Best micro abrasive waterjet machining center in the world

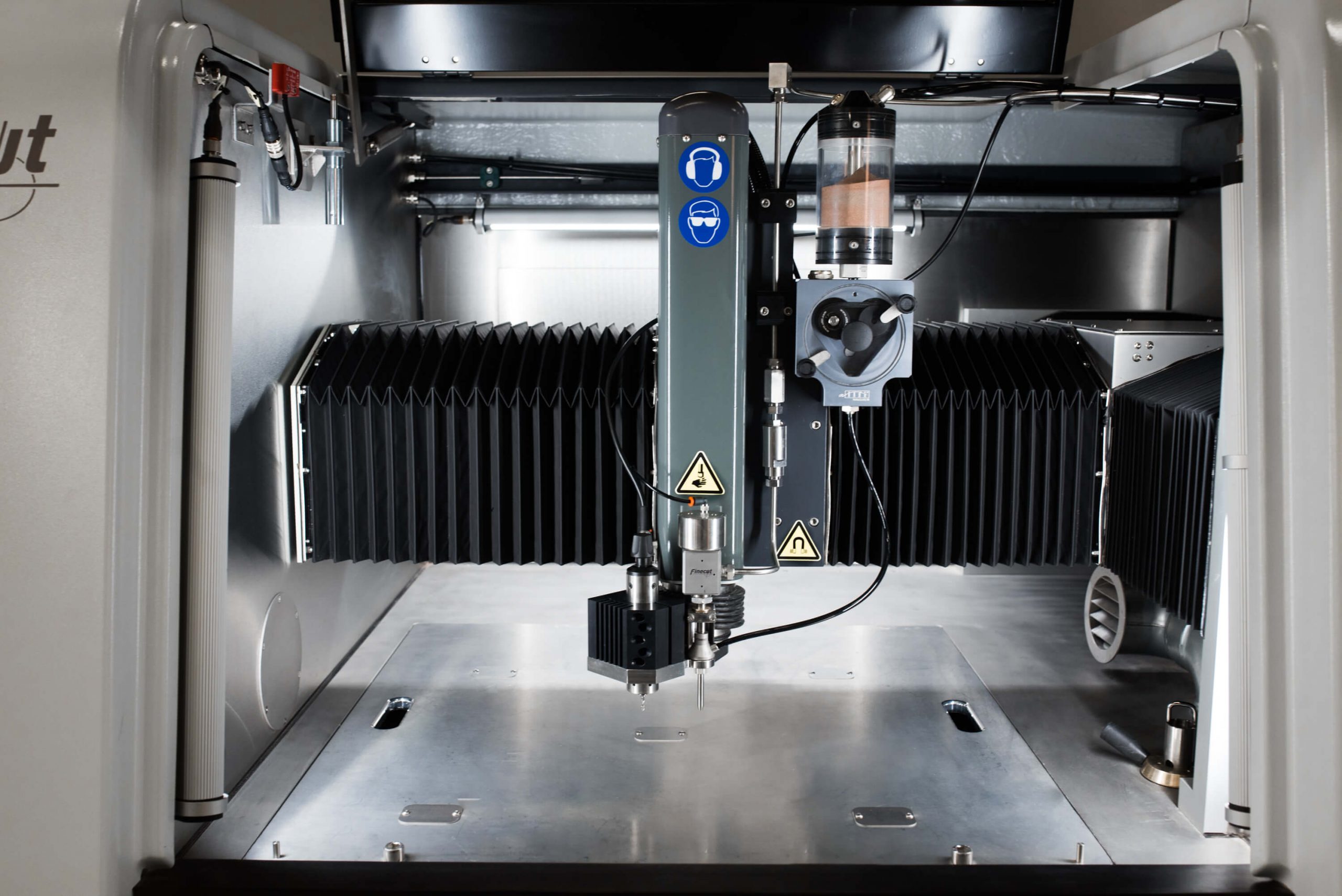

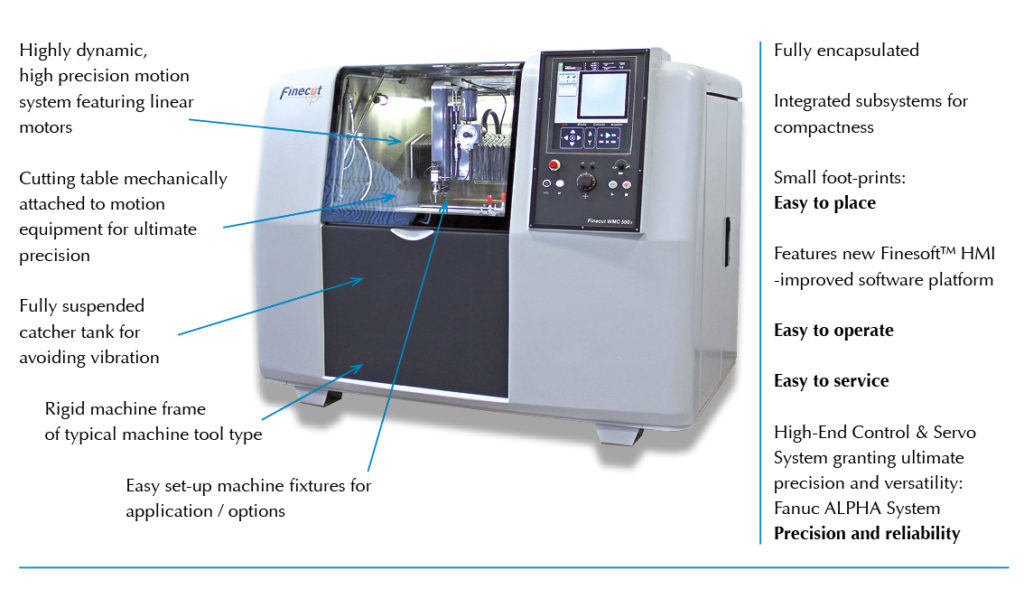

Finepart’s new generation of non-thermal micro abrasive waterjet machining center, the world leading Finecut WMC500II, is built by state-of-the-art components to provide capability for your ultimate precision cutting. The small footprint and encapsulated design make it suitable for any type of workshop environment alongside other CNC machines and sensitive equipment.

