High Precision CNC Machining Center for single-part and small series production

Efficient Manufacturing without limits

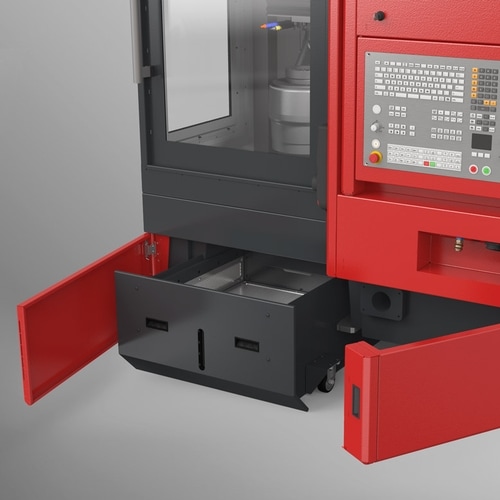

- Compact design and minimal space requirement of less than 5 sqm

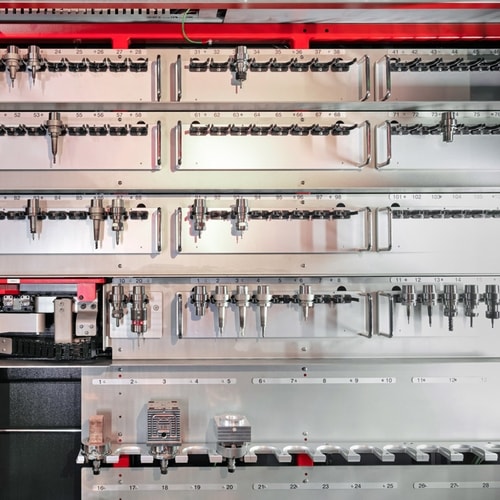

- Tool cabinet with quick-change pallets for up to 210 tools

- Interfaces for all common automation systems

- Advanced KERN temperature management

- Free access to machine chamber and machine table

- One-box Design

Technologies

New benchmark in precision manufacturing

With the newly developed micro-gap hydrostatics, the linear drives and the advanced KERN temperature management, the KERN Micro HD is the new benchmark in precision, long-term stability and dynamics. Together with the know-how of our customers and the knowledge of KERN engineers, the KERN Micro HD is unmatched.

Automation

KERN CNC machining centers have standardized interfaces for all common automation systems. It is easy to integrate a KERN machine into any existing production line, our machines offer the highest flexibility and safety for your automation task.

The automation of a KERN machine for tools and workpieces does not affect service in any way, the main door of the machine chamber remains accessible even while the machine is running.

Your Advantage

- 24/7 Reliable Serial Production

- Significant increase in turnover – also in night shifts

- One operator for many machines

With the new integrated workpiece changer of the KERN Micro, we provide a convenient route into automation.

Benefits of 100% integrated automation

- 24/7 Operation (nights & weekends)

- Amortisation in less than 12 months

- No additional footprint

- No additional software or interfaces necessary

- Benefit from the high process stability of the KERN Micro

Product Design

When designing our machine, we take into account all aspects of automated serial production – from automatic tool change to ergonomics at all access points.

Tool change

For fast and safe tool changes during the serial production, all KERN machines have the option of setting up the tool storage during machining. A large number of spaces for tools allows you long run times without staff, the tools are well arranged. The quick-change system of the KERN Micro is patented.

Ergonomics

The best accessibility and clamping height of each KERN machine ensure ergonomic working. The machine chamber is bright and accessible at all times with the main door, even when the machine is on an automated run.

Axle kinematics

The product design of the KERN machines takes into account best axis kinematics in order to minimize the traverse paths, especially for small 5-axis parts. The most economical linear axes possible and large swivel and rotary axes, as well as the arrangement of the axes, make it possible to produce even complicated free-form geometries with the shortest possible travel distances in one clamping.

Patented machine stands

The symmetrical portal construction of the KERN machines with a machine stand made of KERN-Armorith (mineral casting, reinforced with heavy steel struts) suppresses practically all vibrations that occur due to its weight and its patented material.

Temperature stability

KERN Microtechnik has developed a smart temperature management system for its machining centers which meets the requirements of each individual KERN machine.

With the help of our own software algorithms, the heat is dissipated where it is generated. As a result, KERN machines achieve a very high temperature stability.

The intelligent temperature control of the entire machine reduces thermal errors. It also includes the cooling lubricants, and is only one of the advantages of a KERN machine.

Your advantages

- zero and kinematic points remain over a long period of time – often over a machine life

- High process stability leads to significantly reduced cost in quality control

- Amortisation of your investment with high energy efficiency

FR

FR