Small Details, Big Results

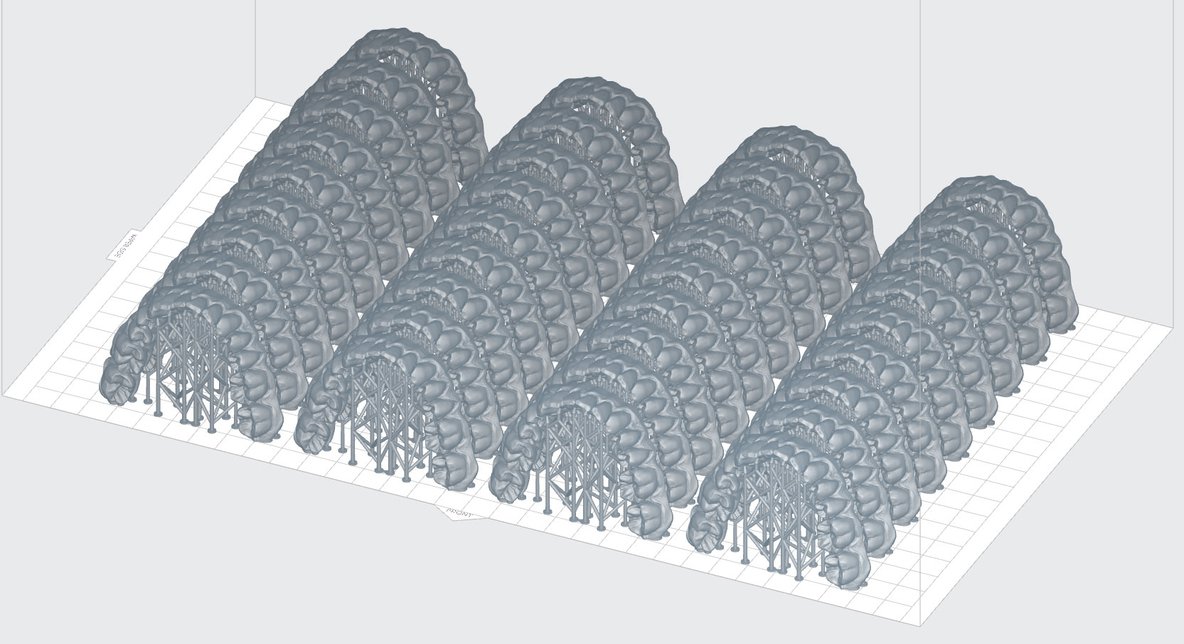

Perfectionism That Scales

With advanced Low Force Stereolithography (LFS)™ technology, Formlabs has completely re-engineered resin-based 3D printing to drastically reduce the forces of the print process.

Twice the Laser Power

Faster printing

The two LPUs work simultaneously along an optimized print path to efficiently blaze through parts of all sizes.

Crisp, clean features

Each high-density laser passes through a spatial filter to guarantee a clean laser spot.

Consistent precision

A parabolic mirror ensures that the laser prints perpendicular to the build plane, ensuring uniform print quality across the entire build platform.

Nonstop Printing

High material capacity

The Form 3L can hold two easy-to-switch resin cartridges, preventing interruptions during large print jobs.

Closed-loop calibration

Optical sensors continuously correct for scale and power, and can even detect dust.

User-replaceable components

The Light Processing Units, resin tank, rollers, and optics window can be replaced in-house, reducing the need for replacement printer shipments.

FR

FR