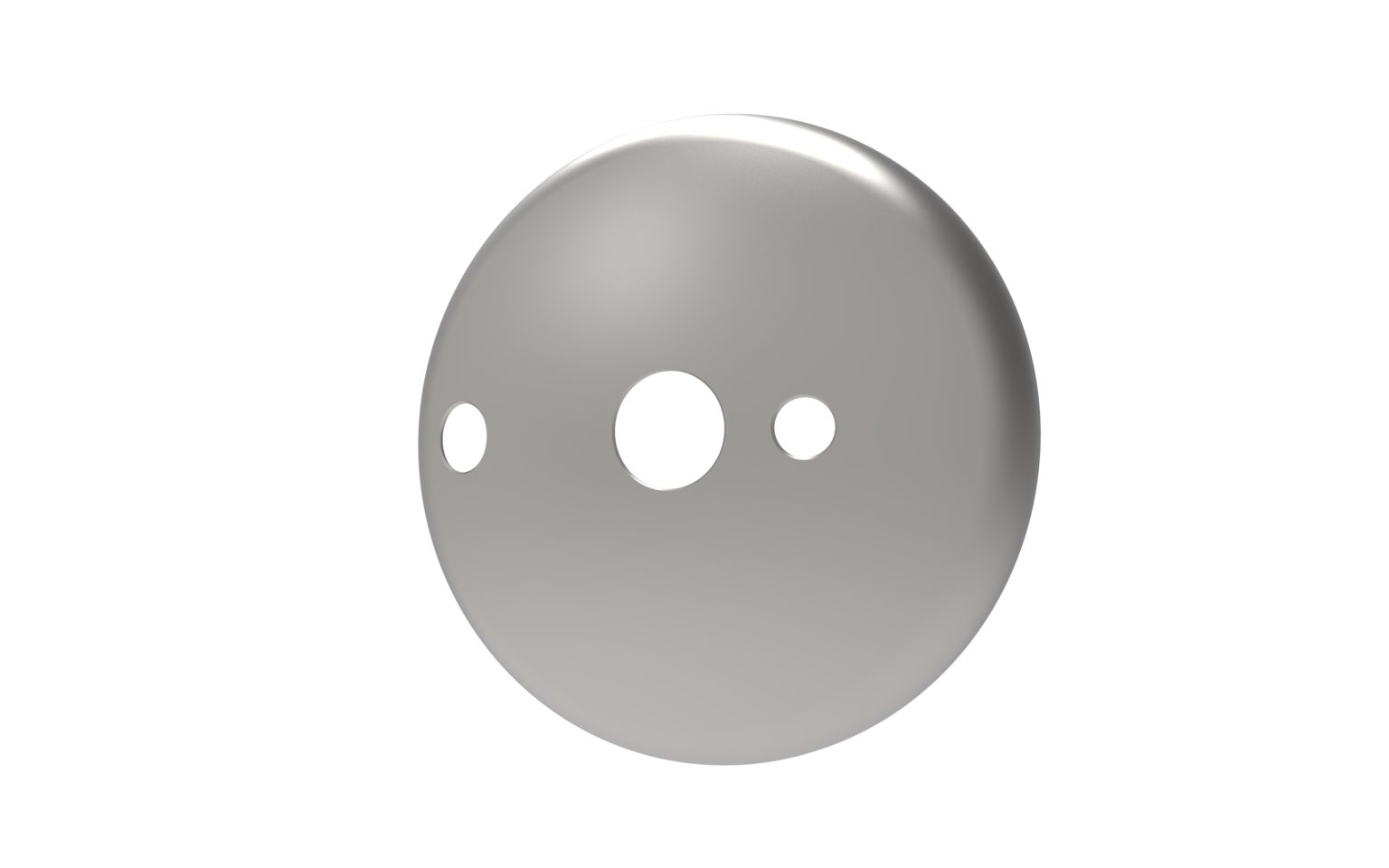

A wide range of machine models and sizes is available, guaranteeing productive and full-automatic beveling of dished ends from only 25mm (1”) up to 7.000mm (275”).

Linsinger longtime tool expertise ensures low tool cost and economic machining even of stainless steel and high alloyed materials.

Check out the optional features of all machines, such as automatic measuring, stacking of finished pieces, drilling of holes or even milling of ball tank segments and press stamps.

