Axes : travels

- X-axis : 350 mm

- Y-axis : 220 mm

- Z-axis : 250 mm

- B-axis : -110° to +110° option -180° to +110°

- C-axis : 360° endless

Axes : Dynamics

- Vmax X, Y, Z : 30 m/min

- amax X, Y, Z : 10 m/s²

- vmax B : 100 1/min

- vmax C : 200 1/min

- vmax B : 100 1/min

- vmax C : 200 1/min

- full load torque B : 648 Nm

- constant torque B : 360 Nm

- Holding torque B-axis (clamped) : 300 Nm

- full load torque C : 135 Nm

- Continuous torque C : 75 Nm

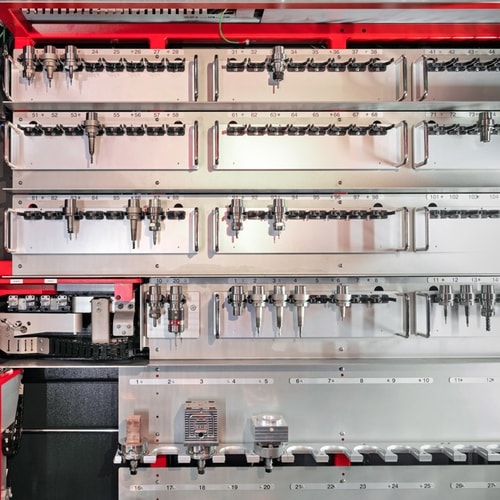

Automatic tool changer HSK 25

20 positions, 101 positions, 209 positions

-

- Tool changing time : < 3 s

- Chip to chip time : < 4,5 s

- Max. Tool diameter for automatic change : 70 mm (each 2nd tool rack position not in use)

- Max. Tool length for automatic changer incl. tool holder : 150 mm

Automatic tool changer HSK 40

18 positions , 90 positions, 186 positions

- Tool changing time : < 3 s

- Chip to chip time : < 4,5 s

- Max. Tool diameter for automatic change : 70 mm (each 2nd tool rack position not in use)

- Max. Tool length for automatic changer incl. tool holder : 150 mm

Numeric control

Spindle HSK 25

- nmax : 30,000 1/min

- nmax (optional) : 50,000 1/min

- Torquemax (S1) : 1.6 Nm

- Powermax (S1) : 6 kW

Spindle HSK 40

- nmax : 42,000 1/min

- Torquemax (S1) : 5.9 Nm

- Powermax (S1) : 15 kW

Spindle HSK 32

- nmax : 40,000 1/min

- Torquemax (S1) : 2.1 Nm

- Powermax (S1) : 6.3 kW

Clamping system on 5th axis

- EROWA Power Chuck P

- System 3R Magnum

FR

FR