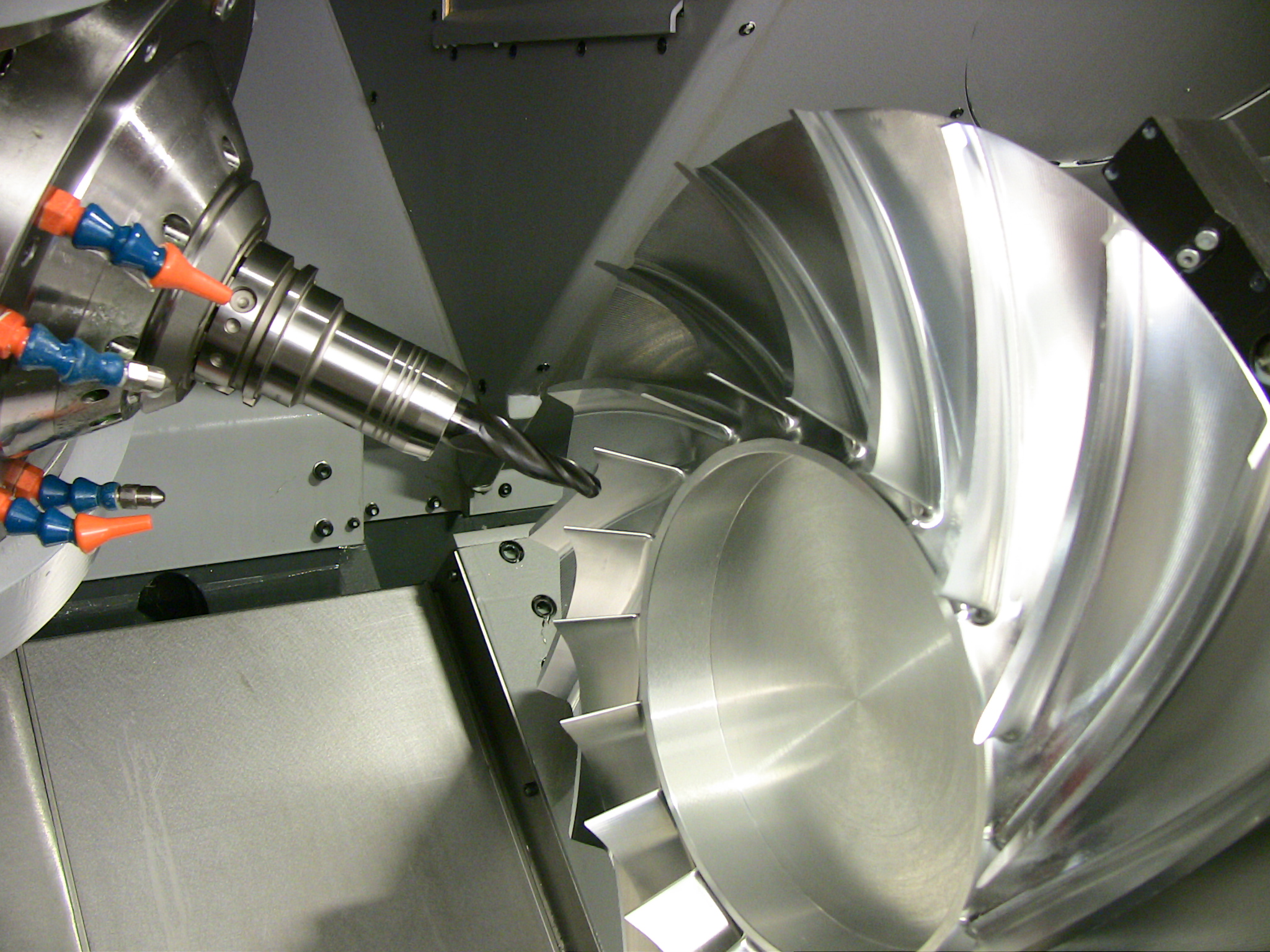

HAMUEL HSTM 150 S2

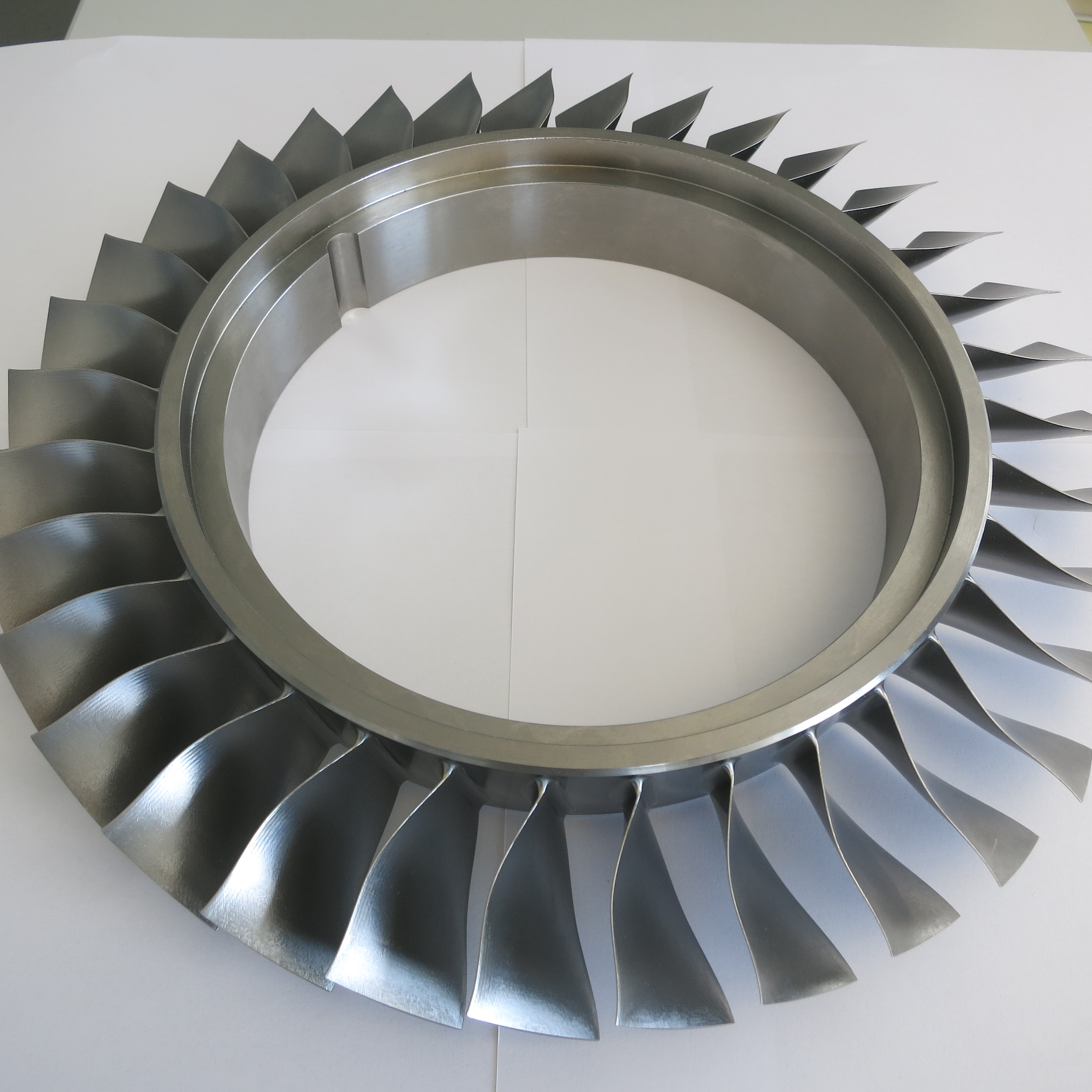

The machine meets the highest demands of modern blade machining, where the attainable accuracies and surface qualities are concerned. Its sturdiness and rigidity, along with the integrated HSC-support, warrant for utmost productivity. The compact machine design permits its quick and flexible installation at the customer factory – without any special requirements regarding the foundation.

