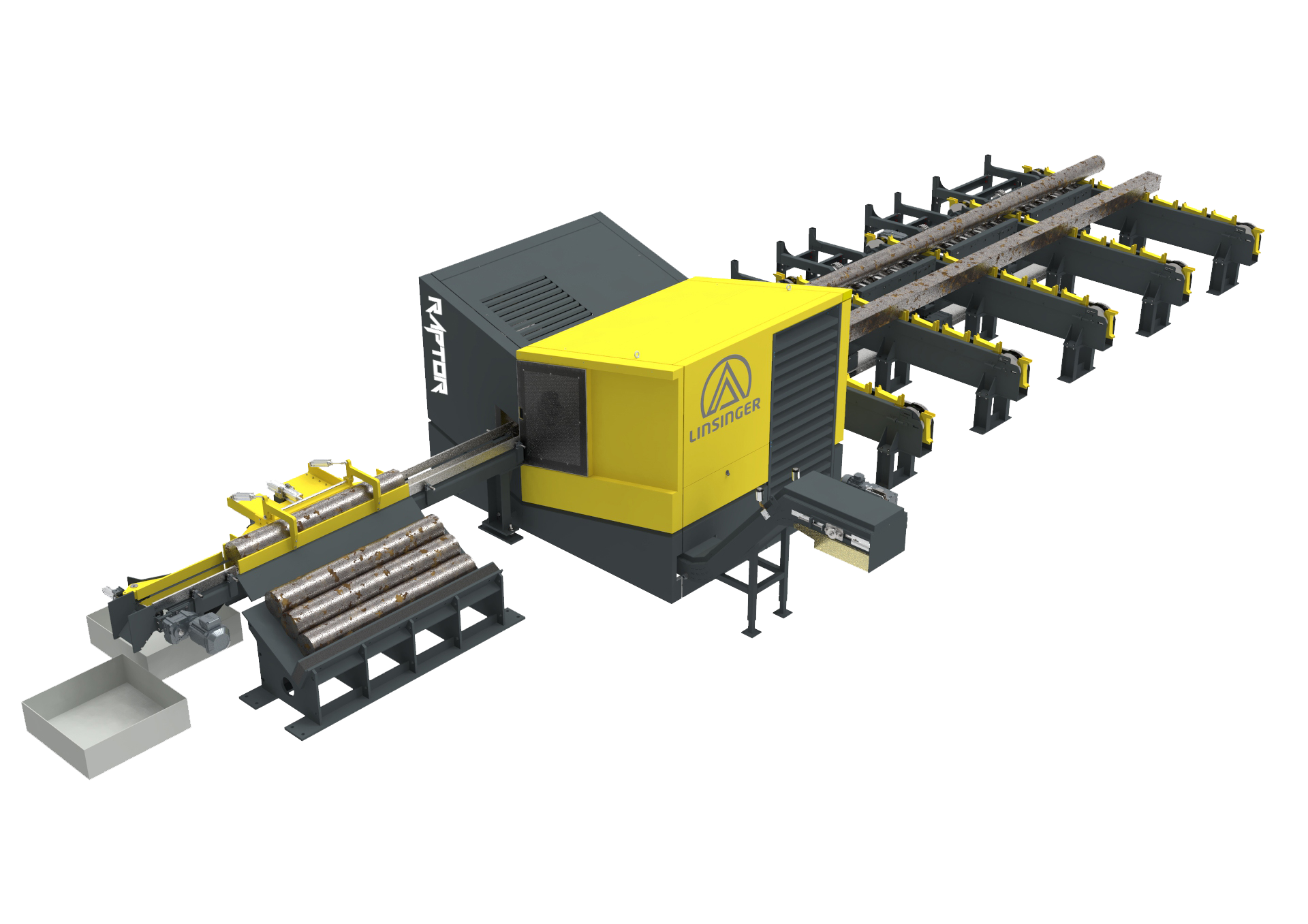

LINSINGER SAWING TECHNOLOGY

Machines of the RAPTOR® family completely refrain from using hydraulics. As a result, bulky components such as pumps, pipelines, hoses, or accumulators are completely eliminated. The removal of hydraulics allows for a quieter machine overall, with a significant reduction in noise pollution. The reduced risk of pollution caused by leaking oil, fires or accidents at work underlines the “green and safe” philosophy of this machine once again.

PREMIUM FEATURES

- LINSINGER heavy duty gearbox

- Contact-free saw blade return

- Central lubrication of all spindles and linear guidings

- Cooling and lubricating technology for saw blades

- Linear guided saw feed with ball-screw spindle and servo motor

- Frequency controlled main drive with high power reserves

- Fully-integrated switch cabinet resulting in small footprint and quick installation

ADVANTAGES

- Monitoring Software : monitoring software to collect machine and production data

- Process Control : get better insights on your production

- Preventive Maintenance : self-diagnostic software helps you to eliminate unplanned stoppages

- Free of Hydraulic : latest state of technology – due to our innovative machine concept, the use of hydraulic fluid becomes obsolete

- Integrated Control Panel : RAPTOR Easy Touch. Easy input of material, cutting & tool data

BEAT THE ELEMENTS

The RAPTOR® machine has been designed to be applicable for all requirements. A wide range of materials can be cut the most economic way due to heavy rigid machine design, highest main drive power, first class components and the overall experience of the successful LINSINGER Sawing Technology.

STEEL

- Heat Treated Steel

- Mild Steel

- Alloyed Steel

- Carbon Steel

- Machining Steel

- Nitriding Steel

HIGH ALLOYED STEEL

- Duplex

- Super-Duplex

- NiCr based Alloys

- Hot Work Steel

- High alloyed & Stainless Steel

- Tool Steel

- Cold Work Steel

- Super Alloys

NON-FERROUS

- Aluminium

- Titanium

- Brass

- Bronze

- Copper

FR

FR