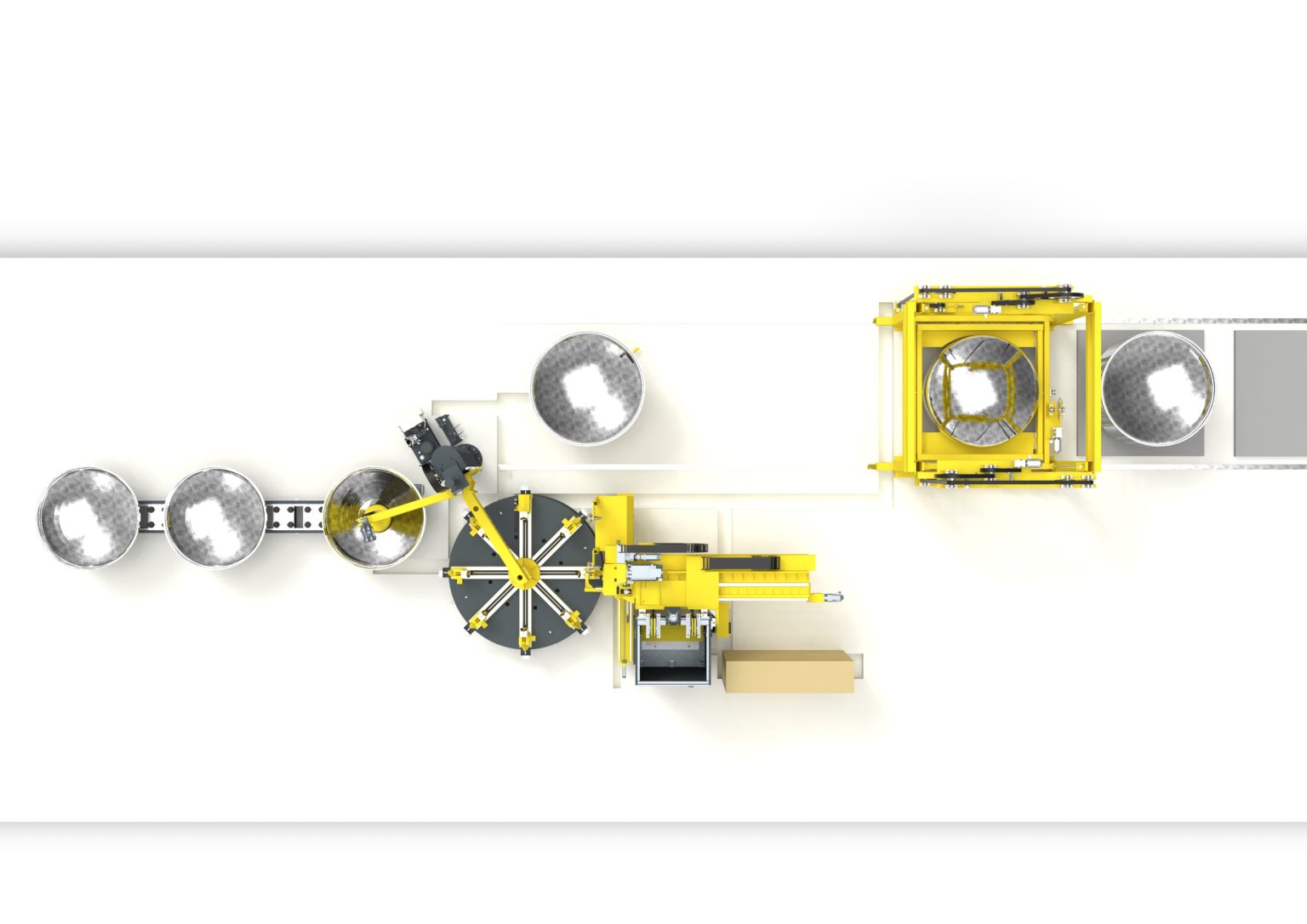

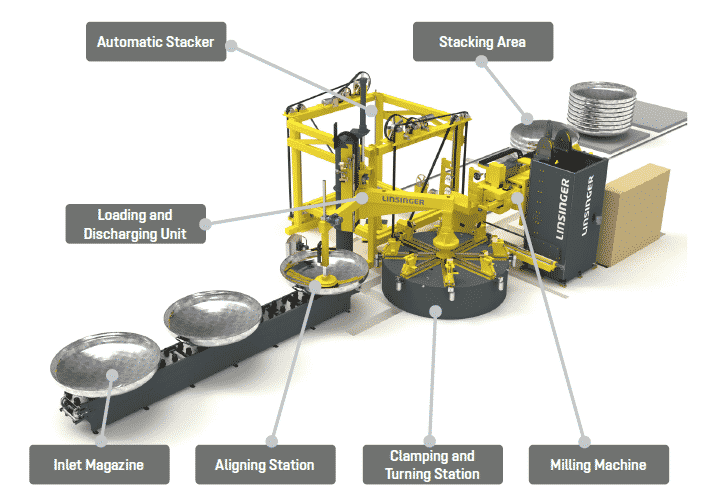

Orbit : automatic boiler end bevelling machines

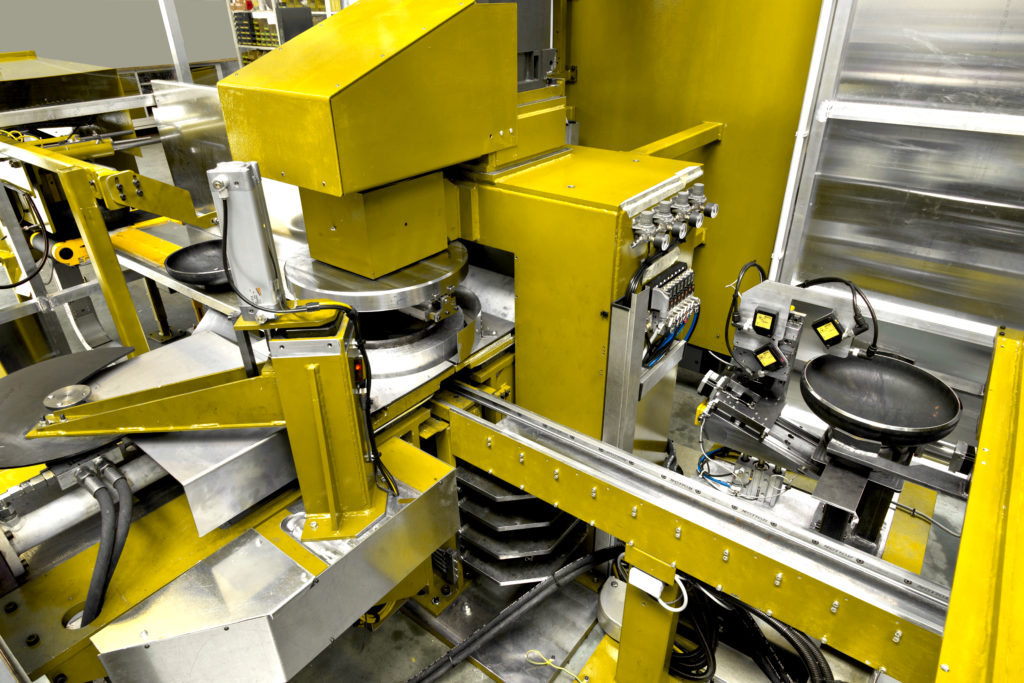

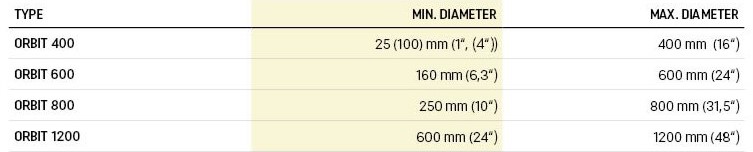

DIAMETER 25 – 1200 MM

features

- Fully automatic machining cycle

- Designed for highest possible output

- Automatic and precise alignment of boiler ends

- Quick tool and diameter change

- Precise and fast welded seam preparation

- Various kinds of profiles available (V/X/Y/J…)

