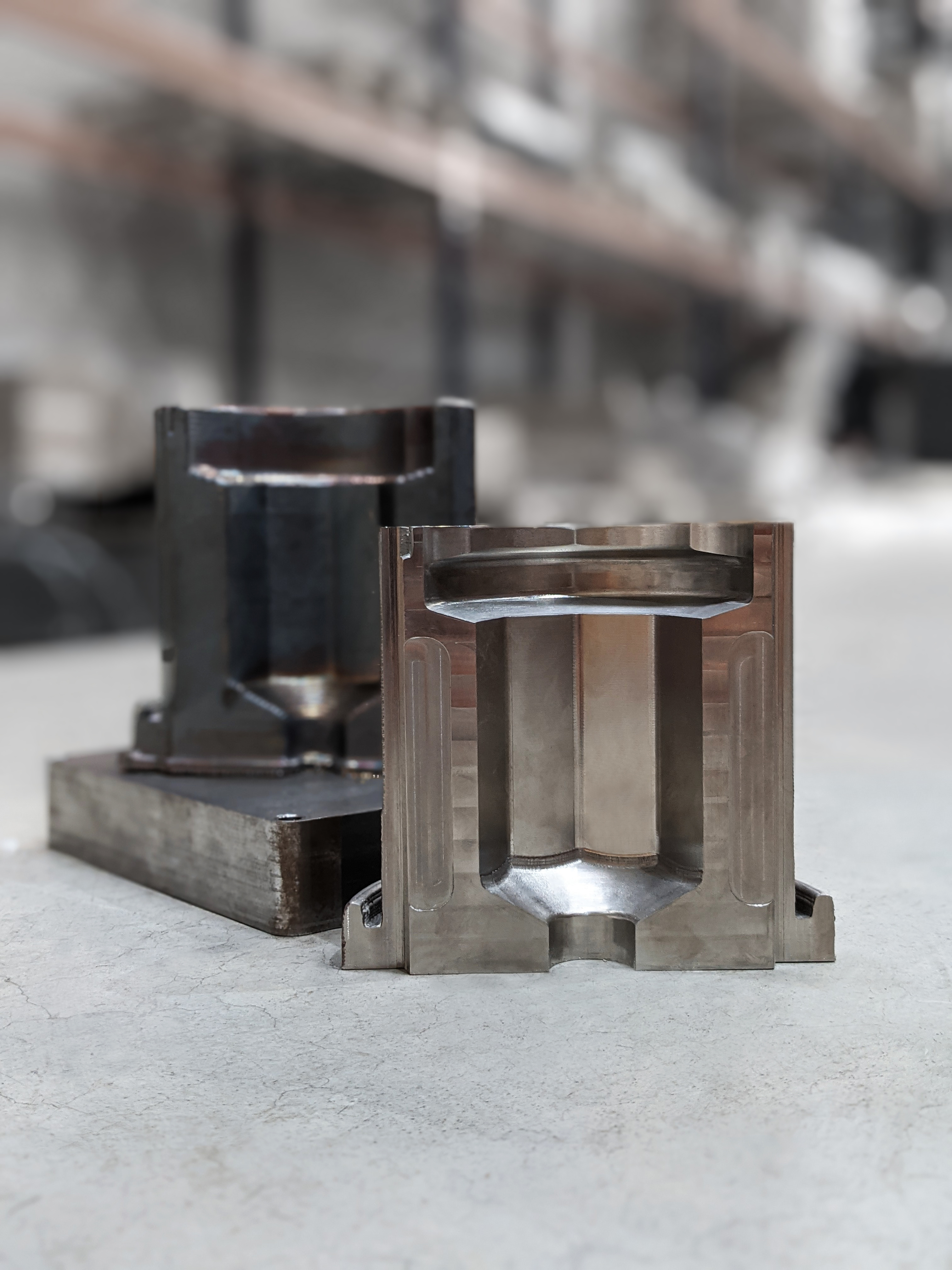

6. Increased Working Volume

Fully inert printing volume of 300 x 400 x 600 mm expands manufacturing possibilities to larger components while improving the quality for highly reactive materials like titanium.

7. Cost Saving

Thanks to the high efficiency Blue Laser diodes and the increased absorption, the energy consumption per component is reduced significantly, resulting in a greener and more cost efficient process.

