BIGREP IPSO 105

Reliable tooling production and more

The IPSO 105 is a versatile, high-temperature industrial machine with unbeatable value for money. It is the most automated, reliable and fastest way to get robust, high-performance parts into the hands of engineers and industrial designers.

Aptly named the toolmaker’s tool, it is a breathtaking machine with a 105-litre volume reaching 100°C and a print bed heated to 180°C. It is designed with state-of-the-art dual extruders capable of printing high-performance materials with open access to the world’s most advanced materials, including PC, PEKK and PEKK-CF.

AEROSPACE QUALITY PARTS

AEROSPACE QUALITY PARTS

Innovate and qualify for certification in the aerospace industry. The IPSO 105 prints with high-performance materials to create solid, safe and lightweight parts. High accuracy, repeatability and resolution enable innovation at every stage of the design workflow.

FUNCTIONAL PROTOTYPES

Before moving on to final production, test designs and validate parts. The open material system gives you the freedom to choose from a wide variety of filaments and accurately reproduce the final part. Iterate faster, reduce manufacturing costs and get your products to market faster.

DURABLE TOOLING

Quickly produce low-cost tooling for your factory, such as jigs. With high-temperature capabilities, you can produce robust, complex tooling in-house. Overcome outdated traditional techniques and print-on-demand tooling.