- Optional drilling function available

- Optional measuring station for quality assurance and documentation

AVAILABLE MODELS

AVAILABLE OPTIONS

- Automatic measuring of finished boiler ends

- Processing of stainless steel and other high alloyed materials

- Automatic marking of finished boiler ends

- Automatic stacking and turning of finished parts

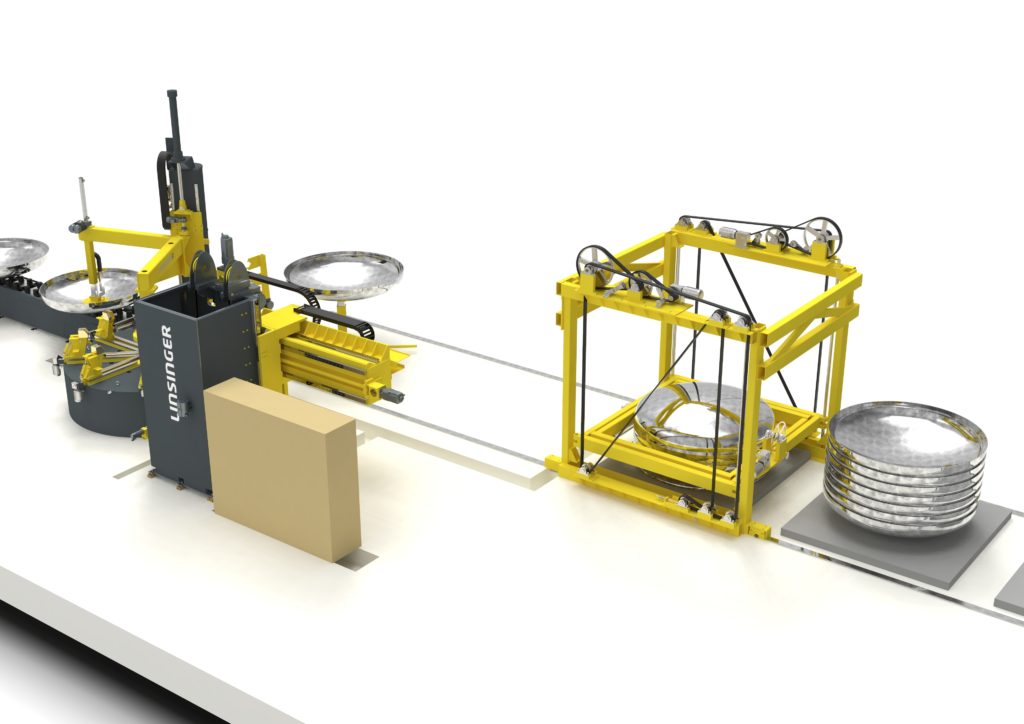

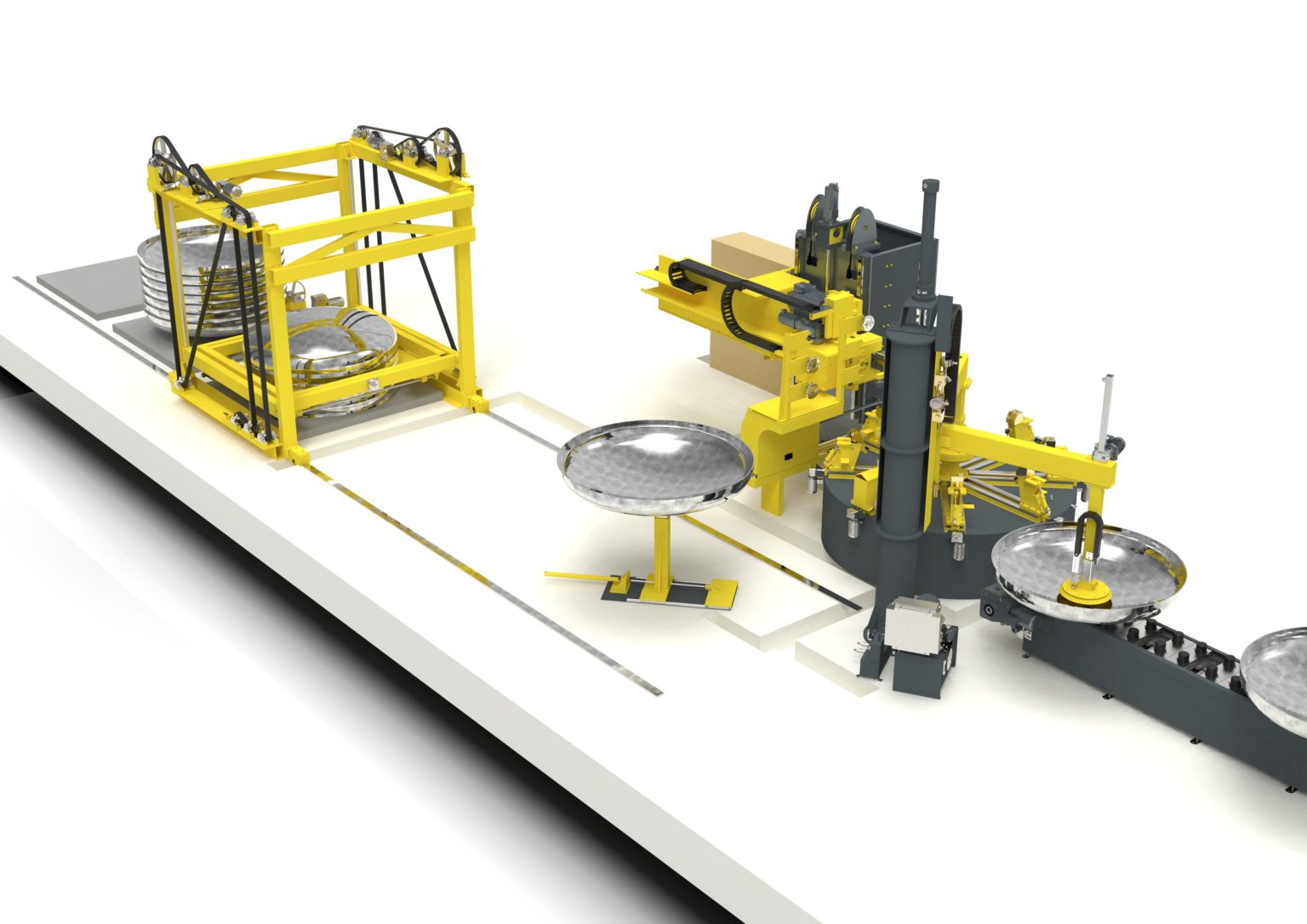

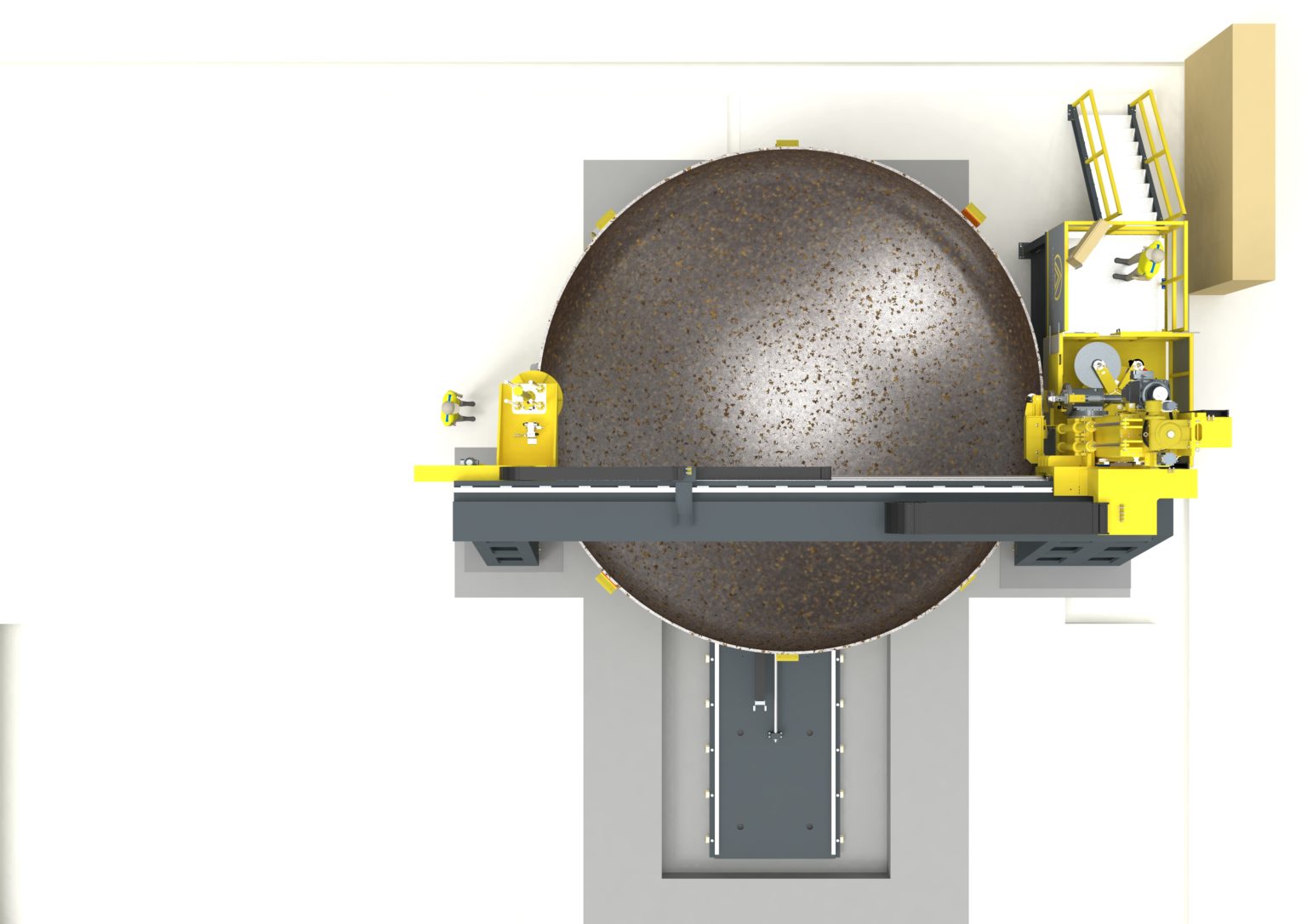

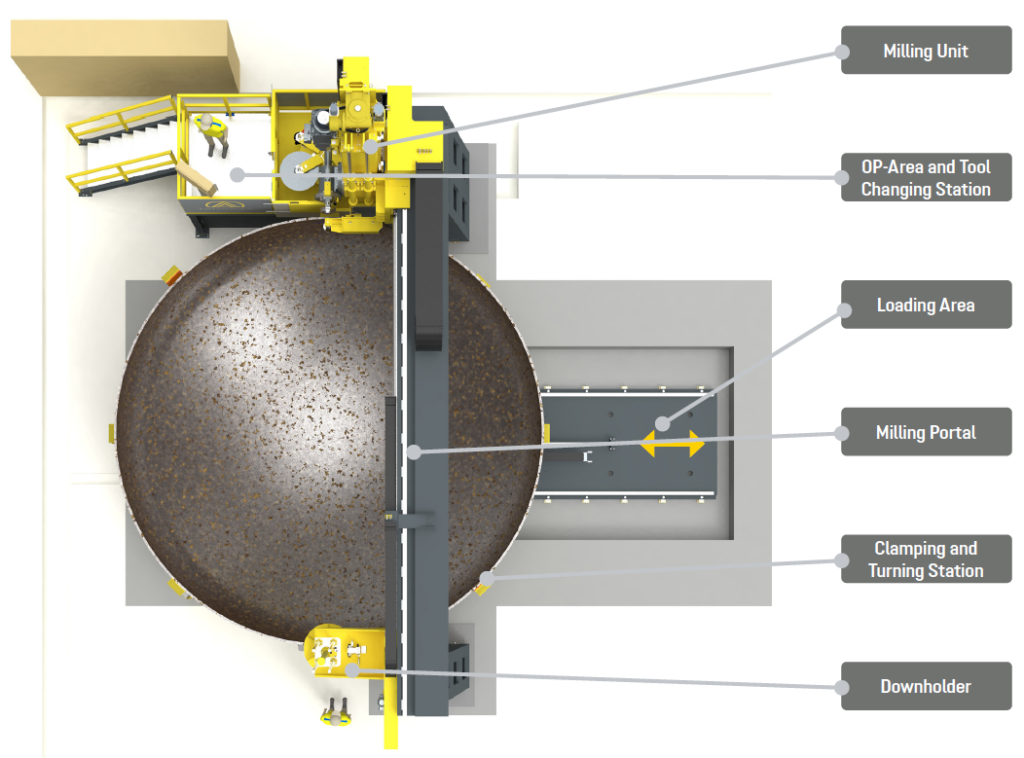

DIAMETER 600 – 2400 MM

FEATURES

- Fully automatic machining cycle

- High bevelling performance

- Automatic machine setup for every diameter

- Automatic and precise alignment of boiler ends

- Precise and fast welded seam preparation

- Various kinds of profiles available (V/X/Y/J…)

- Automatic tool changer function available

- Optional measuring station for quality assurance and documentation

APPLICABLE FOR:

