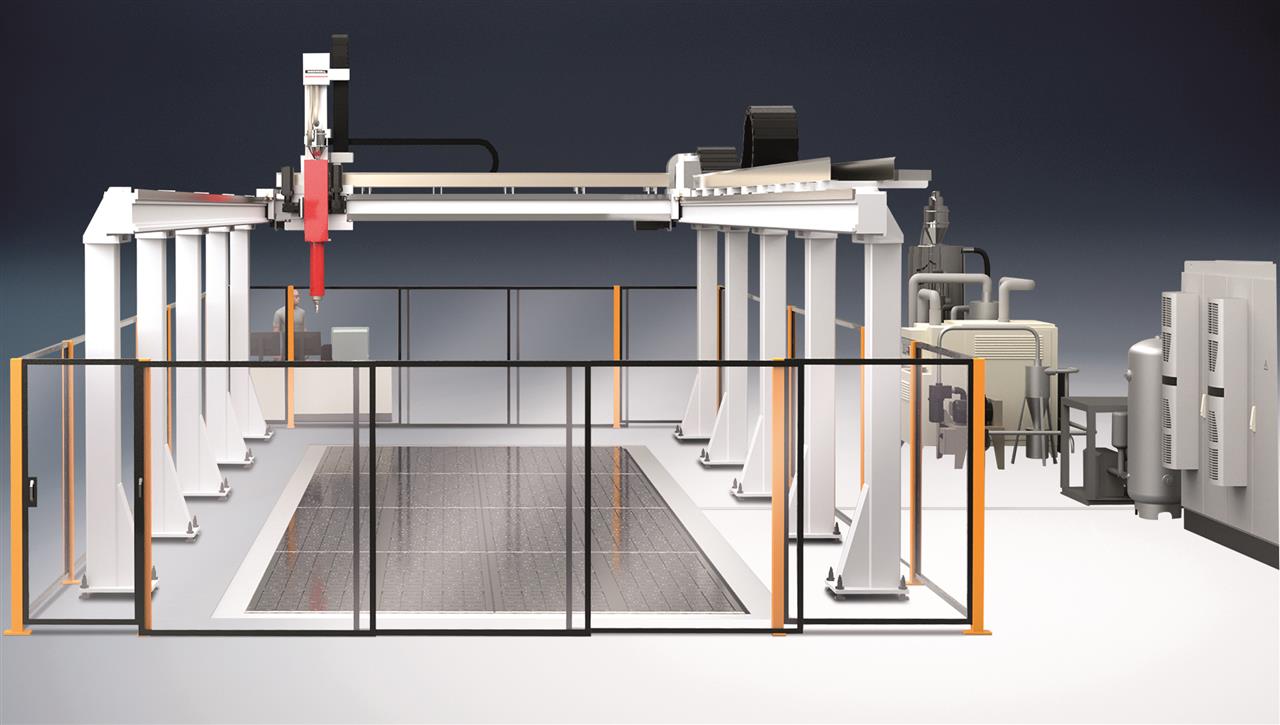

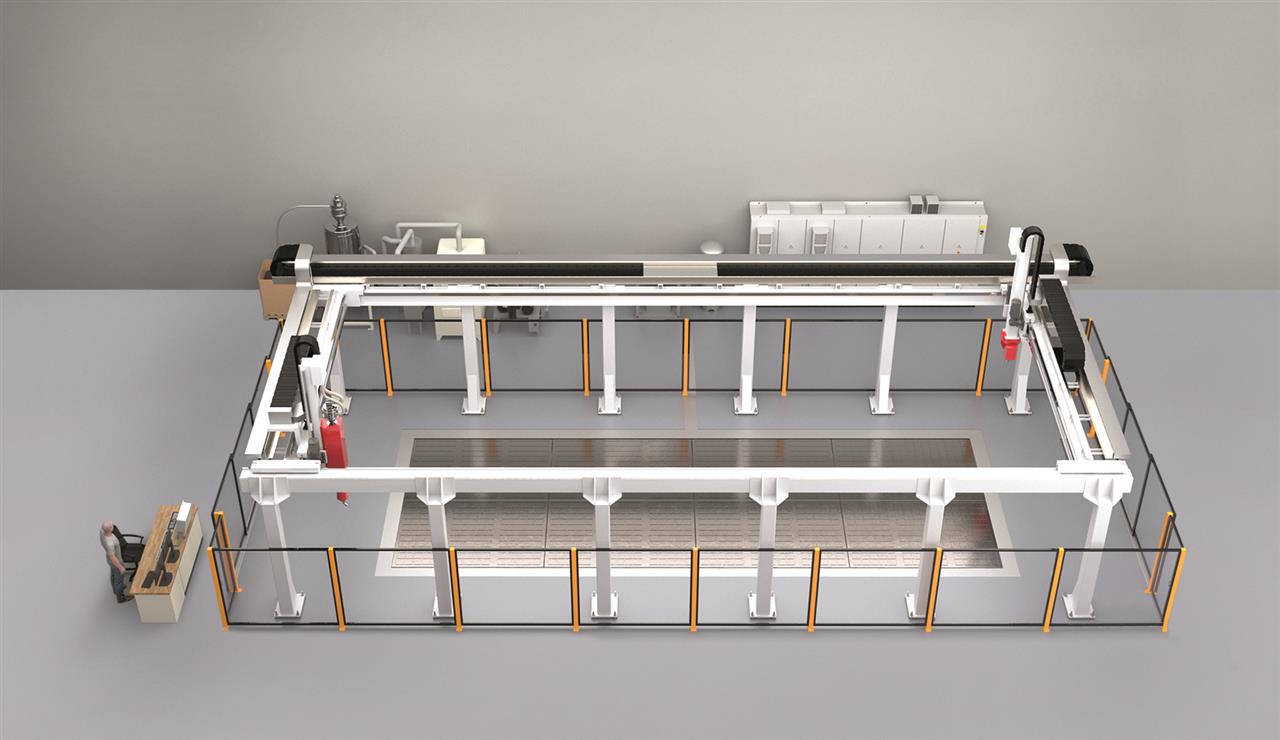

MasterPrint® Linear

MasterPrint® Linear is Ingersoll Machine Tools’ newborn in the MasterPrint® family that eases your company’s adoption of large-volume additive manufacturing technology.

With its innovative lean positioner, MasterPrint® Linear, while preserving all of the core features of MasterPrint® 3X (large volume, print at any angle, Siemens CNC), offers a smaller footprint and requires lighter foundations, lessening the risks and the investment for your organization.

MasterPrint® Linear provides your company with the ability to:

- print at an angle

- print at a variable angle extra-large composite parts in a single piece.

MasterPrint® Linear is aimed both at the fast prototyping and durable molds needs of space, aerospace and naval sectors, but can also serve a wider market, when printing cost-effectively, quickly, reliable wide-and-high parts is a requirement.

The MasterPrint® family of products has disrupted and transformed the traditional way to procure and manufacture extra-large tools by:

- shortening the lead time from months to weeks

- reducing manufacturing cost by 90% (no cutting, welding, stress relieving, minimal milling and assembly)

- fast-prototyping provisional tools for short programs and pre-production runs

- overprinting, re-milling, improving, re-using existing 3D-printed tools

- choosing and 3D-printing the polymers most suitable for your application

Configurations

- Siemens 840D and Sinumerik One CNCs

- Ingersoll proprietary software for programming, simulation, optimization and diagnostic

- Milling system (optional)

- Vacuum table (optional)

FR

FR