LARGE-SCALE 3D PRINTING

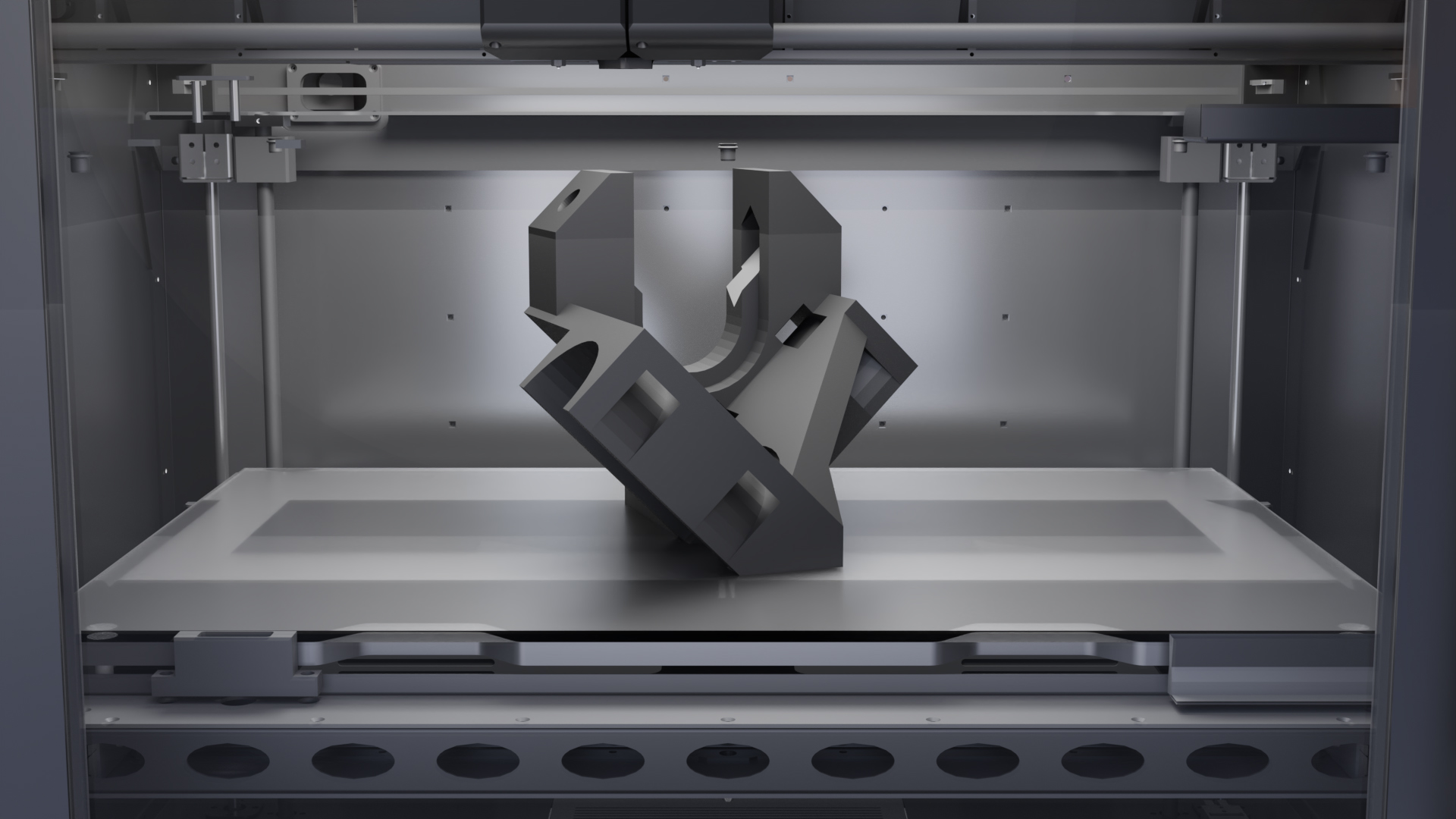

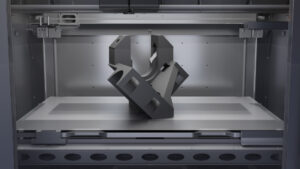

THE BUILD VOLUME OF A TOOLMAKER

With a build chamber of 400 mm x 600 mm x 440 m (105-litre print volume), IPSO is somewhere between a desktop machine and a large-format 3D printer, perfect for many toolmaking applications. With industrial components built to last and stepper motors with encoders, IPSO 105 achieves the level of precision and repeatability you expect from an industrial machine.

HIGH-TEMPERATURE CAPABILITIES

HIGH-PERFORMANCE PARTS

The advanced high-temperature capabilities of the IPSO 105 include a build chamber reaching temperatures of up to 100°C, 180°C print bed heating and 450°C extruder temperature capability. This versatility and precision enable the widest range of applications with an unlimited number of materials, from technical-grade parts to functional prototypes.

TWO RELIABLE DSX EXTRUDERS

UNINTERRUPTED PRODUCTIVITY

The 2 DSX (Direct Synchronised Extruders) are capable of printing at 450°C and feature integrated cooling channels and multiple sensors for monitoring and control. When the filament runs out, the relay mode comes into play and the second extruder seamlessly takes over. DSX extruders are particularly good with soft and flexible materials (up to 70A) thanks to their short filament path and optimised feed mechanism.

FULLY AUTOMATED QUICK START

PRINT AT THE TOUCH OF A BUTTON

Start-up is quick and easy, thanks to a host of automatic functions such as bed calibration via topology measurement and automatic compensation. After a smooth start-up, a host of built-in sensors will secure your operation 24/7, while the wide-angle HD camera allows real-time remote monitoring so you don’t miss a thing.

HEATED PRINT BED

SEVERAL OPTIONS FOR OPTIMUM ADHESION

Enhance your printing success with a uniformly heated print bed offering two optional print surfaces:

– A specialised tempered glass plate with minimal thermal expansion for more accurate printing on a wide range of materials.

– The other is a flexible steel plate with a magnetic foil and PEI coating for easy print removal.

UNIFORM TEMPERATURE DISTRIBUTION

PRECISE, UNIFORM PARTS

Consistent temperature is essential for excellent prints and a requirement for high performance parts. Reaching temperatures of up to 180°C, the IPSO 105‘s print bed maintains even heat distribution. The well-insulated manufacturing chamber circulates heated air up to 100°C for optimum mechanical performance and print quality.

- Discover the educational and technical content available on their website by clicking HERE.

FR

FR