AVAILABLE OPTIONS

- Processing of stainless steel and other high alloyed materials

- Automatic marking of finished boiler ends

- Automatic stacking and turning of finished parts

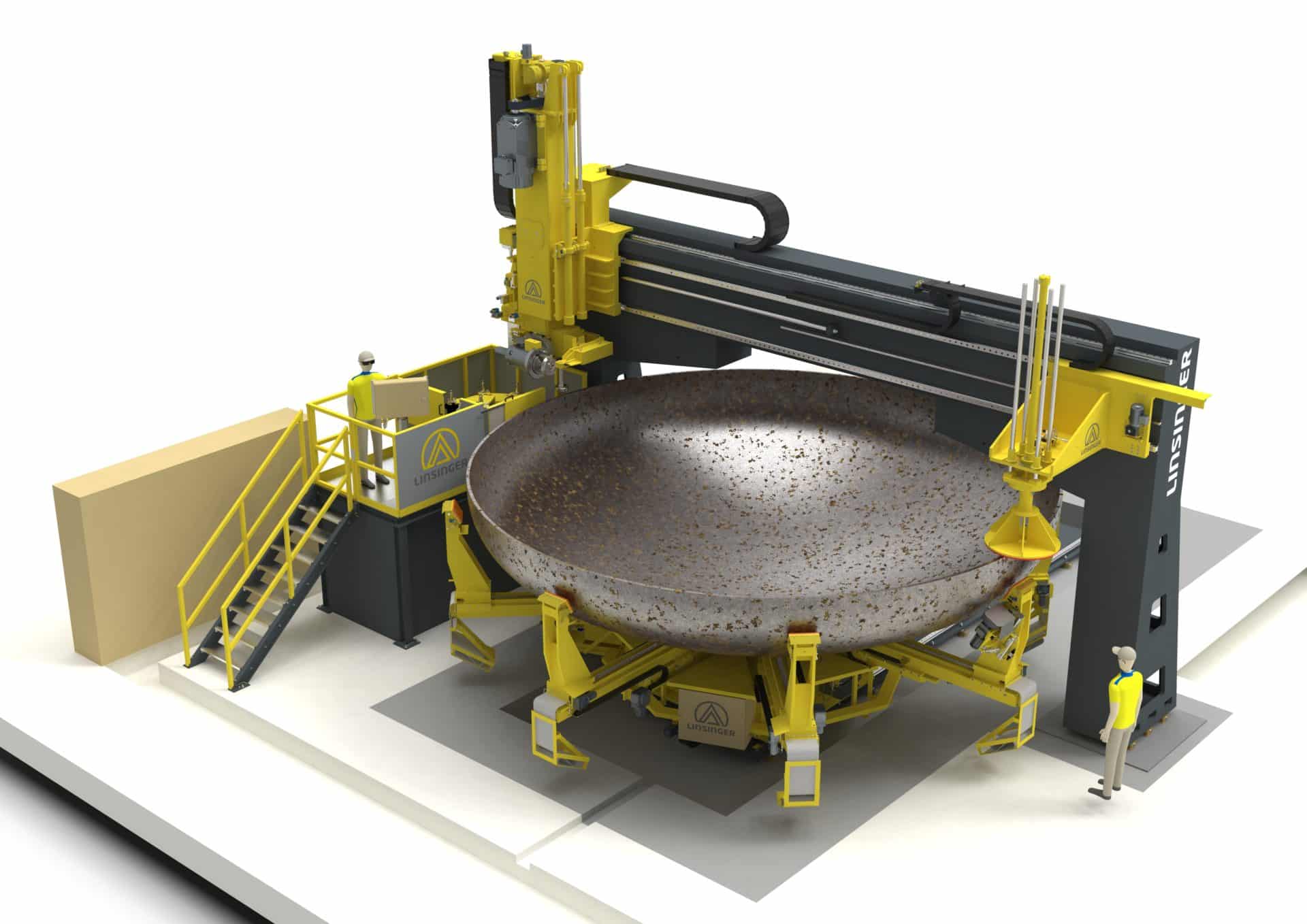

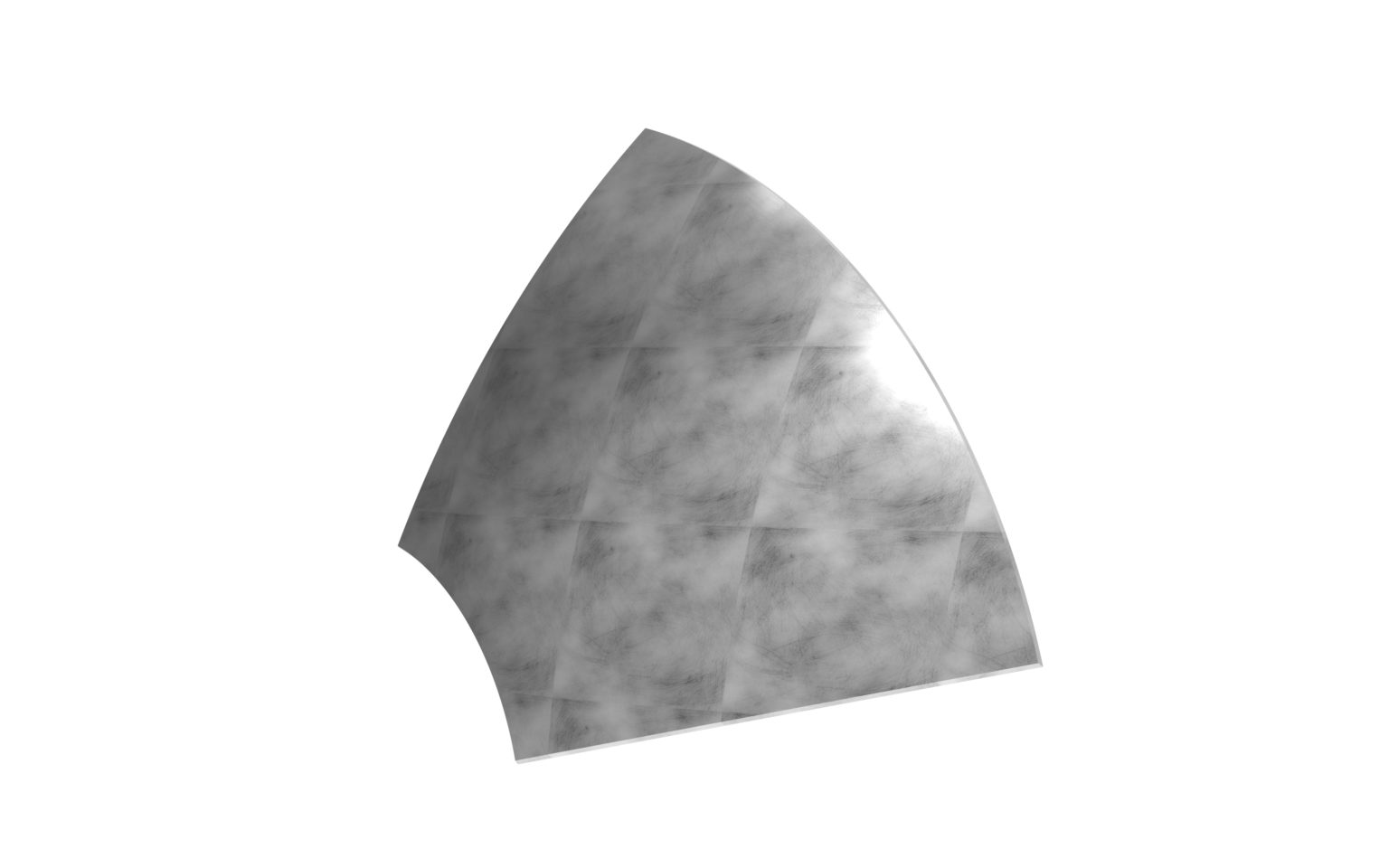

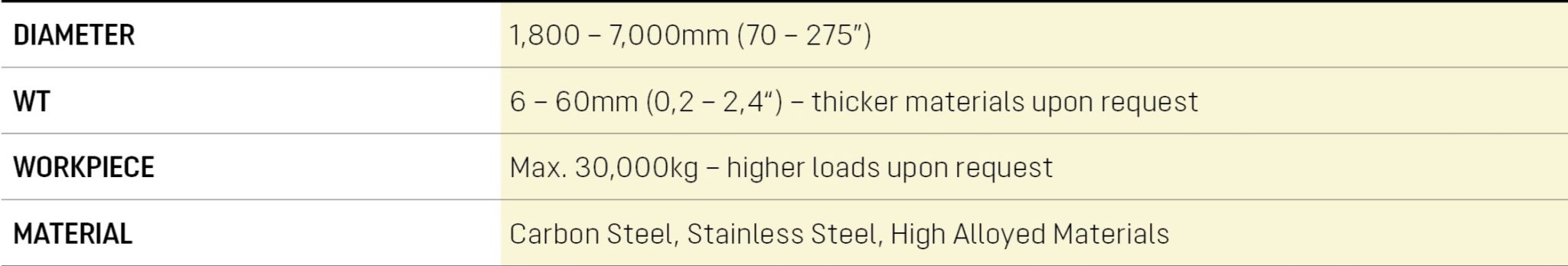

DIAMETER 1800 – 7000 MM

FEATURES

- Fully automatic machining cycle

- High bevelling performance

- Easy machine setup for every diameter

- Automatic and precise alignment of boiler ends

- Precise and fast welded seam preparation

- Various kinds of profiles available (V/X/Y/J…)

- Automatic tool changer function available

APPLICABLE FOR

AVAILABLE OPTIONS

- Milling of press tools for vessel heads

- Machining of centric or concentric holes by drilling or milling

- Threading and bevelling of holes

- Bevelling of holes

- Plane milling of flanges or surfaces after welding

- Milling of spherical tank segments

FR

FR