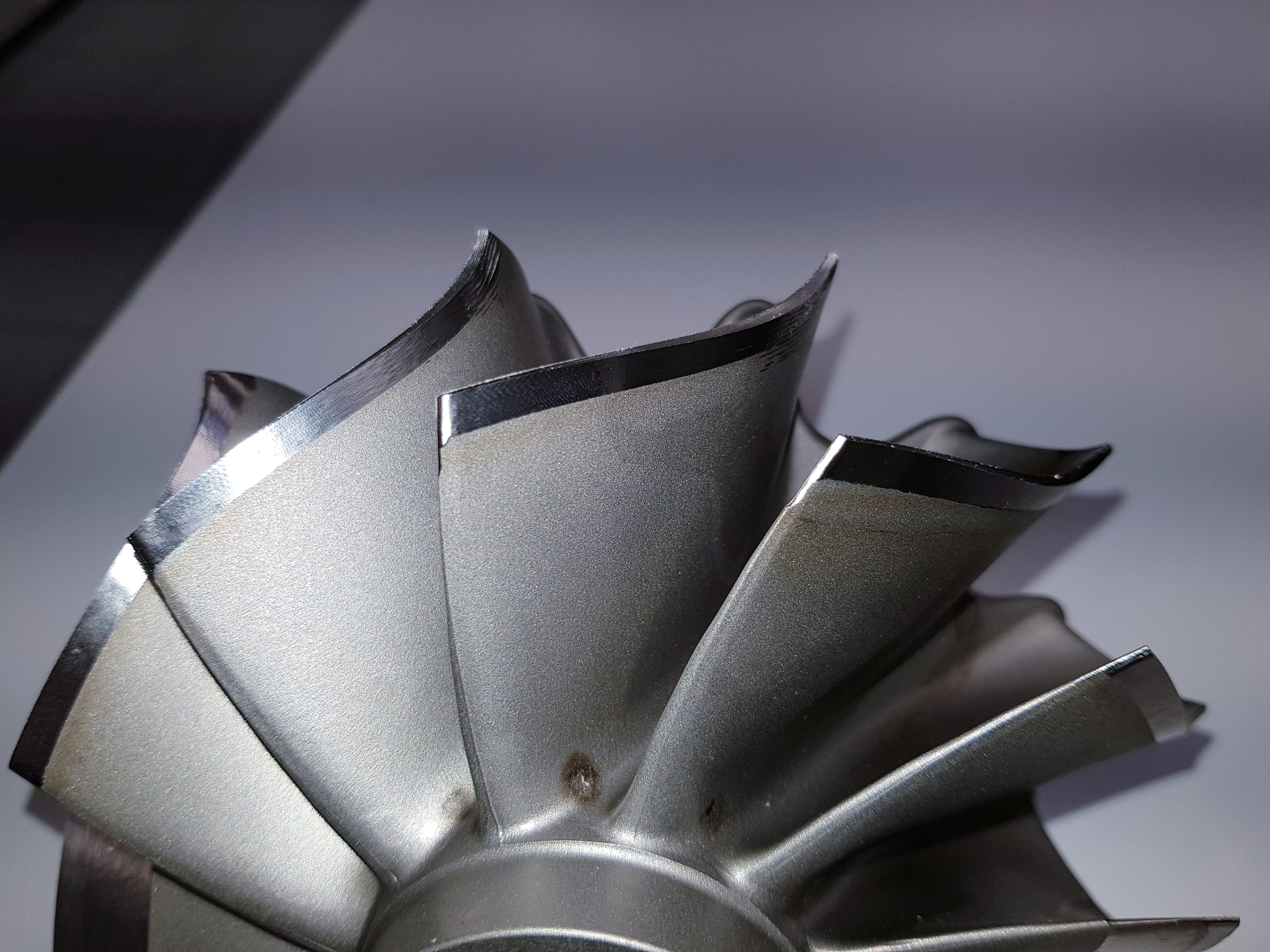

- Excellent surface quality owing to the rigid, low-vibration design

- Separation of work-piece (A, C, U) and tool axes (X, Y, Z, B) for utmost machine dynamics

- Identical kinematic and dynamic conditions for the X-, Y- and Z-axis

- Very good chip removal from the working area

- Quick installation and commissioning

- Maximum acceleration values up to 1g

- Mineral cast machine bed for excellent damping

- Consideration of the latest know-how for all operating and control elements

FR

FR