Welding Acoustic Monitoring Technology

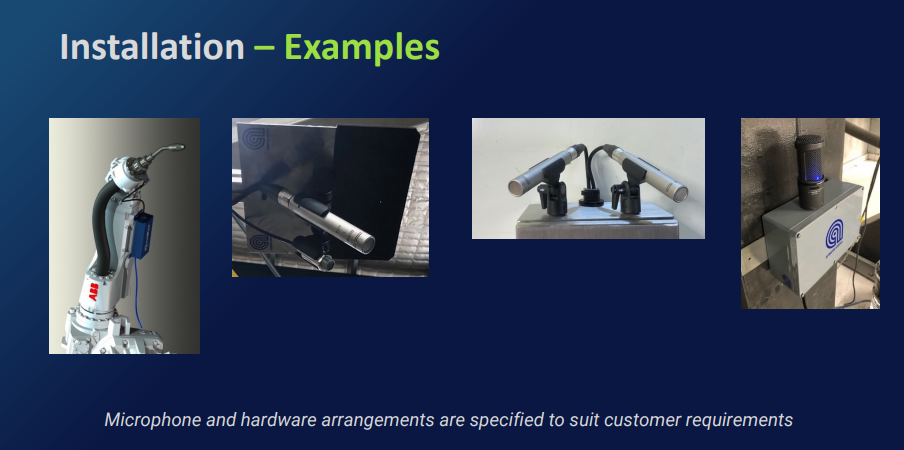

Automation Acoustics develops a solution for monitoring welding processes using a sound sensor. This sound is then analysed using noise suppression, a method proposed by Automation Acoustics following the constitution of a sound library and studies already carried out. The detection of defects is done through the study of noise that differs from a model signal. Models of the most critical and frequent faults must be established beforehand and reproduced for calibration. The technology does not require any special media and can pick up sounds up to 1m away from the weld.

Automation Acoustics’ particularity is to master the method of linking abnormal sounds in real time with the parameters of the machine used (intensity, distance of the torch from the part, etc.).

Alerts are created and listed in an alert log to keep track of defects.

Main features and benefits of Automation Acoustics

- One of the most advanced signal processing systems for welding acoustic emissions.

- Filters out irrelevant acoustic data, presenting only critically important data.

- Acoustic weld monitoring system capable of providing real-time feedback on monitoring data.

- Fully customisable operator HMI and management dashboard.

- Full data fusion capability with other data streams.

FR

FR