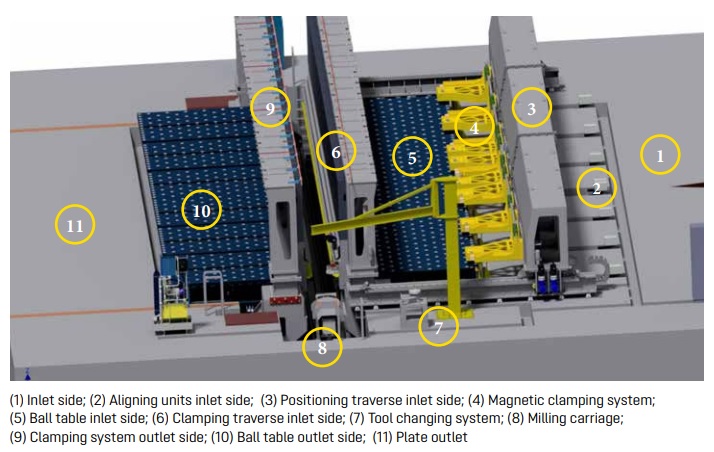

Linsinger Panel Line for shipbuilding

Linsinger´s Panel Line – two-side plate edge milling machine – is designed for the simultaneous milling of two plate edges which are to be joined by a welding. By means of the machine concept it is possible to join the plate edges to be welded so that there is a weld („0“ – GAP) which is necessary for the modern laser-hybrid welding process in this field of application. For this purpose, the plate clamping and parallelism after the simultaneous processing of the two plate edges is kept constant until after the welding of the plates thus preventing a spring back or displacement of the plates.

Highlights

- Different plate thicknesses can be used without affecting the welding quality

- High productivity due to simultaneous milling on both longitudinal sides

- Weld seam preparation with maximum accurancy ( „0“ – GAP )

- No turning and rotating of the plate required

- Linsinger own tool management with automatic tool changer

- Safty factor due to your improvement in your working enviroment

- Ensure your international competitiveness

- With 300 working days per year, it is possible to produce about 600 panels of size 24 m x 36 m in two shifts in one year.

FEATURES

- total weight: 760 t

- milling power: 75 kW

- milling speed: 10 m/min

- max.sheet thikness: 25.4 mm

- max. panel size: 30 m x 36 m

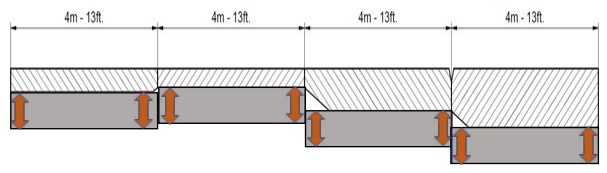

The machine table on the infeed side is equipped with a height adjustment. By means of this height adjustment plates with different thicknesses can be machined with chamfering from below (no thickness variation on the plate top surface is allowed).

ADJUSTABLE CLAMPING TABLE

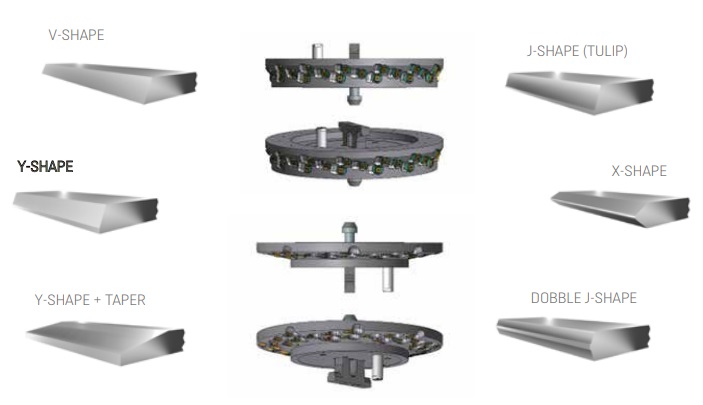

MILLING UNIT AND SHAPES

The milling unit moves with a feed rate of 200 – 10,000 m/min depending on overwidth and plate thickness. In addition to this, the advance feed can be moved with a rapid motion of 30 m/min for the return movement into home position.

For weld seam preparation and for the chamfering from below (1:4). Seam contour adapted to the welding process.

FR

FR