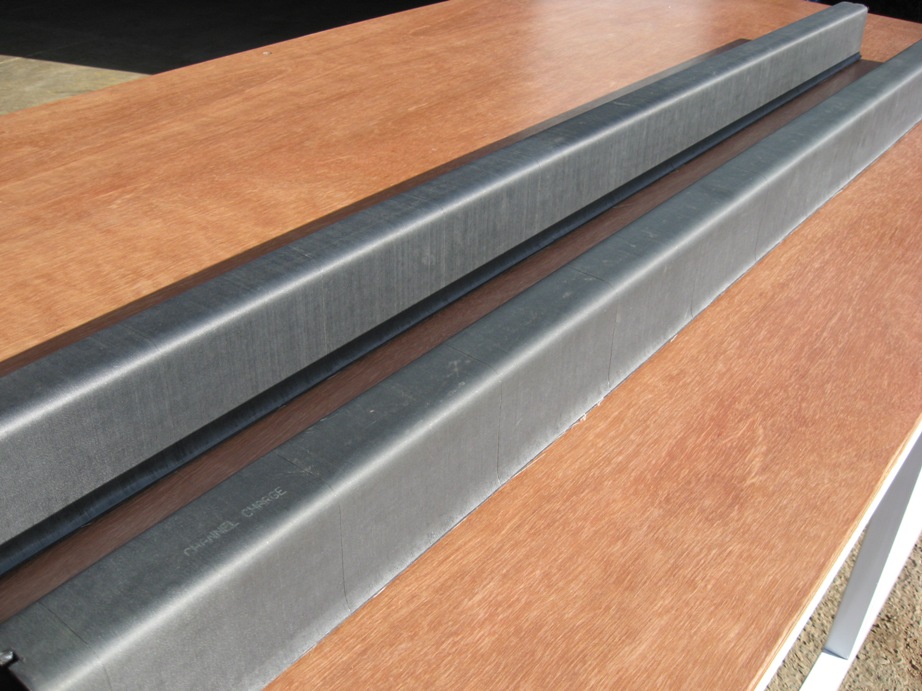

The Hot Drape Former (HDF) machines are ideal for pre-forming carbon fibre components for the aerospace, automotive and marine industries. That’s because they produce high quality composite parts faster than the traditional solution of hand lay-up.

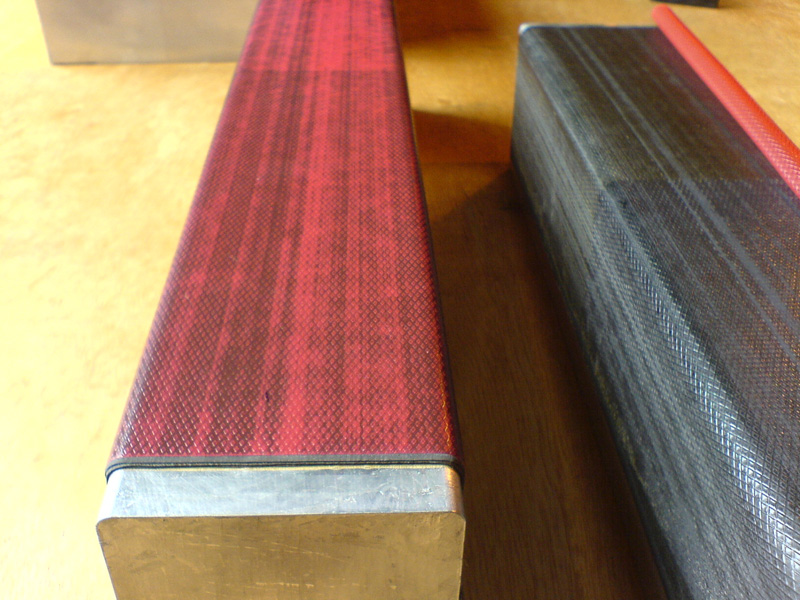

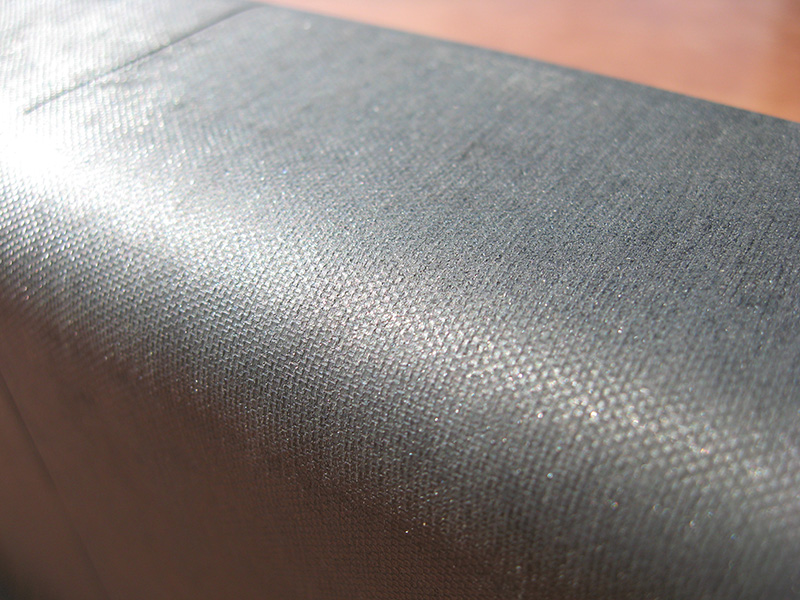

Composite materials such as carbon fibre are often used in the aerospace industry as they have a high stiffness and strength-to-weight ratio. Our hot drape formers feature an infrared radiation heating system that softens the carbon fibre quickly and evenly. This allows the layers to slip against each other and produce accurate parts free from any stress wrinkling.

Multiple ply lay-ups can be formed into shape quickly and easily. As well as hot drape forming, these machines can also be used for:

- Forming Pre-preg carbon fibre

- Out Of Autoclave (OOA) composite curing

- Honeycomb bonding

- Vacuum debulking

The machines meet the exacting standards demanded by aircraft manufacturers and have been used from the Harrier and Gripen, though to our current machines working on the Boeing 787 and 777X programmes.

All the hot drape formers are built to last and with ease of maintenance in mind. Each model comes with a two-year warranty as standard, is clean room compliant, CE certificated and offers reliable performance and long life for professional hot drape forming.

FR

FR