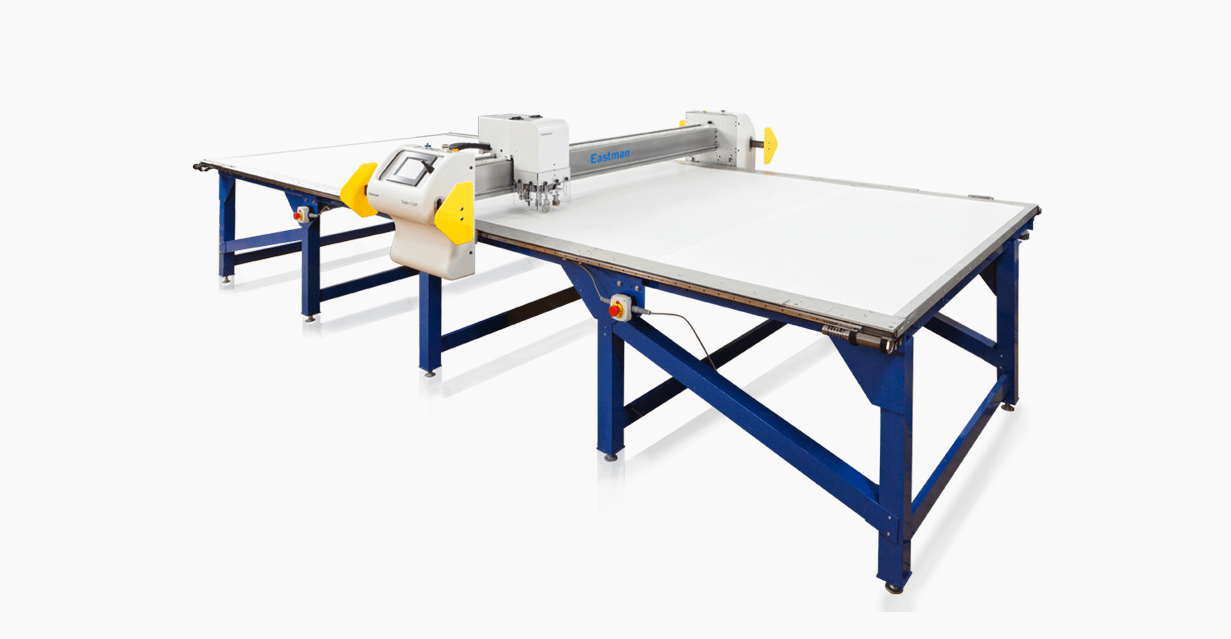

Static Table Cutting System S135

Eastman’s static table system is capable of cutting, marking, drilling and punching virtually any flexible material at speeds of up to 60 inches per second (152.4 cm/sec.). The static cutting table has proven itself as the go-to resource for materials like cotton, nylon and vinyl as well as difficult-to-cut materials—such as polystrand, p-tex, and fiberglass-polyester blends.

The system’s high-precision configuration features multi-axis motion for more defined and accurate cuts. Material is spread across the static table by an operator or with the use of a pneumatic gripper bar. The open plenum vacuum system design ensures evenly dispersed airflow for optimal material hold-down. This computer-controlled system features zoning capabilities to enable cutting in one area while the operator is simultaneously picking parts in another, maximizing daily production capacity.

The static table system is available in a range of system lengths and widths to meet the demands for prototypes, one-offs and full-production runs.

Features

- Choice of standard, heavy-duty or fiber tool head, featuring individually aligned and calibrated tool spindles with your choice of over 60 blades, punches and notches.

- A library feature within the operating control software allows the operator to save commonly used tool pressures and blade assignments based on job and material files.

- Prevent unauthorized changes to the system and software with restricted login access.

Cutting Surface

The standard cutting surface is a porous plastic sheet. Alternative cutting surfaces are available to optimize cutting results for any given material or aid in controlling material contamination concerns. Proven reliable for 2,000+ hours of normal operation use.

Material Hold-Down

The S135 is equipped with a high-flow vacuum system to ensure optimum material hold-down for cutting. The porous surface ensures evenly dispersed vacuum flow, no matter where you are cutting. Cutting zones may be designated so that cutting occurs in one area while piece removal takes place in another.

International Compliance Ratings

The operating computer and control cabinet are housed in an ergonomic enclosure that can be sealed to offer dust and water resistant protection in harsh or high particulate environments. Additionally, cabling connectors, servo motors and display components meet recognized international protection ratings requirements.

Industrial Design for Rigorous Use

- Advanced electro-pneumatic regulator for precise tool pressure control

- Heavy-duty cable connectors

- Easy access, sealed doors for inspection and maintenance

- Heavy-duty construction with scratch-resistant powder coated finish

- The series of drives is capable of Condition Based Predictive Maintenance. This is the practice of detecting changes in machine vibration and friction of your belt drives, linear guides, and gears so that parts can be replaced accordingly before they fail. This function automatically generates a failure warning limit so machine operators can schedule a service call to prevent machine downtime.

Safety

- Four remote emergency stops: two on cutting gantry, two system-mounted

- Additional gantry-mounted stop disks pause system operation until returned to neutral and reset. Operation can then be resumed from any position

- Tool head is equipped with plexiglass safety window to keep hands free of knife during operation

- Single turn-off point with a universal power system for lockout / tagout safeguards employees from unexpected start-up

FR

FR