3-axis ultrashort pulse laser micro-milling system

The KLM-E1 is a 3-axis femtosecond laser micro-milling system based on a proven high-precision KERN motion platform and state-of-the-art laser micro-machining control software. The system is designed for accurate laser micro-milling of small workpieces.

Application areas include for example :

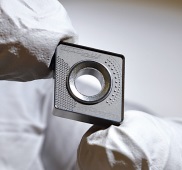

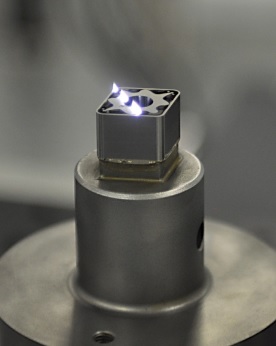

- tool production: carbide insert press tools

- coin production: embossing tools for coins

- watch industry: high precision forming tools and

individualized parts

Feature Highlights

ASPM

Automatic spot position and power measurements on the work table are used to automatically keep the machine in calibration and compensate for any drifts in the spot position or the laser power of the machine. This guarantees accuracy as well as stable and reproducible results on the long term.

Adaptive machining

The machined depth is measured during machining and deviations are compensated automatically. This significantly reduces the depth error in laser micro-milling, especially of deeper structures.

Laser process

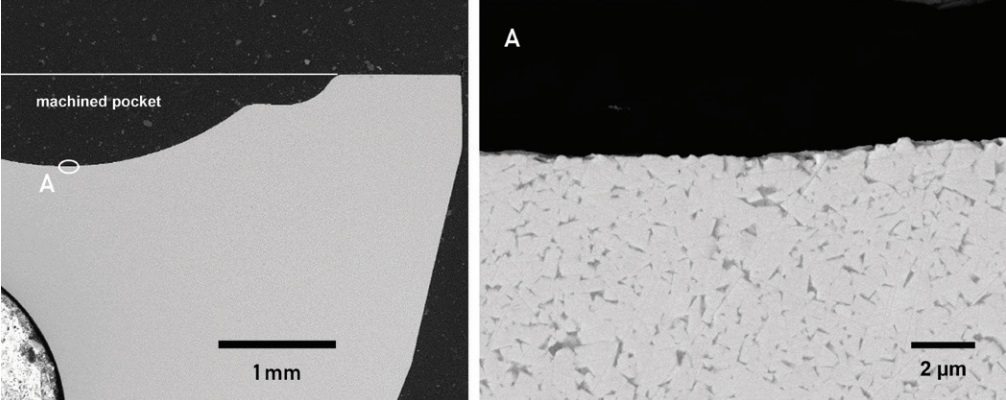

A laser process was specifically developed for machining cemented tungsten carbide insert press tools. It is both fast and precise – effective material removal rates of 1 mm³/min or higher can be achieved with a form accuracy better than ±10 µm and a low surface roughness. The ultrashort pulse laser process has a very small heat-affected zone with no significant sub-surface damage, which increases the tool life.

Machining of a typical insert press tool takes less than 2 hours, which results in a reduction of production costs by about 35% in comparison to EDM machining.

FR

FR