Find out all the main questions about the Meltio M600 by clicking HERE

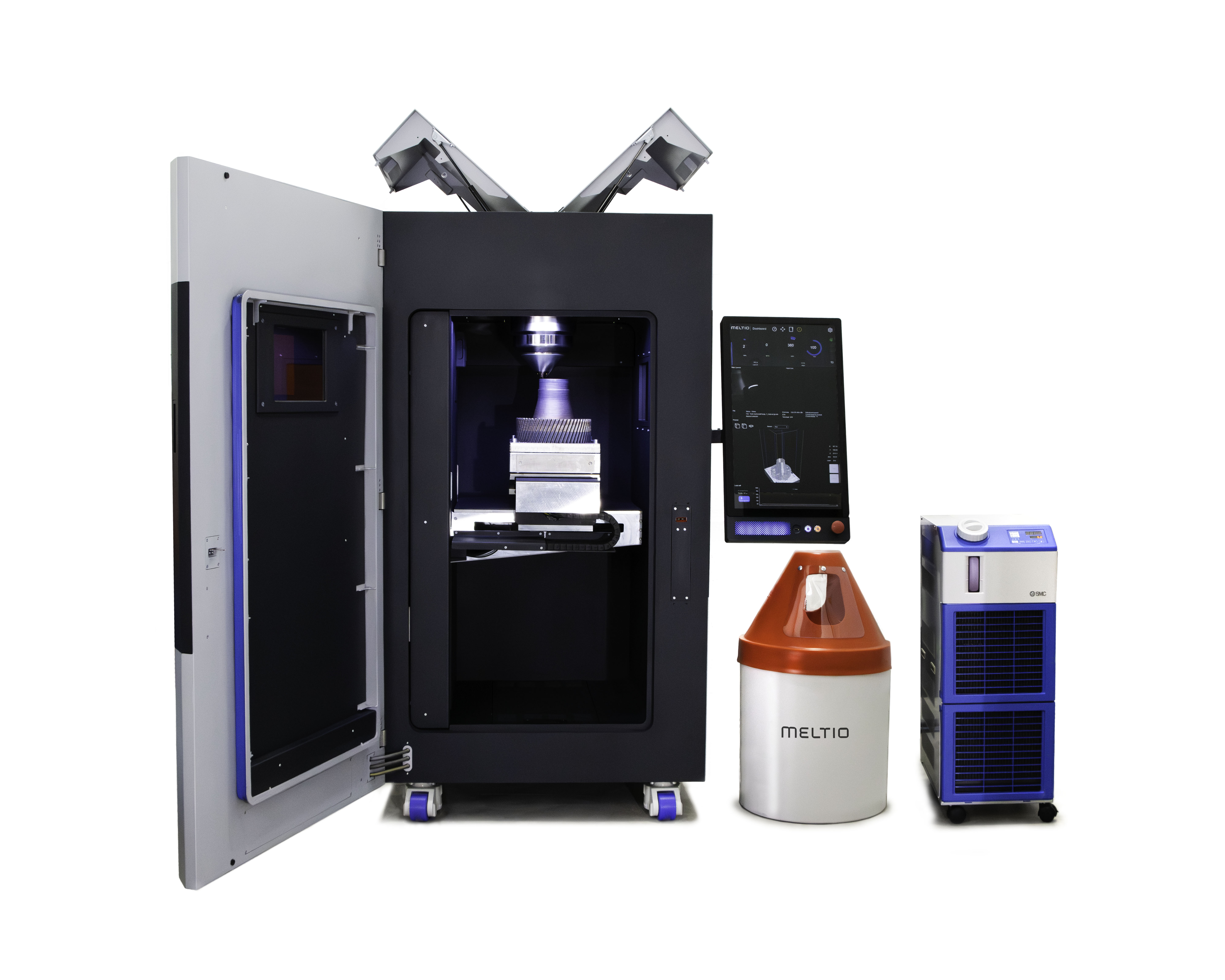

OPTIONS :

- DUAL and QUADRUPLE WIRE : Options for printing with up to four different materials in the same print sequentially with the reliability of a single wire process.

- WIRE DRUM READY : The wire drum connector allows for a reliable and industrial feeding system for material spools of +100kg.

- HOT WIRE : Programmable power supply that preheats the material to increase the deposition rate.

- ZERO CLAMPING POINT

HORIZON SOFTWARE

Meltio Horizon is a proprietary toolpath generator software for 3-axis metal 3D printing, tailored specifically to our laser-wire deposition process with the Meltio M450 and Meltio M600 metal 3D printers.

Simpler profile selection and premade profiles that cover a large range of geometries and qualities.

FR

FR