Standard Finecut machine configurations

Premium 3-axis system

-

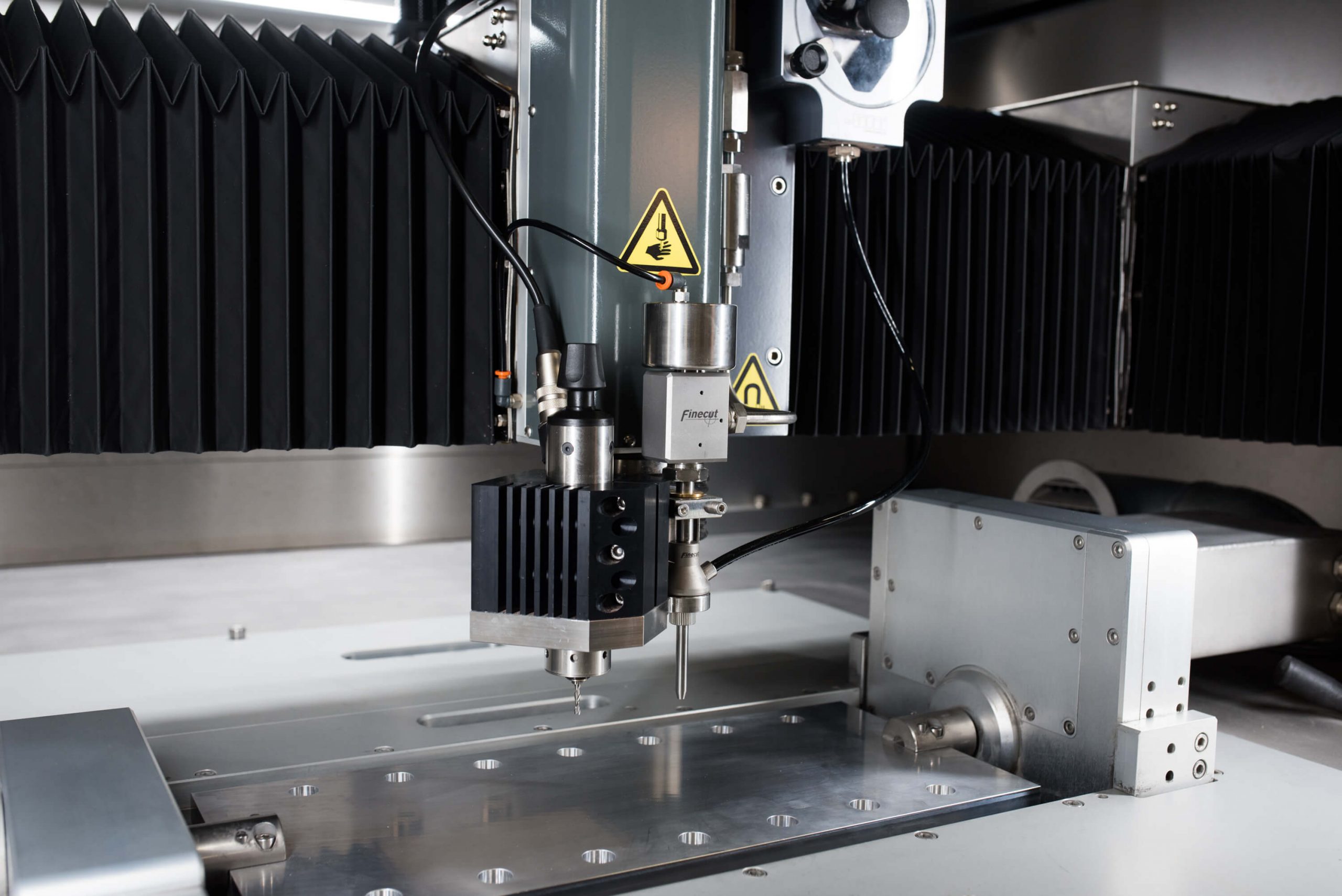

Cutting width down to 0.2 mm

-

Designed for ultimate precision

-

Highly dynamic and fully encapsulated motion system

-

Flexible fixtures for different applications

-

Intuitive HMI

-

Easy set-up. Easy to operate. Easy to service.

FINECUT WMC500II TYPE 4X

Precision with rotating work piece

-

4 axes working synchronously

-

Cutting width down to 0.2 mm

-

Live fixturing for cutting part from different sides

-

Rotates workpiece synchronously with cutting

-

High inclination angles

-

Utilizes 5-axis control with tool center point function

-

All functionality of the Finecut WMC500II type 4X

FINECUT WMC500II 5 AXIS TYPE ABX

For fast cutting without taper

-

Cutting width down to 0.2 mm

-

5-axis cutting with tool center point control

-

Boosts productivity with taper angle control

-

Corner optimization by jet motion strategy

-

All functionality of the Finecut WMC500II type 3X included

FINECUT WMC500II 5 AXIS TYPE B4X

For ultimate flexibility

-

Cutting width down to 0.2 mm

-

3 dimensional cutting

-

5-axis cutting with tool center point control

-

High inclination angles and complex shapes

-

Perfect for prototyping

Retrofitable options to all our machines

Finepart Sweden continuously develop new optional features in cooperation with our customers. You can always take part of the latest technology as we have the policy that all new options will be retrofittable to all machines in the Finecut WMC500II series. Options that are ordered with a new machine will be assembled with the machine and does not have any extra installation cost.

FR

FR